15

unit unloads via Suction Valve Unloading, this item

is included. Located on the inlet valve covers, the

tower provides the mechanical motion (pneumatically

driven via a diaphragm) to physically open the inlet

valve(s). 1, 2 or 4 towers are employed depending

upon the model of compressor. This tower must be

supplied with gas pressure to operate the suction valve

unloaders. The unloader gas pressure must exceed

the inlet pressure by a minimum of 30 psig in order for

the unloader mechanism to operate effectively. If the

unit comes with an unloading valve of some type, the

plumbing from the valve to the towers is done at the

factory. If no unloading valve device is present, use a

minimum of 1/4” tube of appropriate pressure rating, to

supply unloading gas/air to the unloader towers.

Hydraulic Unloader Valve – Provided on all pressure

lubricated Hycomp model ambient air compressors and

some air boosters and gas compressors. Located at

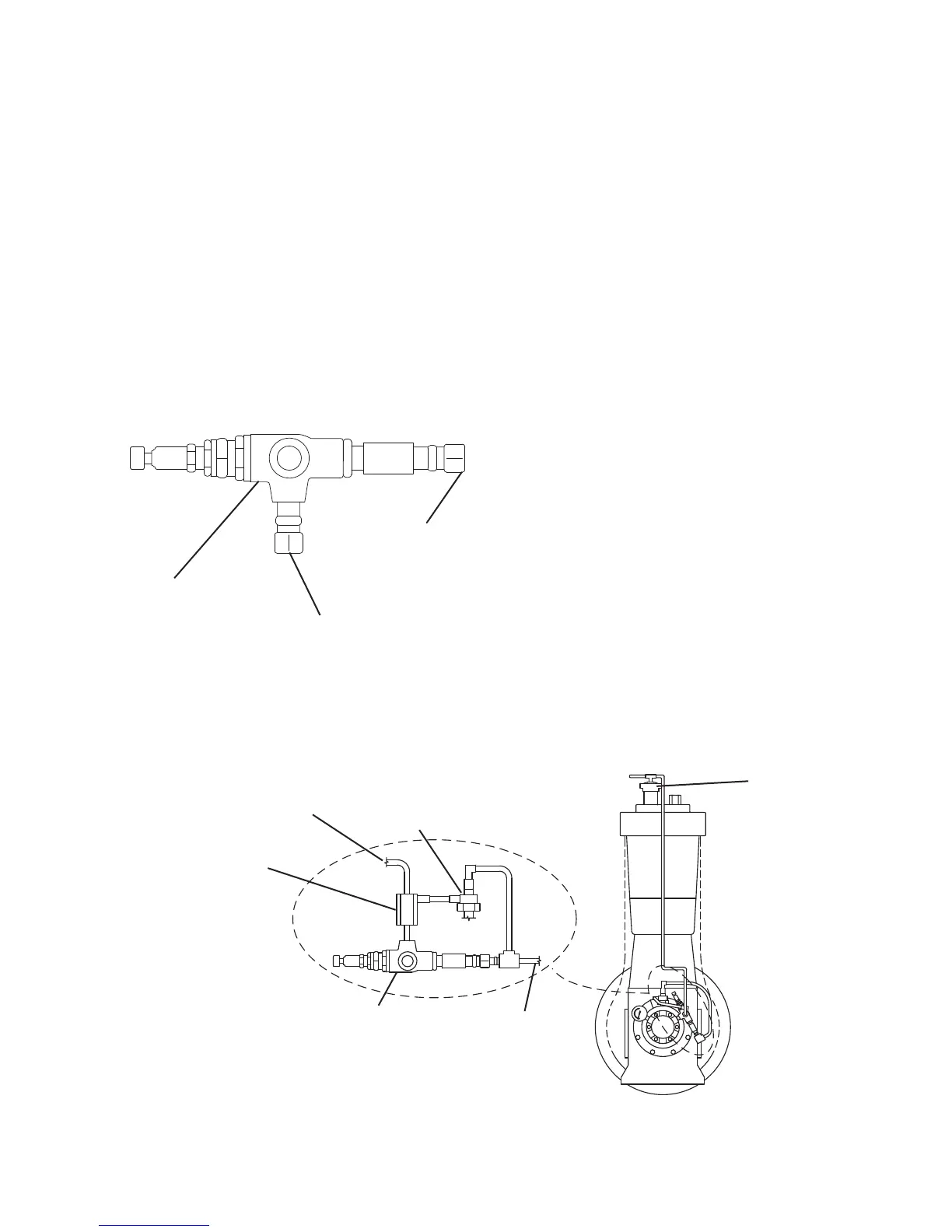

Figure 9: Constant Speed Unloader (Pilot

Valve)

Constant Speed

Unloader Valve (Pilot

Valve)

Connect to Unloader

Towers or 3-Way

Check Valve

Connect to Air

Receiver

the top of the oil pump housing, this unloader valve

senses oil pressure and supplies unloading pressure

to the unloading towers, when there is not suffi cient oil

pressure (see Figures 7 and 8). When the oil pressure

rises, the hydraulic unloader valve vents the unloader

pressure to atmosphere. This provides protection to

the compressor in the event of a potentially damaging

oil pressure drop. It also insures the compressor will

not begin compression until oil pressure has risen to

an acceptable level. THIS VALVE IS ONLY TO BE

USED WHEN THE UNLOADER GAS IS AIR OR A

NON-CONTAMINATING GAS THAT CAN BE SAFELY

RELEASED TO THE LOCAL ENVIRONMENT.

