43

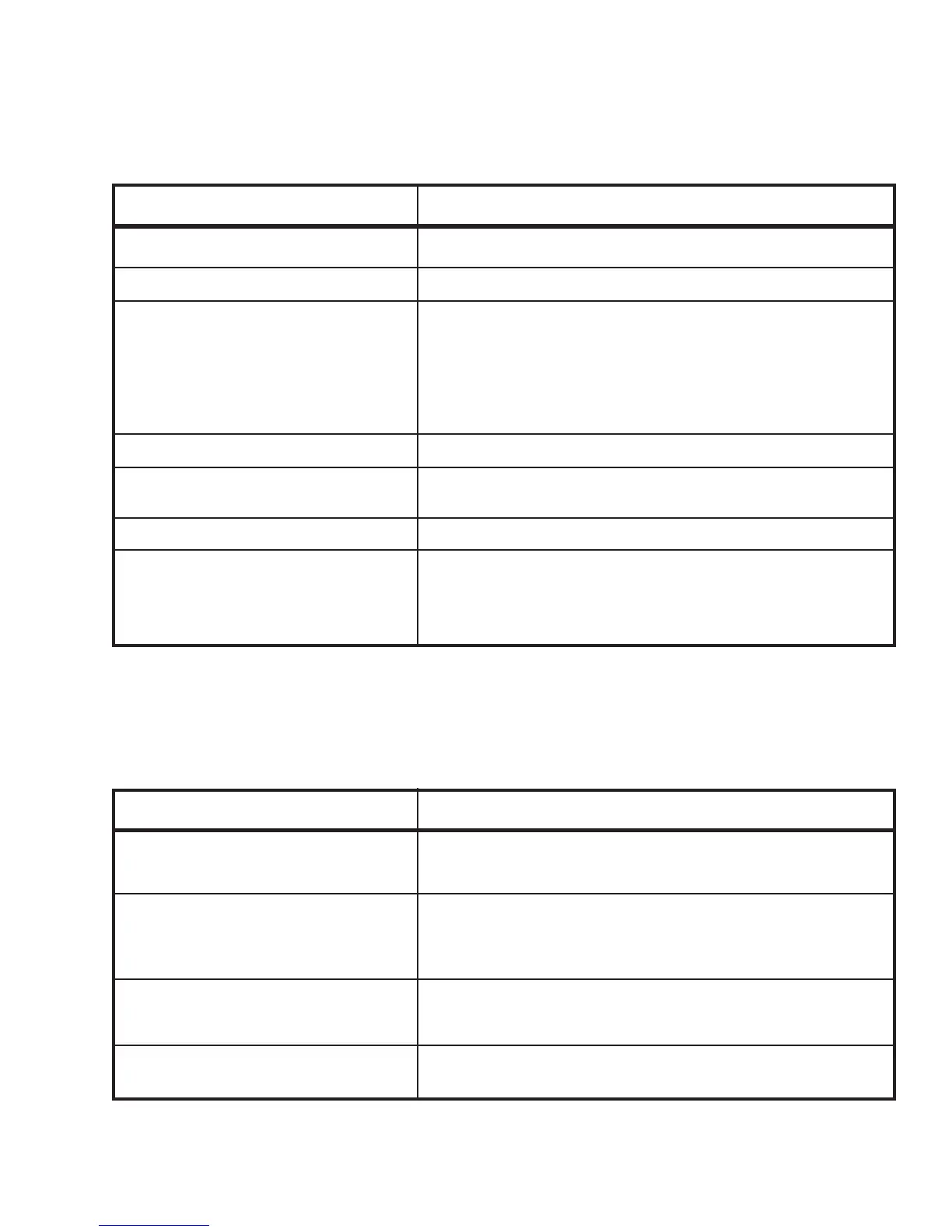

LOW OIL LEVEL

CLOGGED OIL STRAINER

DEFECTIVE OIL PRESSURE

REGULATING VALVE

WORN OUT OIL PUMP

OIL PUMP SUCKING AIR DUE TO GASKET

FAILURE

DEFECTIVE OIL PRESSURE GAUGE

INCORRECT FLYWHEEL ROTATION

FILL CRANKCASE TO FULL MARK.

REMOVE AND CLEAN OIL STRAINER.

‘B’, ‘C’, ‘D’, ‘E’ AND ‘V’ BLOCKS: REMOVE REGULATING VALVE

ADJUSTING SCREW, SPRING AND BALL. CHECK FOR WEAK OR

BROKEN SPRING OR DAMAGED SEAT. REPLACE OR REPAIR AS

NECESSARY.

‘F’ BLOCK: REMOVE OIL PUMP AND INSPECT REGULATING VALVE

PLATE, SPRING, AND SEAT. REPLACE OR REPAIR DAMAGED PARTS

AS NECESSARY.

REPLACE OIL PUMP.

CHECK GASKET OR SEAL IN OIL PICKUP LINE. REPLACE AS

NECESSARY.

CHECK GAUGE AND REPLACE AS NECESSARY.

CHECK THAT THE FLYWHEEL FAN IS CLOCKWISE WHEN VIEWED

FROM THE OIL PUMP END, IF NOT, CHECK WITH A COMPETENT

ELECTRICIAN TO SEE IF THE MOTOR ROTATION CAN BE CHANGED

BY RECONNECTING THE MOTOR LEADS.

