30

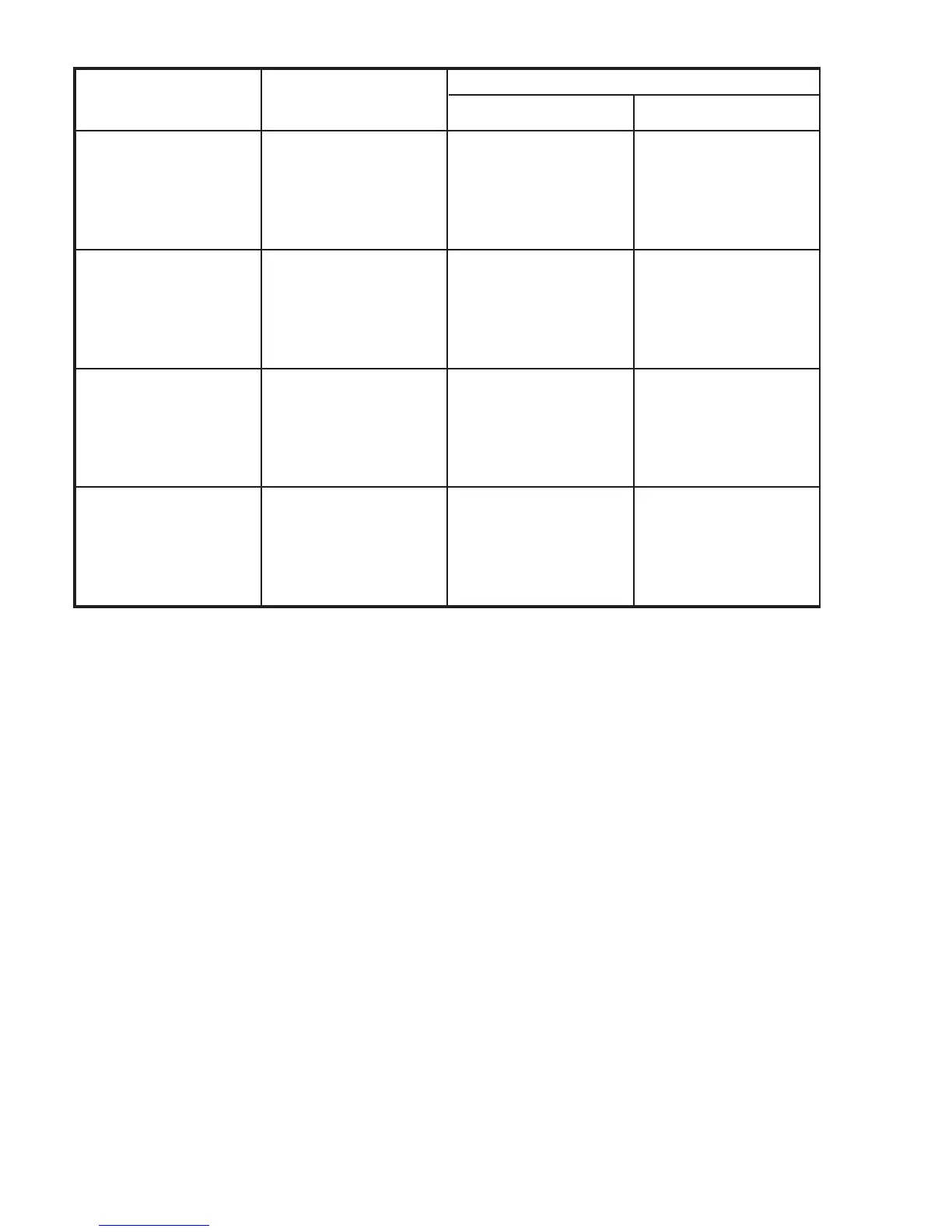

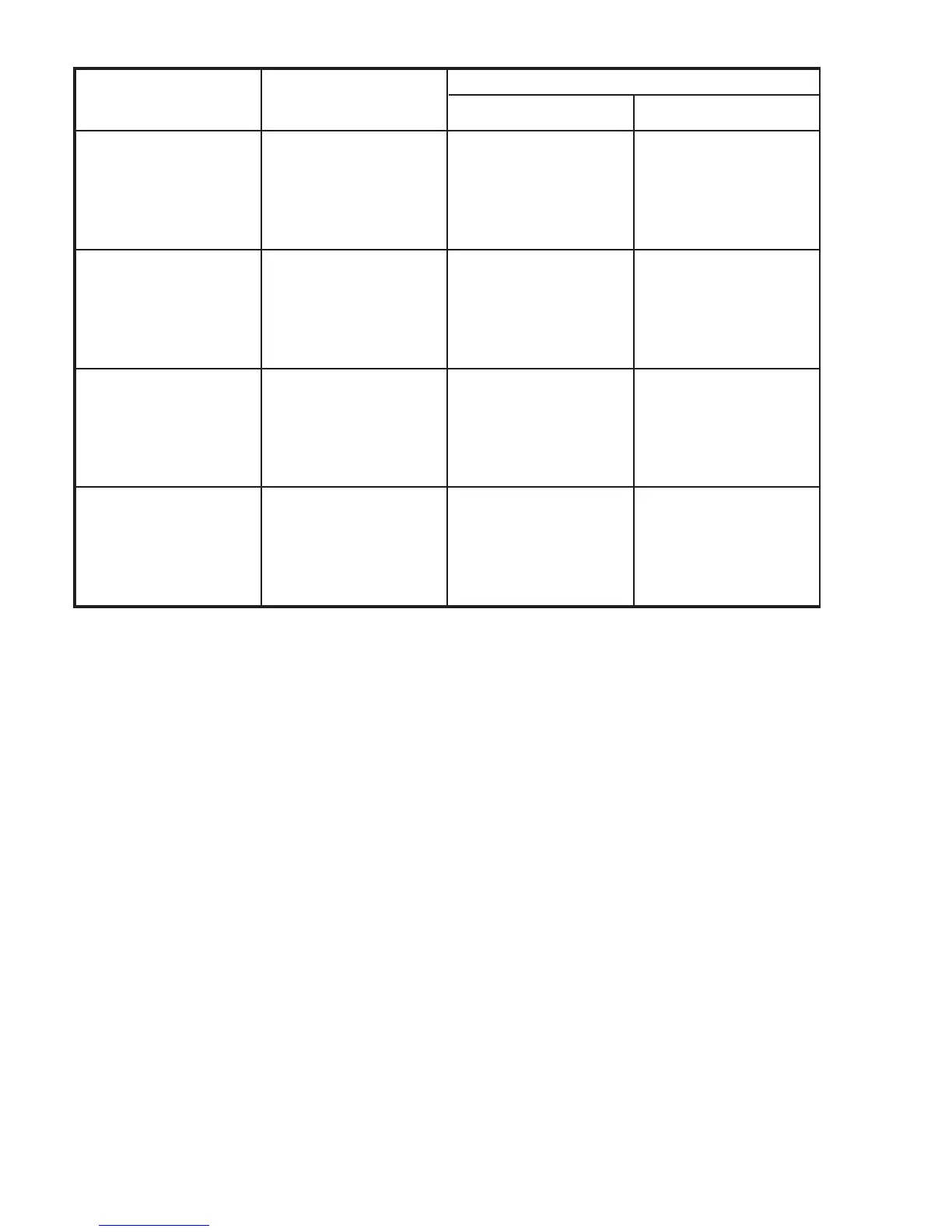

Table 5: Typical ‘V’ Belt Defl ection Forces Table

ADJUSTMENT OF MANUAL

UNLOADER CONTROLS

Hydraulic Unloading - All pressure lubricated Hycomp

model air compressors come with hydraulic unloading,

also known as load-less start. The hydraulic unloader

valve senses the oil pressure developed in the oil

pump, and allows air from the receiver to fl ow to the

unloader towers when the oil pressure is too low. When

the oil pressure has increased to an acceptable level,

the oil pressure closes a piston/spring mechanism,

closing off the receiver air pressure, allowing the

unloader towers to depressurize and thereby loading

the compressor.

The hydraulic unloader valve may be plumbed at the

factory. If not, see the Compressor Installation section

in this manual for details on how to plumb the unloader

control.

Two hydraulic unloader valves are available for

different receiver pressure ranges:

1RX001-3 Receiver pressure 0-200 psig

1RX001-4 Receiver pressure 200-500 psig

The proper hydraulic unloader valve must be used for

the operating requirements. No other adjustment of

the hydraulic unloader is possible.

Constant Speed Unloading (Dual Control if Used in

Conjunction with Hyrdaulic Unloader) - All pressure

lubricated Hycomp model ambient air compressors

can be set-up for constant speed unloading. When

