2120

7. OPTIONAL LOAD SPREADING BRIDGES

8. LEG ADJUSTMENT

ACTUAL PULL FORCE READ DIRECT FROM GAUGE

50mm dia Disc Area 1964mm

2

Actual Pull Force 75mm dia Disc Area 4418mm

2

Bond Strength kN Bond Strength

MPA Mpa

0.51 1.00 0.23

1.01 2.00 0.45

1.53 3.00 0.68

2.03 4.00 0.90

2.55 5.00 1.13

3.05 6.00 1.36

3.56 7.00 1.59

4.07 8.00 1.81

4.58 9.00 2.04

5.09 10.00 2.26

5.06 11.00 2.49

6.11 12.00 2.72

6.62 13.00 2.94

7.13 14.00 3.16

7.63 15.00 3.40

8.15 16.00 3.62

8.66 17.00 3.85

9.16 18.00 4.07

9.67 19.00 4.30

10.20 20.00 4.52

10.70 21.00 4.98

11.71 23.00 5.20

12.22 24.00 5.43

12.73 25.00 5.65

Mpa (Mega Pascales) = N/mm squared

Mpa = Actual Pull Force divided by Area of Disc x 1000

MATERIAL BOND TESTER KIT continued..

IMPORTANT! A low reading will be obtained if:

• The pull-off tester is misaligned and not perpendicular to the specimen

• The specimen is misaligned and not perpendicular to the pull-off tester

• The bondline is not of uniform thickness (0.5mm)

• A sudden or erratic loading is applied.

Note: This information is for guidance only. Please also refer to adhesive manufacturer’s

data and safety sheets.

Replacement discs available in both sizes from stock.

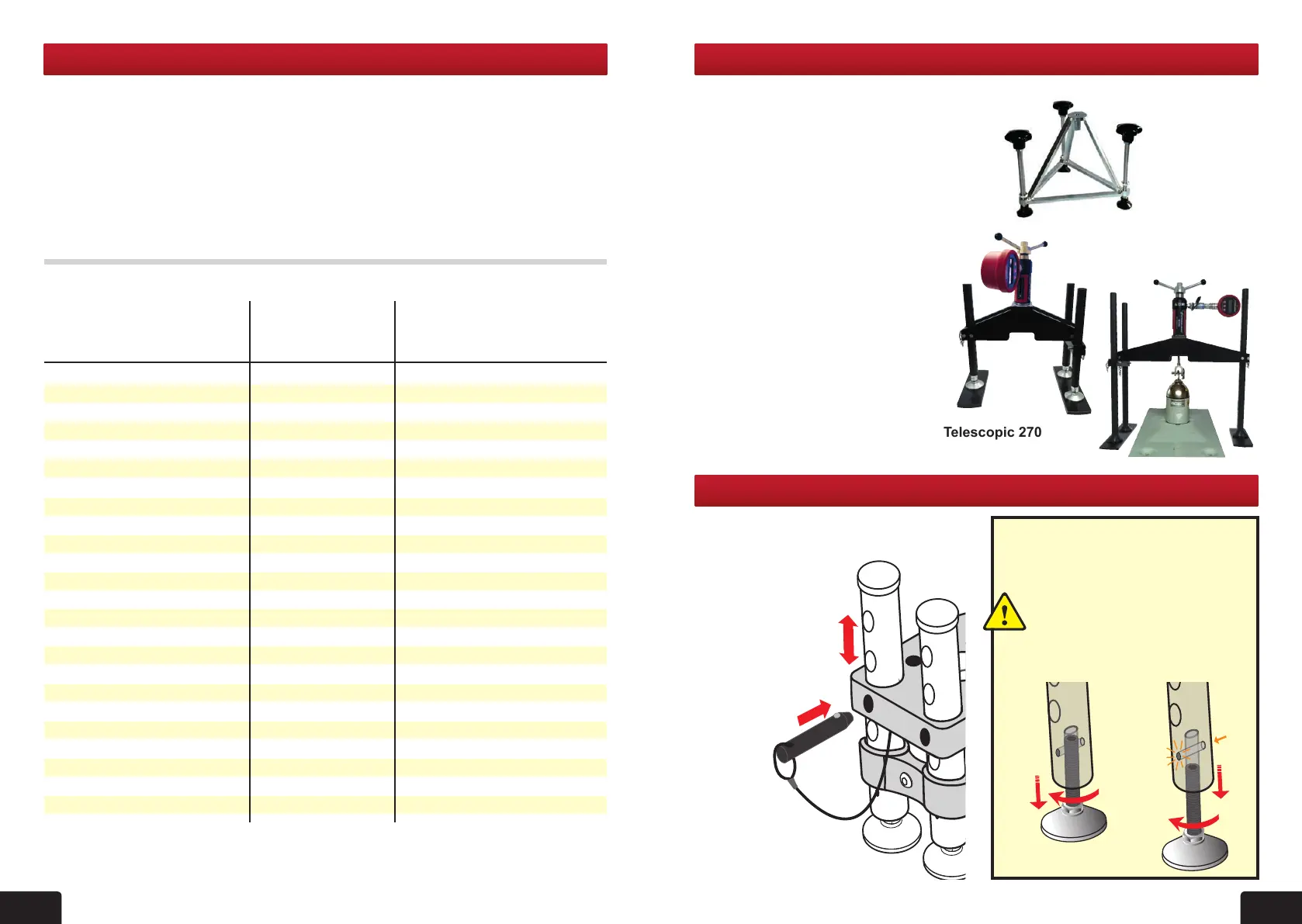

Pyramid Stool

Telescopic 270

Telescopic

600

Hydrajaws offer three optional load

spreading bridges, a pyramid stool with

threaded legs and a 270mm or 600mm

wider span bridge with telescopic legs.

