29

Plunger with

Defl ection force

scale (lbs)

Small “O”-ring

Body with Defl ection

Scale (inches)

Large

“O”-ring

Figure 19d: ‘V’ Belt Tension Gauge

edge not in contact with the motor sheave. Observe

alignment of the face of the motor sheave with the line

of the straight edge. Adjustment of the motor and/or

mounting base will be required to correct angular

alignment.

Parallel Alignment: Place a straight edge across the

compressor fl ywheel with the loose end of the straight

edge not in contact with the motor sheave. Place a

straight edge across the compressor fl ywheel with

the loose end of the straight edge not in contact with

the motor sheave. Measure from straight edge to a

marked reference point on the belt at the fl ywheel.

Rotate belt to shift the marked reference point at the

motor sheave. Adjust sheave on motor shaft to obtain

equal measurements.

The belt can now be tightened via the motor base,

refer to specifi c V-belt manufacturer tension ratings.

An example of defl ection force tensioning follows:

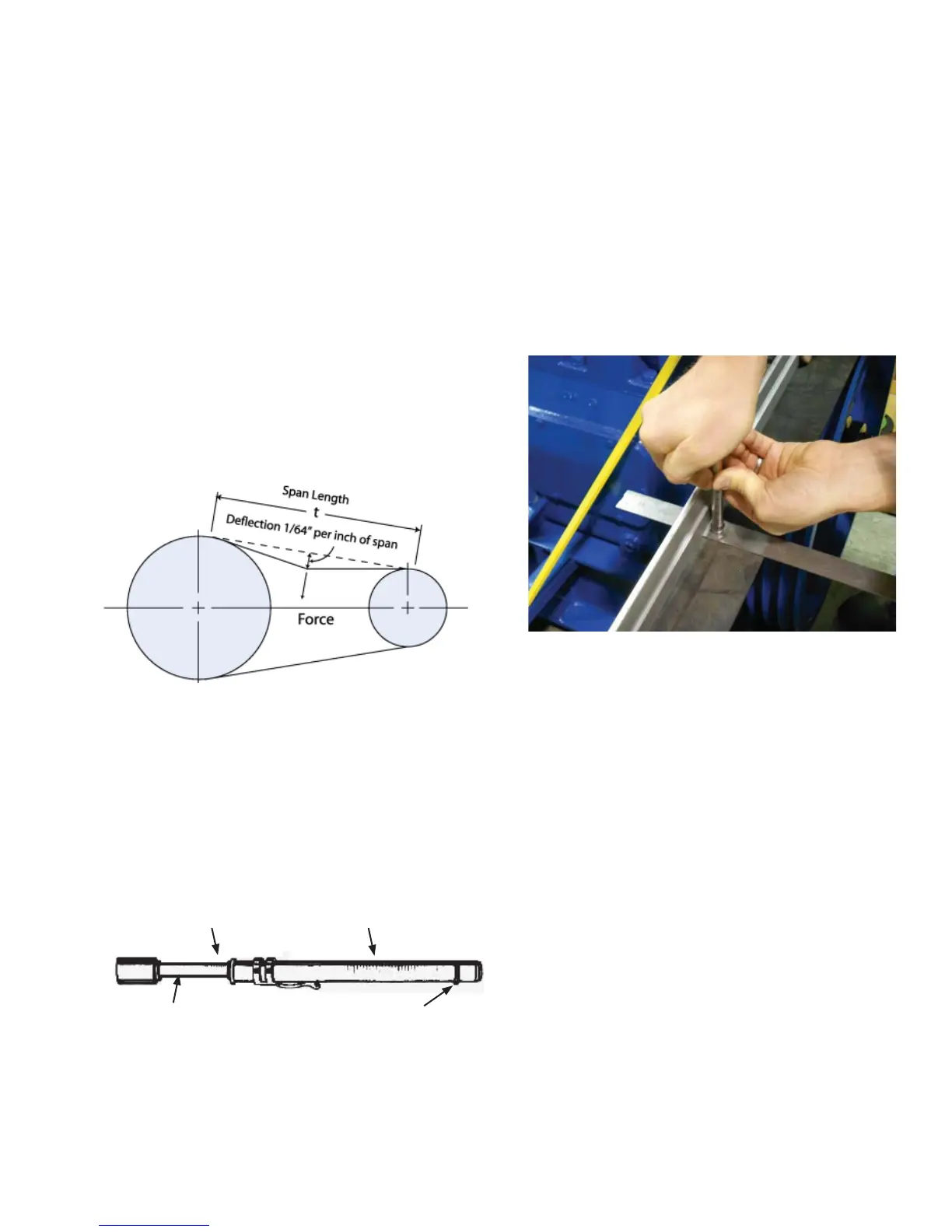

Measure span length (t). See fi gure 19c.

