41

* OIL AND FILTER SHOULD BE CHANGED EVERY 2,000 HOURS OR 6 MONTHS, WHICHEVER OCCURS

FIRST. UNITS WITHOUT AN OIL FILTER SHOULD BE CHANGED EVERY 1,000 HOURS OR 6 MONTHS,

WHICHEVER OCCURS FIRST.

** HUMID CLIMATES AND CERTAIN OPERATING CONDITIONS CAN CAUSE MOISTURE TO BE DRAWN

INTO THE MOTOR. THE MOTOR SHOULD BE RUN ON A CLEAR DAY WITHOUT THE V-BELTS FOR AT

LEAST AN HOUR. DURING THIS TIME THE MOTOR SHOULD HEAT UP ENOUGH TO VAPORIZE THE

MOISTURE WITHIN THE MOTOR.

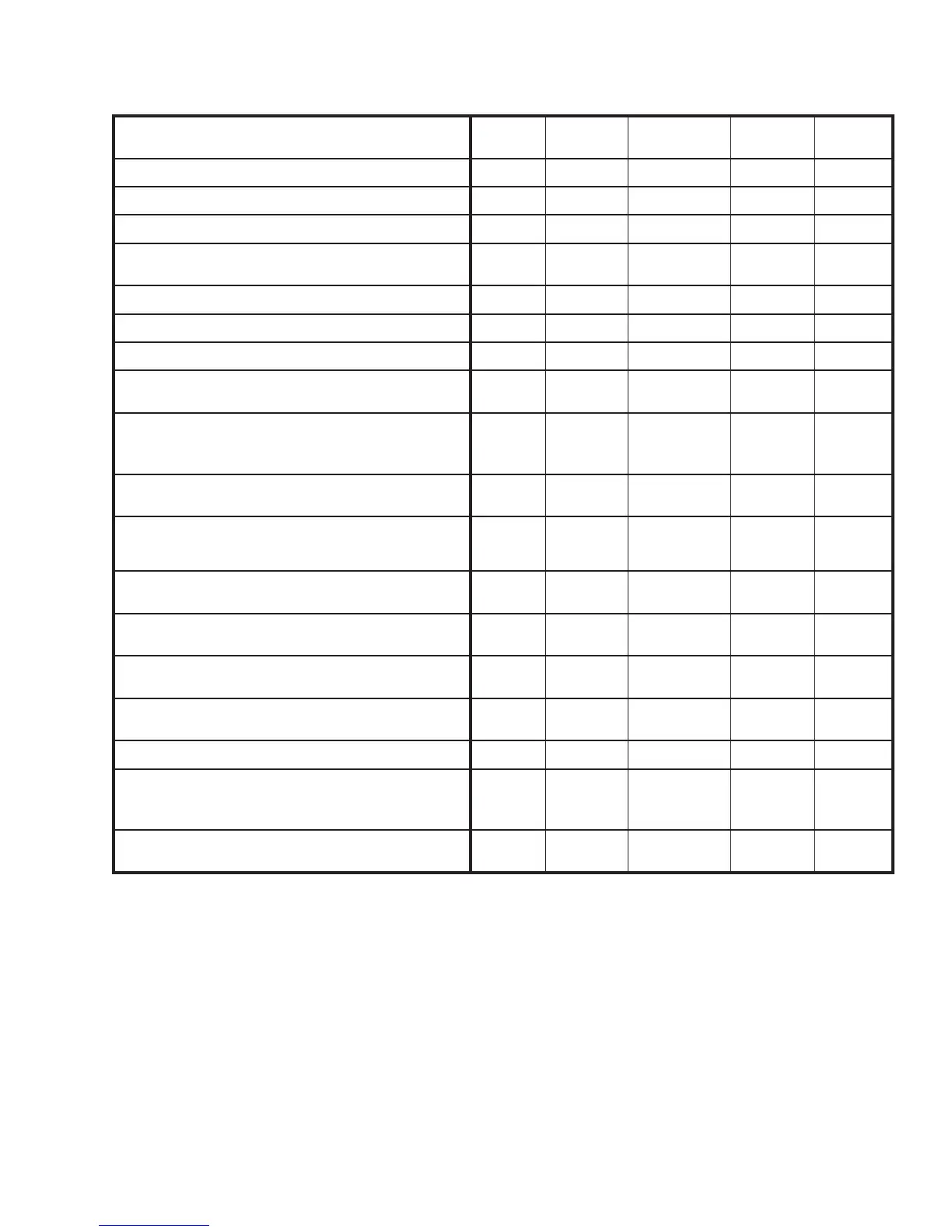

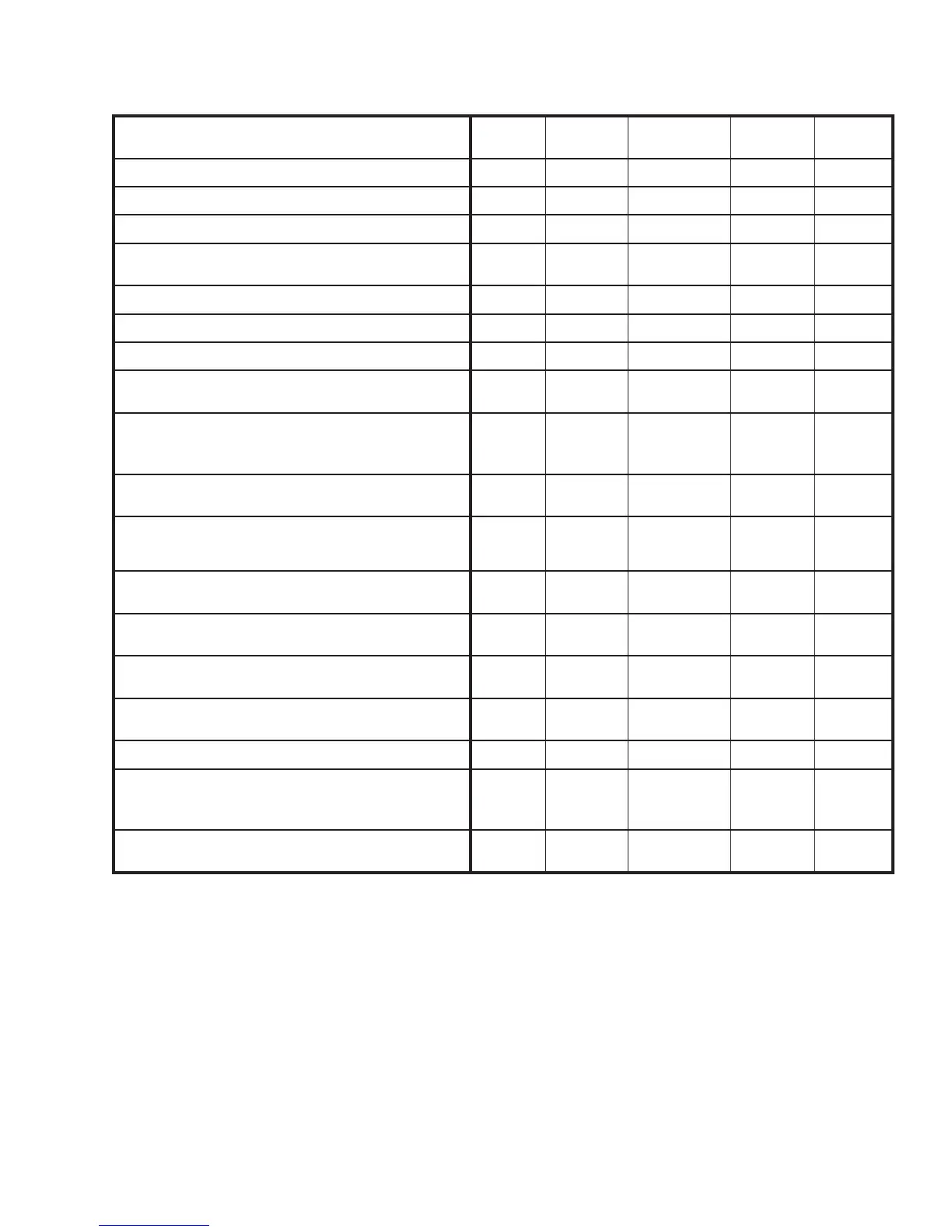

Table 7: Maintenance Schedule

DAILY WEEKLY MONTHLY

6

MONTHS YEARLY

VISUALLY CHECK THE COMPRESSOR X

CHECK OIL PRESSURE X

CHECK DISCHARGE PRESSURE X

DRAIN THE CONDENSATE FROM PIPING

SYSTEM, DRAIN LEGS AND AIR RECEIVER

X

CHECK FOR OIL IN DISTANCE PIECE X

CHECK THE CRANKCASE OIL LEVEL X

CHECK FOR LEAKS IN THE PIPING SYSTEM X

MANUALLY OPERATE ALL SAFETY VALVES X

CLEAN CYLINDER, INTERCOOLER AND

AFTERCOOLER COOLING SURFACES

X

CHECK ‘V’ BELT TENSION X

REPLACE INTAKE FILTER ELEMENT X

CHANGE OIL AND OIL FILTER * X

INSPECT VALVES, REPLACE GASKETS ON

REASSEMBLY

X

INSPECT UNLOADER DIAPHRAGMS/PISTONS X

INSPECT ALL CONTROL SWITCHES X

INSPECT MOTOR STARTER CONTACTS X

LUBRICATE MOTOR BEARINGS IN ACCOR-

DANCE WITH MANUFACTURER’S RECOM-

MENDATIONS**

X

REPLACE RINGS, VALVES, PACKINGS (not on

Ambient Air Compressors), OIL SCRAPERS

X

Loading...

Loading...