14

when penetrating the enclosure.

Motor Starter – The motor starter must have

appropriate electrical service brought to it by a qualifi ed

electrician. Hycomp control panels list the electrical

service required on a sticker near the starter.

Gas Pressure Switches or Transducers – Generally

located in the control panel, these are used to provide

control feedback to maintain pressure setpoints. Gas

pressure sensing lines of appropriate pressure rating

must be plumbed to the switch or transducer from an

appropriate point of origin. Use minimum 3/8” tubing.

The switches/transducers must be plumbed to a NON-

PULSING source to prevent false readings. Ideally, the

point of origin will be the inlet and discharge receivers.

It is NOT ACCEPTABLE to plumb these switches to

the compressor inlet and discharge piping, as the gas

in this piping pulses.

Unloader Device – The Hycomp control system

generally includes an unloader device to allow loading

and unloading of the compressor system. See the next

section for unloader methods and proper installation

of the device.

UNLOADER CONTROLS

Hycomp compressors are often supplied with an

unloading device of some type. This unloading device

allows the compressor to load and unload based upon

discharge and suction pressures, as well as allowing

the compressor to start and stop unloaded. Even if the

unit does not include a control system from the factory,

many Hycomp compressors have unloader devices

installed. A piping and instrument diagram (P&ID) is

generally including with every Hycomp compressor

system, showing unloader installation

SUCTION VALVE UNLOADING

Suction valve unloaders utilize unloading towers

attached to the compressor cylinder head, and a

three way valve to supply air pressure to the unloader

towers to actuate them. The tower forces the suction

valve open, allowing the compressor to unload. The

three-way valve supplies gas pressure to the unloader

towers, or dumps that pressure out of the unloader

towers (See Figure 7).

