20

a vent line to allow gas to escape to the atmosphere.

Review all federal, local and fi re codes to ensure

that venting is a safe option. For instance, venting

nitrogen to the local atmosphere can be dangerous

in small enclosed areas as asphyxiation can occur.

Contact local OSHA representatives for assistance in

determining safety requirements for different gases.

Purging - It may be necessary to purge the packings

with an inert gas like nitrogen. Purging requires a loop,

whereby the purge gas, at pressure, can be routed to

a safe location for disposal of the mix of purge and

process gases.

Padding - A pad gas like nitrogen can be used to

pressurize the packings at a pressure higher than

the suction pressure of the booster compressor. Any

leakage of the pad gas will enter the process gas

stream contaminating the gas stream. However, the

pad gas will prevent the process gas from leaking to

atmosphere. This is often done in situations where

very tight gas control is required. As the pad gas may

leak to local atmosphere, precautions must be taken

to ensure it will not endanger personnel, property, or

equipment. Contact local OSHA representatives for

assistance in determining safety requirements for

different gases.

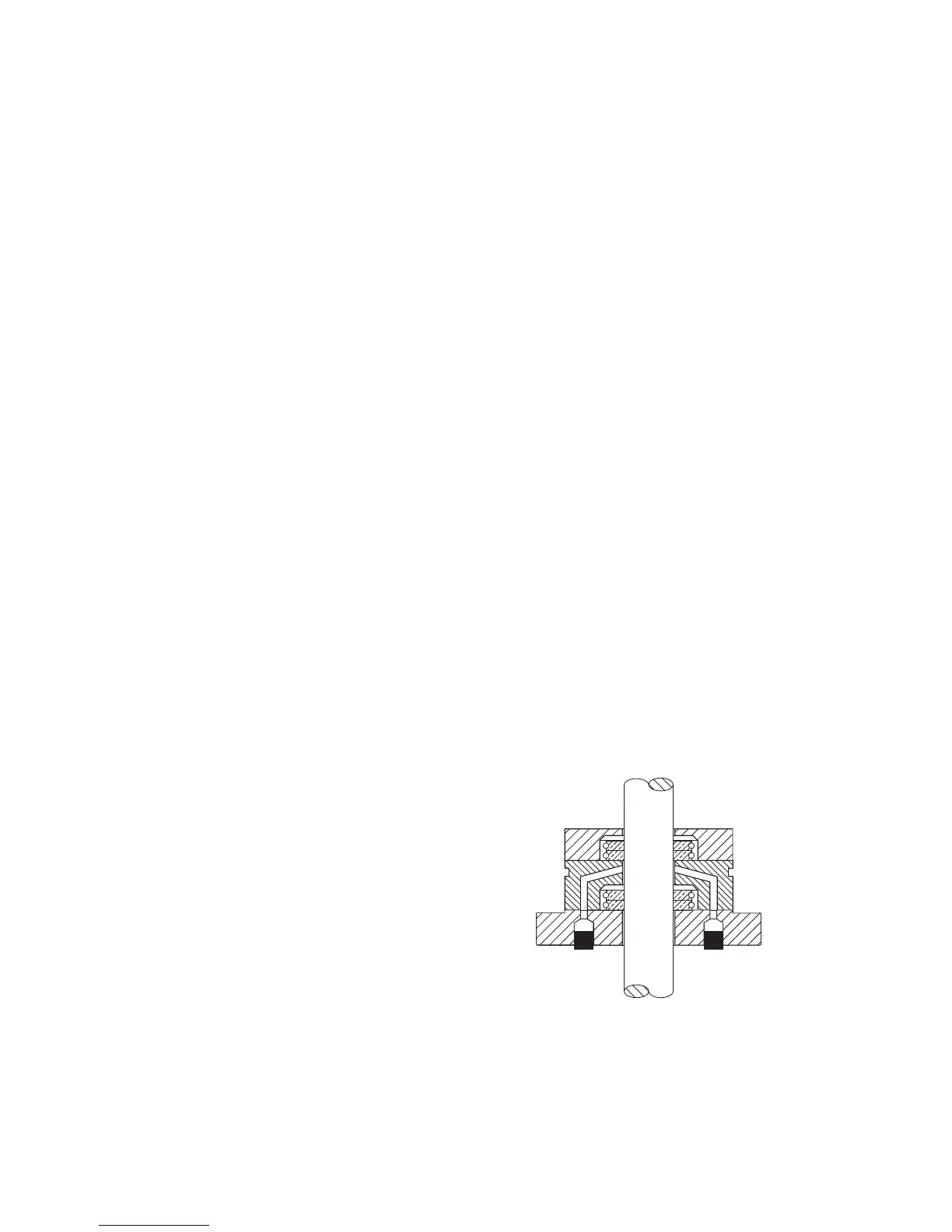

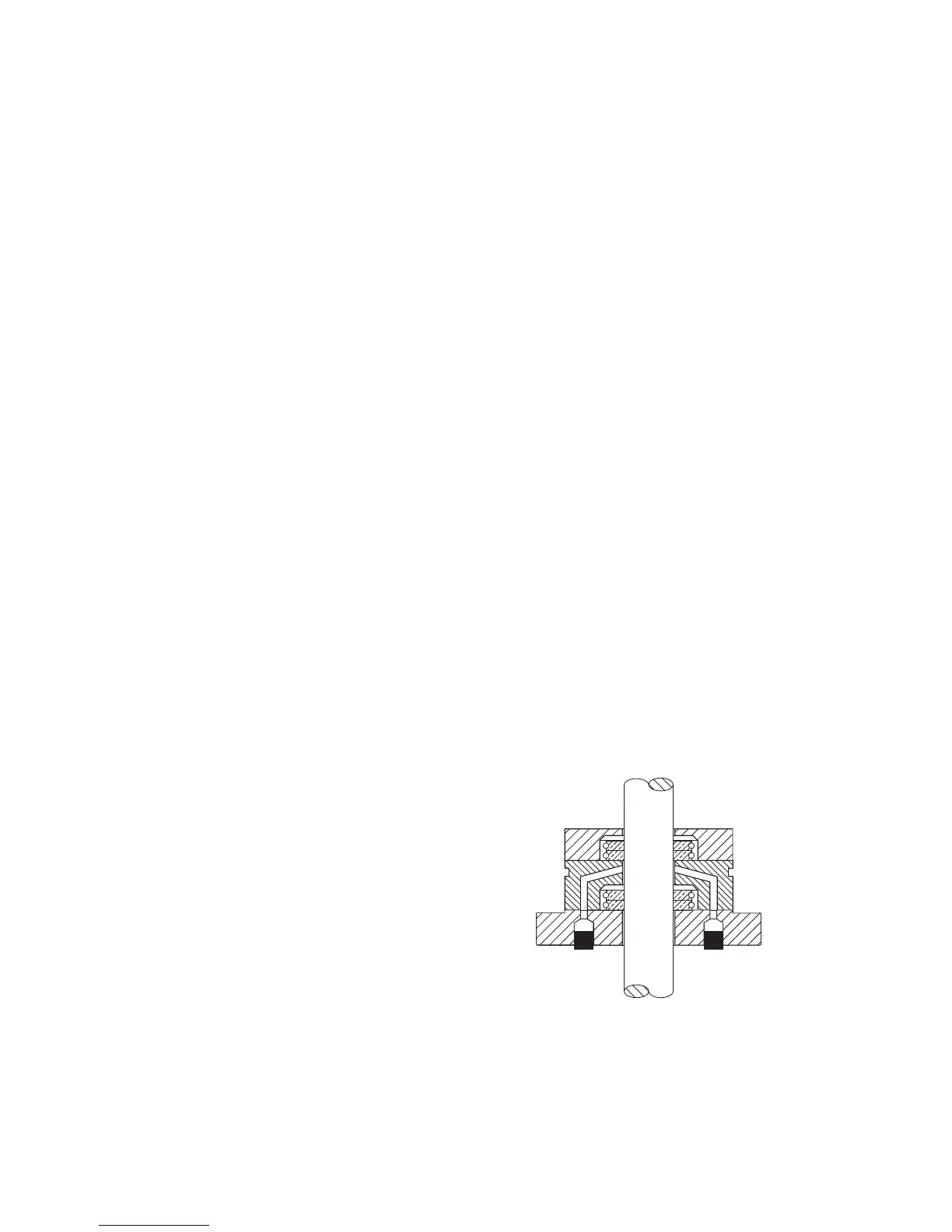

‘B’ SERIES BOOSTERS - The ‘B’ series booster

compressor is designed to compress air or

nonhazardous/non-contaminating gases, as follows

(see Figure 16):