Constant Speed Unloader (Pilot Valve) – Provided

upon request for any Hycomp model air compressor.

Not used on air boosters or gas compressors. Located

on the side of the oil pump housing, this unloader

valve senses discharge receiver pressure and sends

pressure to the unloader towers when the receiver

pressure is adequate. When receiver pressure falls

below the required pressure, the pilot valve vents

the unloader pressure to atmosphere. Connect the

inlet to the discharge air receiver, and the outlet to

the unloader towers or a three way check valve. The

pilot valve is used when an air compressor is to run

continuously and a minimum operating pressure is to

be maintained. The pilot valve is not used on air or

gas booster compressors. THIS VALVE IS ONLY TO

BE USED WHEN THE UNLOADER GAS IS AIR OR A

NON-CONTAMINATING GAS THAT CAN BE SAFELY

RELEASED TO THE LOCAL ENVIRONMENT.

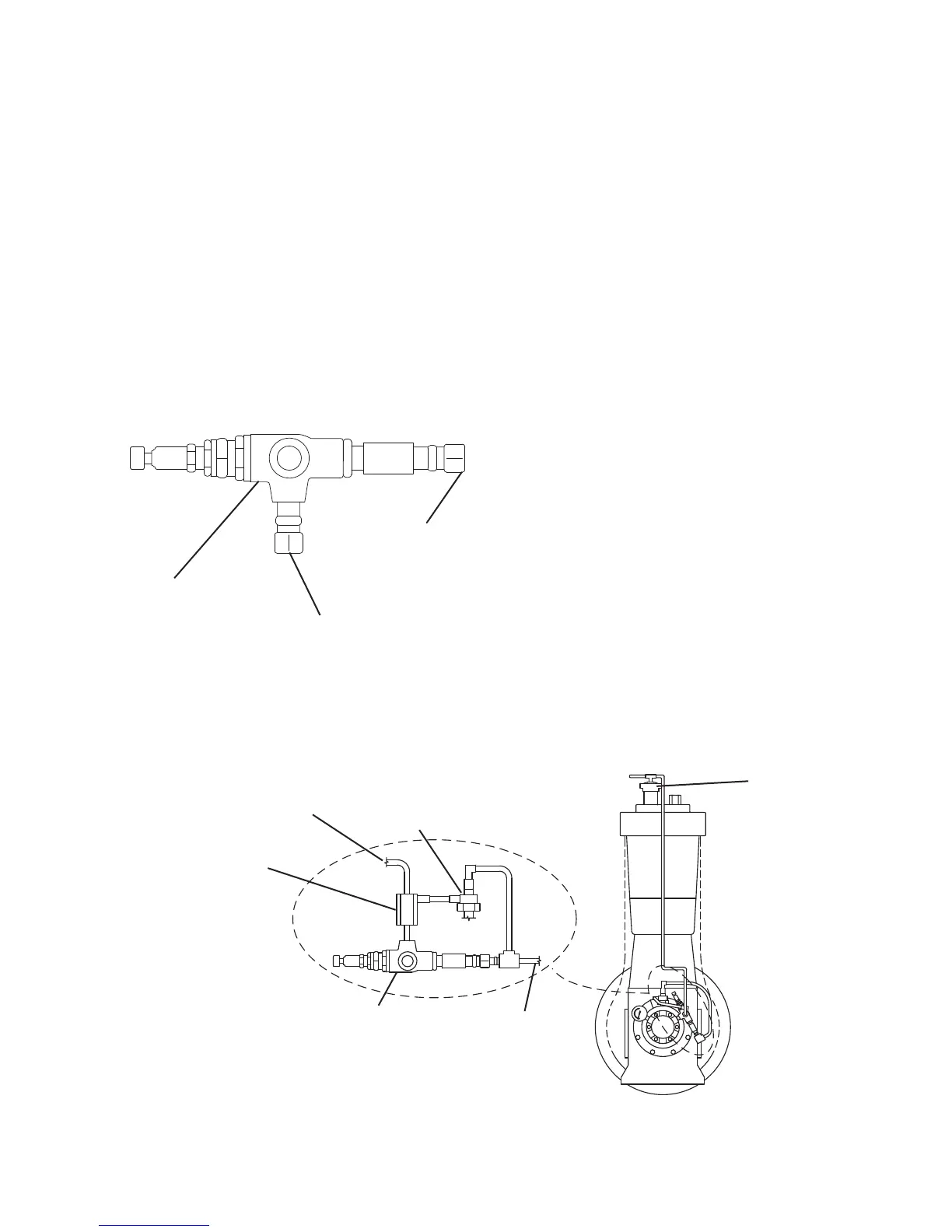

Figure 10: Dual Control - Constant Speed Unloader and Hydraulic Unloader

To Unloader

Towers

To Air

Receiver

Constant Speed

Unloader Valve

Hydraulic Unloader Valve

(installed in Oil Pump

which is not shown)

Unloader Towers

3-Way Check

Valve

Loading...

Loading...