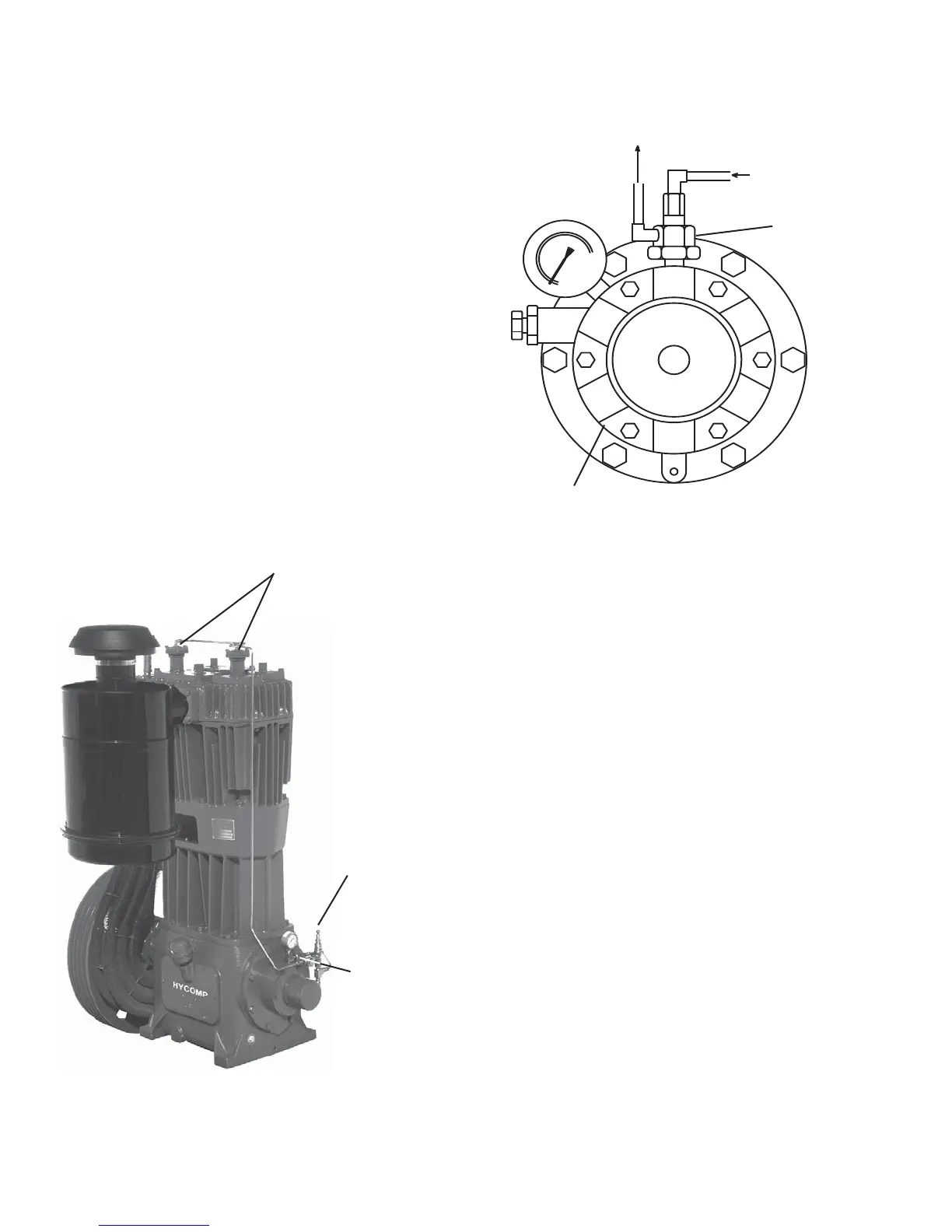

Unloader Tower – Provided on all pressure lubricated

Hycomp model ambient air compressors and provided

on some air booster and gas compressors. If the

Unloader

Towers

Constant Speed

Unloader (Pilot

Valve)

Hydraulic

Unloader

Valve

Oil Pump

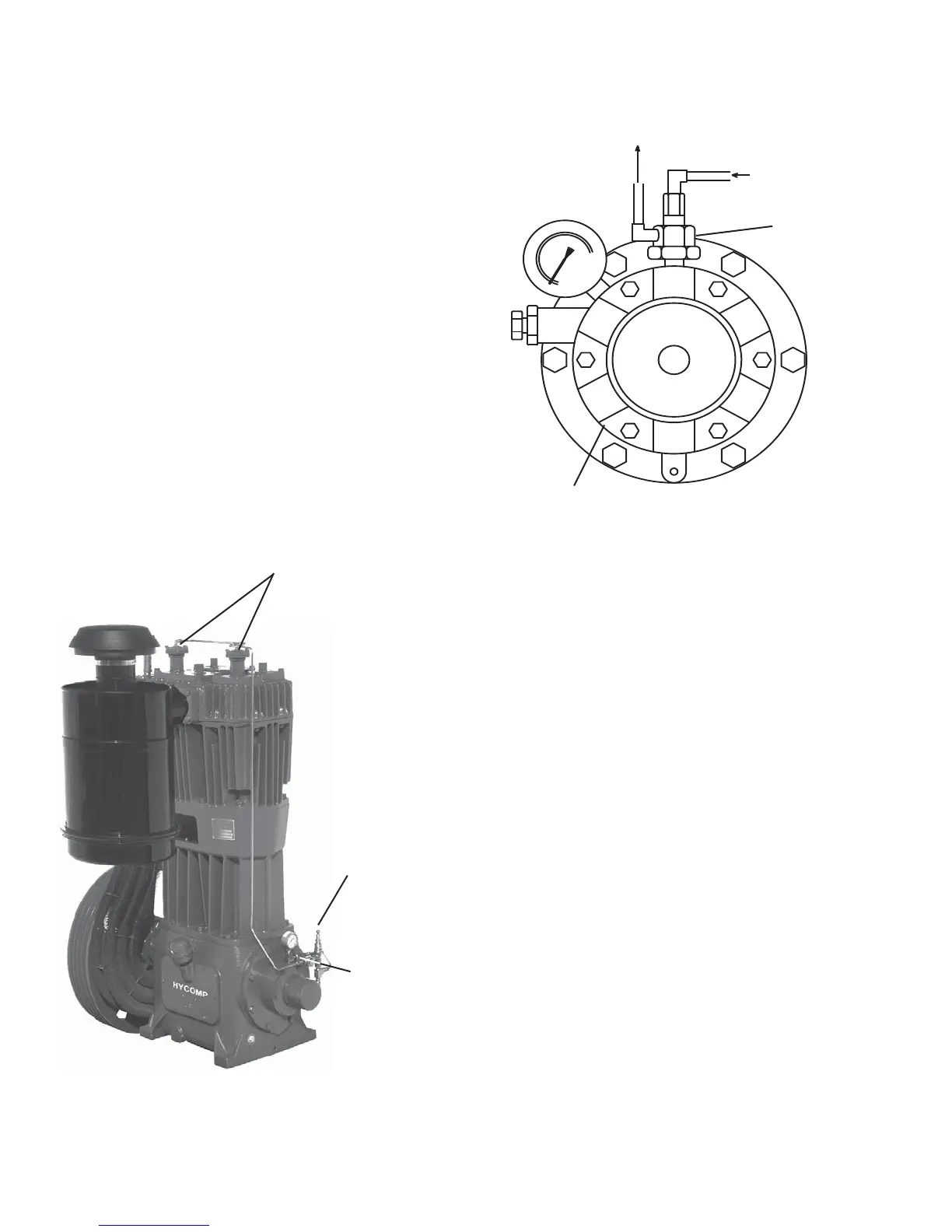

Figure 8: Hydraulic Unloader Plumbing

To air source

To Unloader Towers or

3-way Check Valve

Hydraulic

Unloader

Valve

Figure 7: Unloader Device Locations

Loading...

Loading...