7

INTRODUCTION TO

OIL FREE AMBIENT AIR COMPRESSORS

Hycomp oil free ambient air compressors (compressors

taking their inlet from the air around you) are unique

in the industry due to their small size, extended lower

end life, and open crosshead design. The crankcase is

pressure oil lubricated, providing extended bearing life

in the main, connecting rod and wrist pin bearings. The

open crosshead allows any oil vapors that may escape

from the crankcase to be vented to atmosphere,

thereby preventing their entrainment in the compressed

gas stream.

Hycomp oil free compressors are designed for heavy,

industrial duty service. Slower compressor speeds

prevent heat buildup, increase valve effi ciency, and

increase overall life expectancy of wearing parts.

Hycomp’s crosshead design places the side thrust

developed by the connecting rod onto the oil lubricated

crosshead piston/cylinder. By removing this side

thrust from the compression piston, the piston rings

provide an extended life expectancy, in comparison to

permanently sealed ball bearing, ‘oil-less’ designs.

Hycomp air compressor cylinders and cylinder heads

are single piece iron castings. This significantly

decreases warpage problems associated with

aluminum cylinders/heads. Additionally, iron is

inherently vibration dampening.

All Hycomp air compressors are tested at the factory

to ensure they meet contractual requirements. When

properly installed, the air compressor should be ready

and able to provide the reliable service Hycomp

customers have come to trust and appreciate.