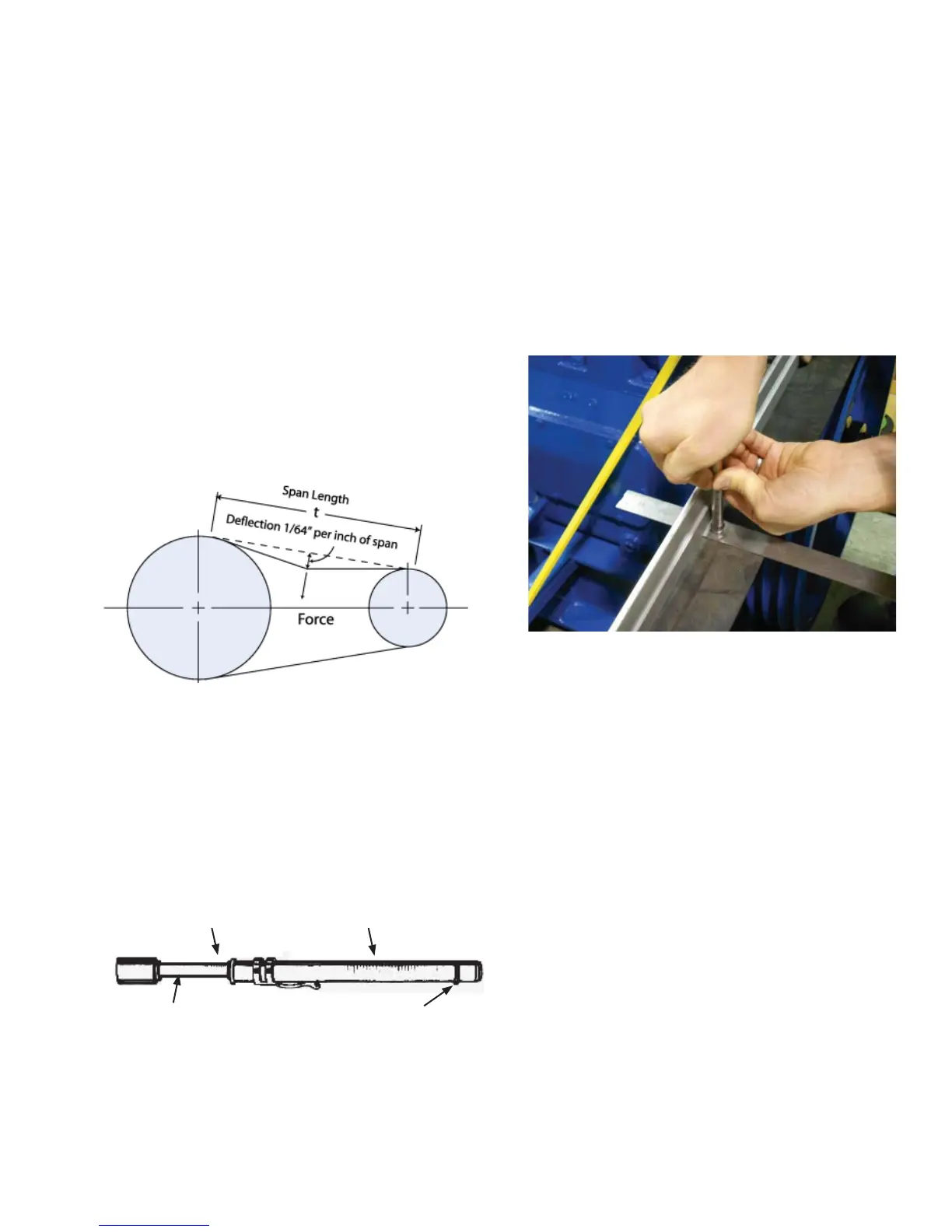

At the center of the span (t), apply force using the

tension tester perpendicular to the span. For banded

belts, place a piece of steel or angle iron across the

band width and defl ect the entire width of the band

evenly.

Use the straight edge placed across the sheave and

fl ywheel above the belt to establish a reference line.

Defl ect the belt until the bottom edge of the lower o-ring

is at the correct defl ection distance. Find the defl ection

force on the upper scale of the tension tester. The

sliding rubber O-ring will move up the scale as the

tester is compressed. See fi gure 19e.

Figure 19c: ‘V’-Belt Defl ection Measurement

Figure 19e: Tension Gauge Example

Compare the defl ection force with the range of forces

recommended (see table 4). If less than minimum the

belt should be tightened. Note: There normally will be

a rapid drop in tension during the run in period and the

belt must be inspected periodically to ensure the belt

tension is within the specifi ed range.

For example if you have a 4B belt with a motor sheave

of 5.4” diameter and a span of 32”, you would defl ect

the belt 32/64” (1/2”) from the reference line. At

that amount of defl ection the force applied should

be 36.4 lbs. max. With new belts, start near the

maximum defl ection force value and check the tension

periodically during the fi rst 24 to 48 hours of service

duty. You must adjust to run in the range of 24.8 lbs.

to 36.4 lbs. See Table 5.

Care should be taken during tension adjustments to

assure that the alignment is maintained.

Upon completion of alignment and tension adjustment,

all mounting hardware should be re-checked for proper

tightness.

Use an appropriate sized V-belt tension gauge, on

the scale reading “Defl ection Inches”, set the O-ring

to show a defl ection of 1/64” per inch of span length

(t). For example a span length of 32” will require a

defl ection of 32/64” or 1/2”.

Loading...

Loading...