TOUBLESHOOTING CHART (cont’d)

LOW OR NO OIL PRESSURE

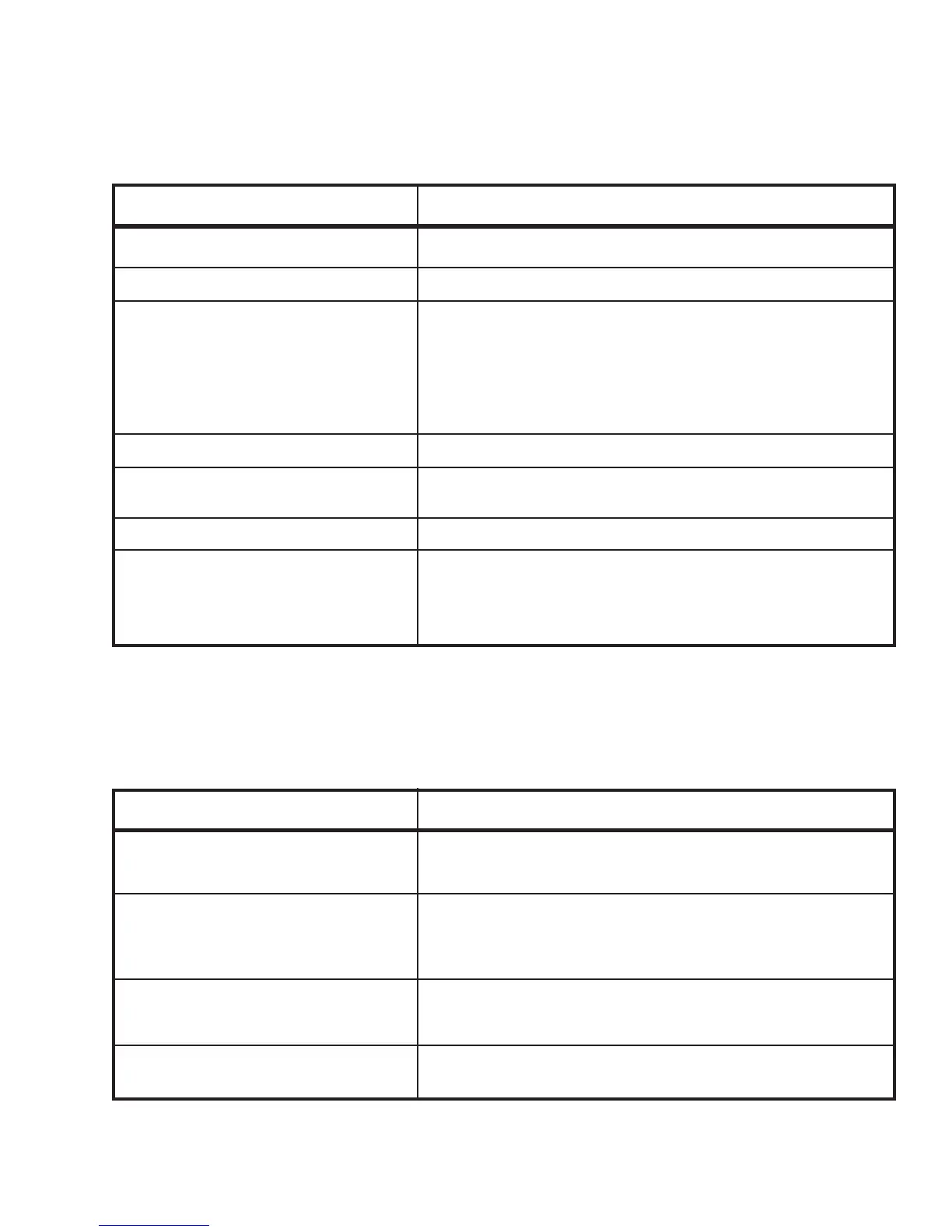

DIRTY COOLING SURFACES

INADEQUATE VENTILATION

LEAKING SECOND STAGE VALVES

CAUSING HIGH FIRST STAGE AIR

PRESSURES

RESTRICTION IN AIR LINES

CLEAN THE COOLING SURFACES OF THE CYLINDER HEAD,

CYLINDERS, INTERCOOLER AND AFTER COOLER INCLUDING ANY

WATER PASSAGEWAYS.

RELOCATE THE COMPRESSOR TO A MORE SUITABLE AREA

HAVING CLEAN, DRY, COOL AIR WITH GOOD VENTILATION. AIR

COOLED COMPRESSORS SHOULD NOT BE LOCATED IN HOT OR

HIGH HUMIDITY AREAS.

CHECK FOR LEAKING VALVES OR VALVE GASKETS ON SECOND

STAGE. CORRECT AS NECESSARY.

CHECK DISCHARGE PIPING AND INTERCOOLER FOR DAMAGE TO

LINES CAUSING RESTRICTION IN AIR FLOW.

OVERHEATING

PROBABLE CAUSE

SUGGESTED REMEDY

PROBABLE CAUSE

SUGGESTED REMEDY

Loading...

Loading...