16

3-Way Check Valve – Provided on Hycomp model

compressors when two unloader valves are used.

This is a three-way check valve, used to prevent

the unloader control that is not currently unloading

the compressor from bleeding unload pressure to

atmosphere. The check valve is marked “inlet” and

“outlet”. Connect the “inlet” ports to the two unloader

valves, and connect the “outlet” port to the unloader

towers.

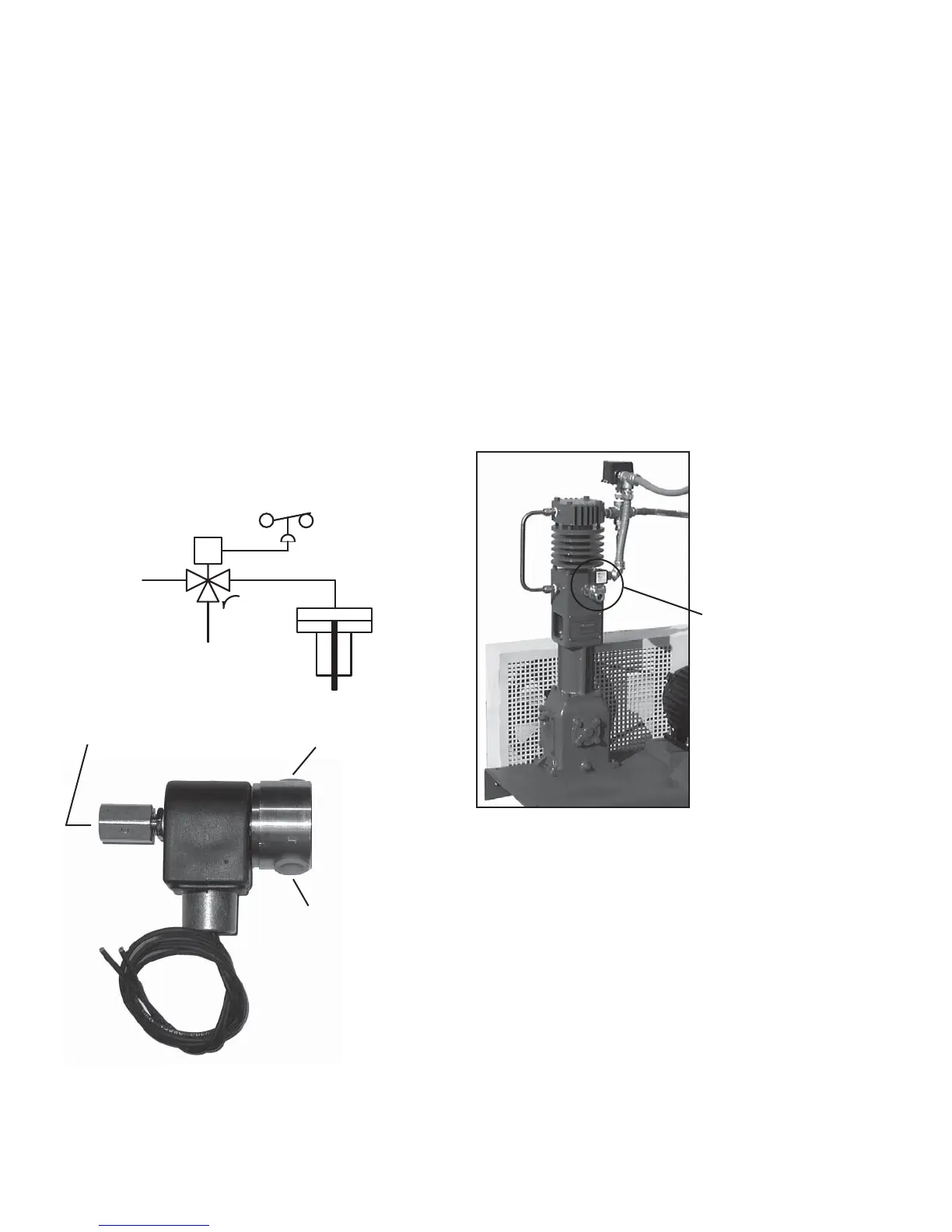

Three-Way Unloader Control Solenoid Valve

– Provided on air boosters and gas compressors with

suction valve unloading (Figure 11). The three way

unloader control solenoid receives an electrical signal

from a pressure switch to engage or release (load

or unload the compressor). The valve is designed

so that if electrical power is lost or the solenoid fails,

the valve will unload the compressor. There are

three gas ports on the unloader valve, as well as an

electrical connection. Port # 1 is the vent port. Port

# 2 is connected to the Unloader Towers or 3-Way

S

NO

PS

To Unloader

Pressure

Source

Vent (to atmosphere

or Compressor Inlet)

#3

#1

#2

Unloader

Tower

Figure 11: Three Way Unloader

Solenoid Valve Plumbing

Port #3 - to Unloader

Pressure Source

Port #1 - to vent

Port #2 -

to Towers

Check Valve. Port #3 is connected to the unloader

pressure source. If the port confi guration is different

than that listed above, it will be noted on the Piping

and Instrumentation Diagram.