used in conjunction with a hyrdraulic unloader valve,

this allows protection from low oil pressure damage,

as well as allowing the compressor to run continuously

with varying air demands. If the compressor starts/

stops more than six (6) times per hour, this is the

preferred control. Air pressure from the receiver is

split between the hydraulic unloader (described above)

and the constant speed unloader. The constant speed

unloader senses this receiver air pressure, and when it

rises above the user adjusted level, the constant speed

unloader allows air pressure to travel to the three-way

check valve, and then to the unloader towers, opening

the inlet valves. When the receiver air pressure drops

below a specifi ed level, the constant speed unloader

shuts off air fl ow to the unloader towers, vents the

remaining air pressure, and allows the unloader towers

to depressurize, loading the compressor.

‘V’ Belt

Cross Section

Small Sheave

Diameter Range (in)

Recommended Defl ection Force (lbs)

MIN. MAX.

4.6 10.2 14.8

5.0 - 5.2 11.6 17

2B 5.4 - 5.6 12.4 18.2

6.0 - 6.8 14.2 20

7.4 - 9.4 16.2 24

4.6 15.3 22.2

5.0 - 5.2 17.4 25.5

3B 5.4 - 5.6 18.6 27.3

6.0 - 6.8 21.3 30

7.4 - 9.4 24.3 36

4.6 20.4 29.6

5.0 - 5.2 23.2 34

4B 5.4 - 5.6 24.8 36.4

6.0 - 6.8 28.4 40

7.4 - 9.4 32.4 48

7.0 36.4 52

7.5 38.8 56

4C 8.0 - 8.5 44 64

9.0 - 10.5 48 72

11.0 - 16.0 56 84

Loading...

Loading...