B21 - Two pairs of tangent-tangent segmented

packings per rod, set for suction pressures above

ambient and below 100 psig.

B31 - Three pairs of tangent-tangent segmented

packings per rod, for inlet pressures of 100 psig to

165 psig.

B22 - Two pairs of tangent-tangent segmented

packings per rod, set for suction pressures at or below

ambient.

B32 - Three pairs of tangent-tangent segmented

packings per rod, set for suction pressures at or below

ambient, with tighter leakage control than the B22

arrangement.

Additional ‘B’ style packing arrangements can be

engineered for specialty applications. If your ‘B’ style

compressor does not match to the four listed above,

contact the factory for assistance.

The ‘B’ series of gas packings does not allow for a

vent or purge option. Therefore, there is no protection

if gas escapes past the packings -the gas releases

into the open crosshead piece, and will escape to the

surrounding atmosphere. This may be acceptable for

gases other than air, depending upon the location of the

compressor (indoor/outdoor), how well the compressor

is ventilated with fresh air, and the gas itself. Contact

your local OSHA representative and fi re marshall for

assistance in determining safety requirements for all

gases.

B21 Series:

No. of Packings per Rod: 2

Pressure side: Top

Vents: Plugged

Maximum Inlet Pressure: 99 psig

Minimum Inlet Pressure: 1 psig

Figure 16: Gas Packing Arrangements for ‘B’ Series Air Boosters and Gas Compressors

Loading...

Loading...