If the unloader gas is air or a non-contaminating gas,

the solenoid can vent (Port #1) the gas to atmosphere.

If the unloading gas is a contaminating gas that cannot

be vented to atmosphere, then the solenoid must vent

this gas to the booster compressor suction line, or a

safe location. If this valve is part of a factory assembled

controls system, this port will be pre-plumbed or

tagged with piping instructions.

Port # 2 must be plumbed to the unloader towers or

three-way Check valve if a hydraulic unloader is also

used. If included as part of a Hycomp controls package,

the unloader valve (Port #2) is already plumbed.

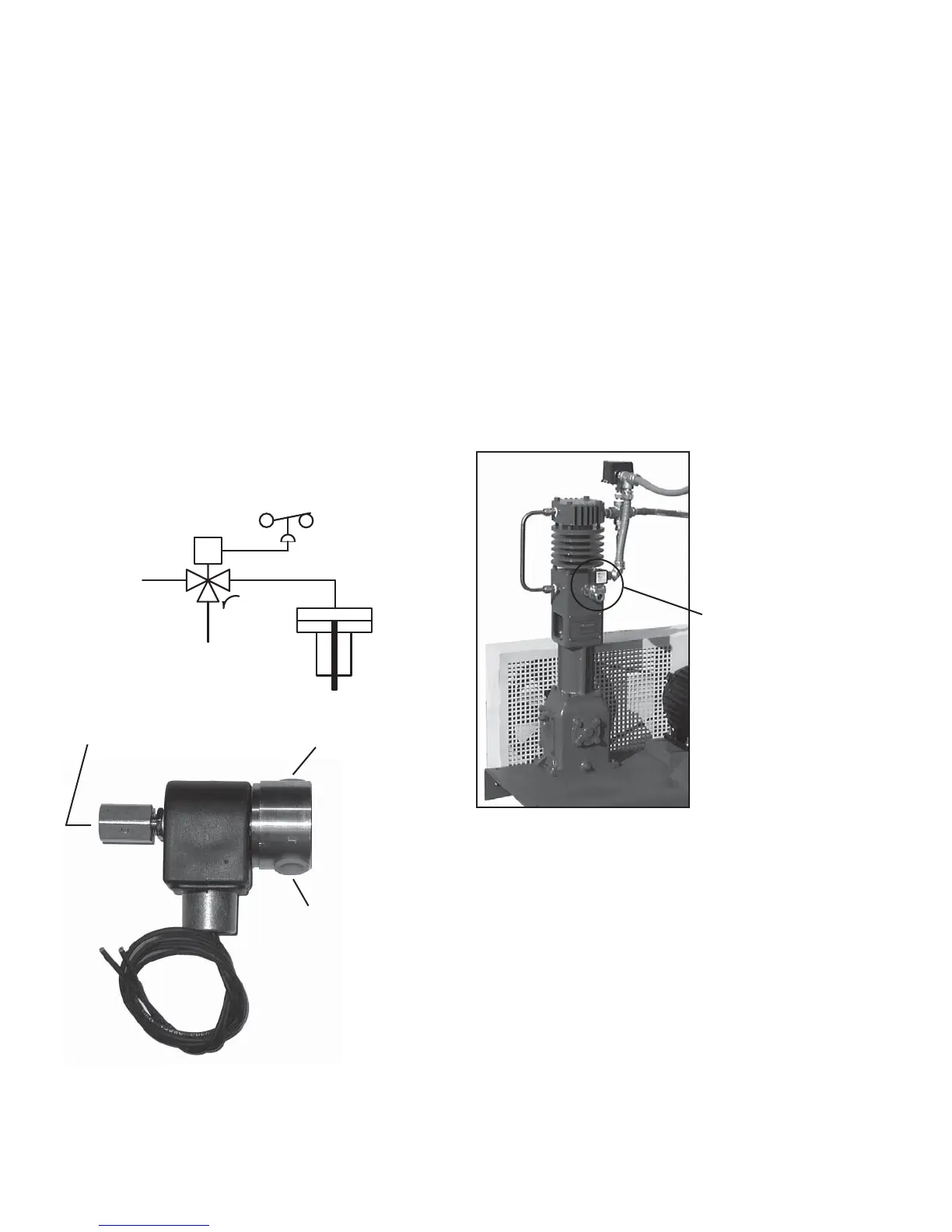

Inlet Shutoff

Solenoid Valve,

wired and plumbed

to compressor,

requiring plumbing

to inlet gas piping

Port #3 must be connected to the gas source that

provides pressure for unloading. Use a minimum 3/8”

line to connect this port to the pressure source. If part

of a Hycomp controls package, this port may already be

plumbed to a ‘Tee’ connected to the discharge pressure

switch, so only one line needs to be brought back to

the unloader valve/pressure switch.

The Three-Way Unloading Solenoid Valve requires

an electrical signal (check the side of the solenoid for

the voltage requirement - usually either 120 VAC or

24 VDC) to operate. When power is applied to the

solenoid, it will cause the compressor to load. When

Figure 12: Inlet Shutoff Solenoid Valve

Unloading

Loading...

Loading...