These are designed to attach easily to

the Hydrajaws M2000 Tester.

To install, rst remove any existing load

spreading bridge by removing the two

positioning screws using the 3mm ball

driver. Use the same screws to secure

the tester to the optional bridge.

The 270mm and 600mm load

spreading bridges can be installed so

the tester is operated in two different

positions as illustrated. The legs are

fully adjustable to suit the testing

application.

A thread adaptor coupler is also

supplied to extend the accessory in

use. The Pyramid stool is supplied

with an extended bolt test adaptor.

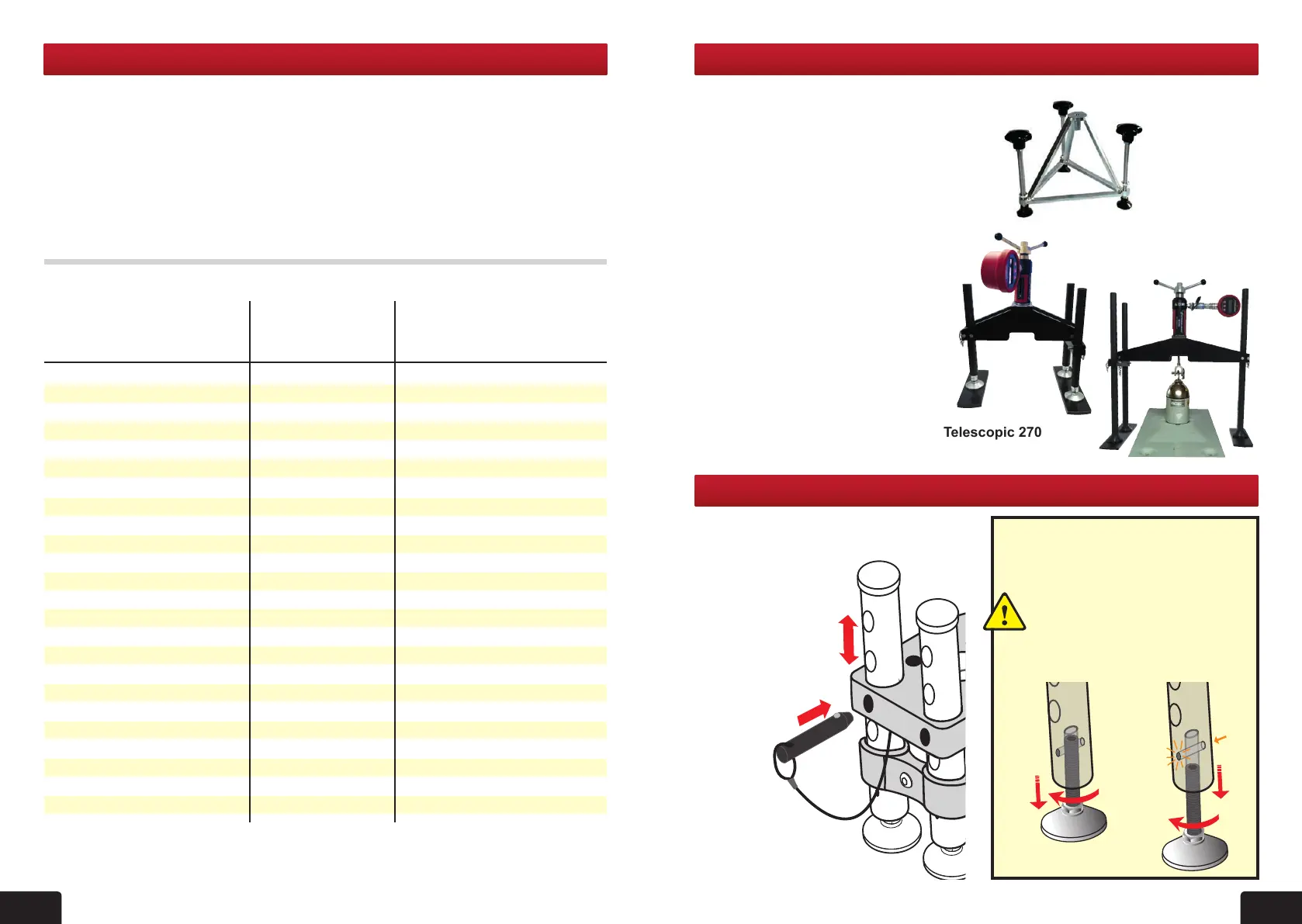

To adjust leg height:

- pull out pin.

- adjust leg to desired

height.

- line up hole and

insert pin until it clicks

into place.

Fine adjustment can be made by

unscrewing the feet by no more than

approximately 15mm.

Caution:

If light is visible through the bottom

indicator holes then the leg has

been unscrewed too far. Dont

expose more than 15mm of thread.

8

4

Loading...

Loading...