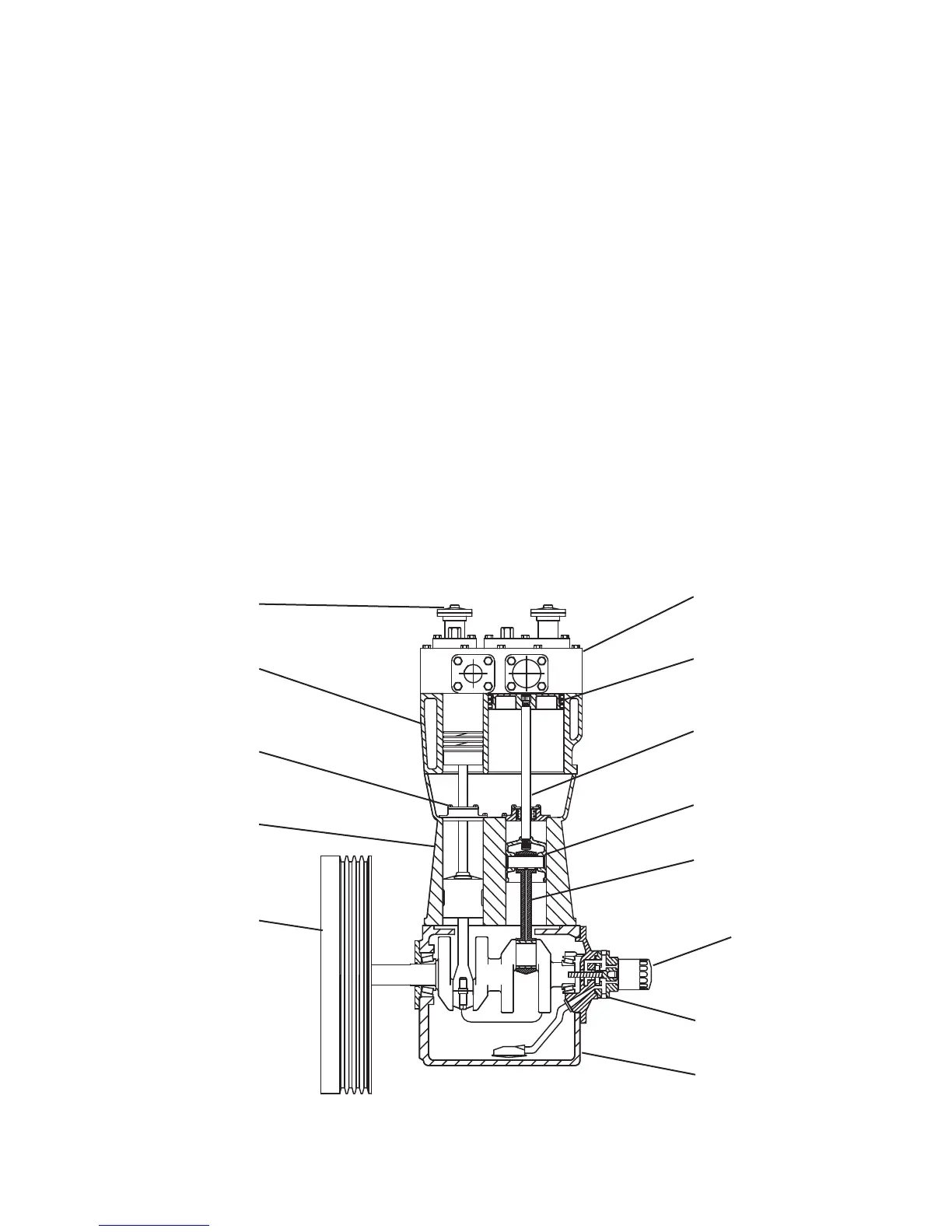

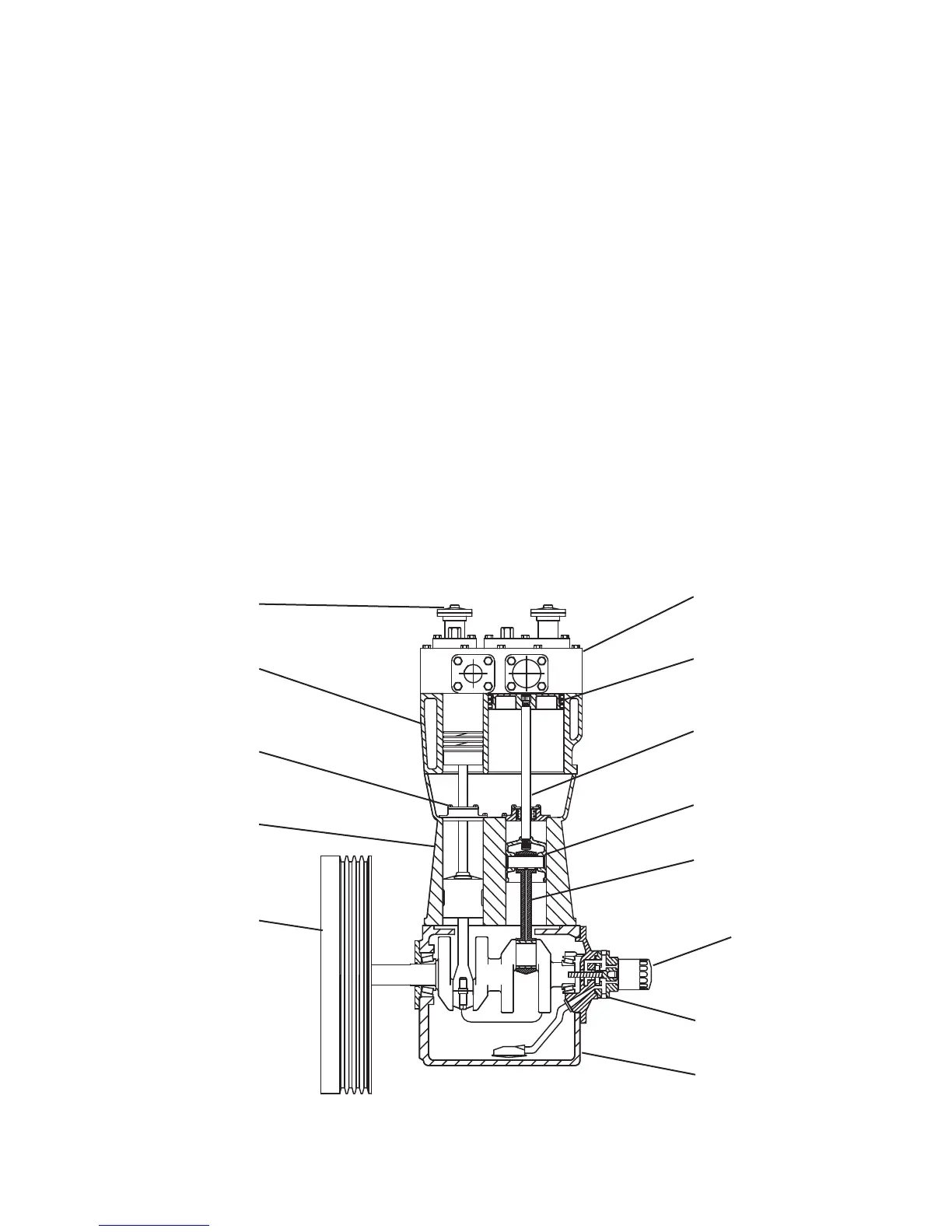

CYLINDER HEAD

OIL PUMP

COMPRESSION

CYLINDER

FLYWHEEL

CROSSHEAD

CYLINDER

OIL-SCRAPERS

UNLOADER

TOWER

COMPRESSION

PISTON

CRANKCASE

CONNECTING

ROD

CROSSHEAD

PISTON

OIL FILTER

PISTON ROD

Figure 1: Cutaway of an ambient Air Compressor

Loading...

Loading...