4 5

1. GENERAL TESTING PROCEDURE

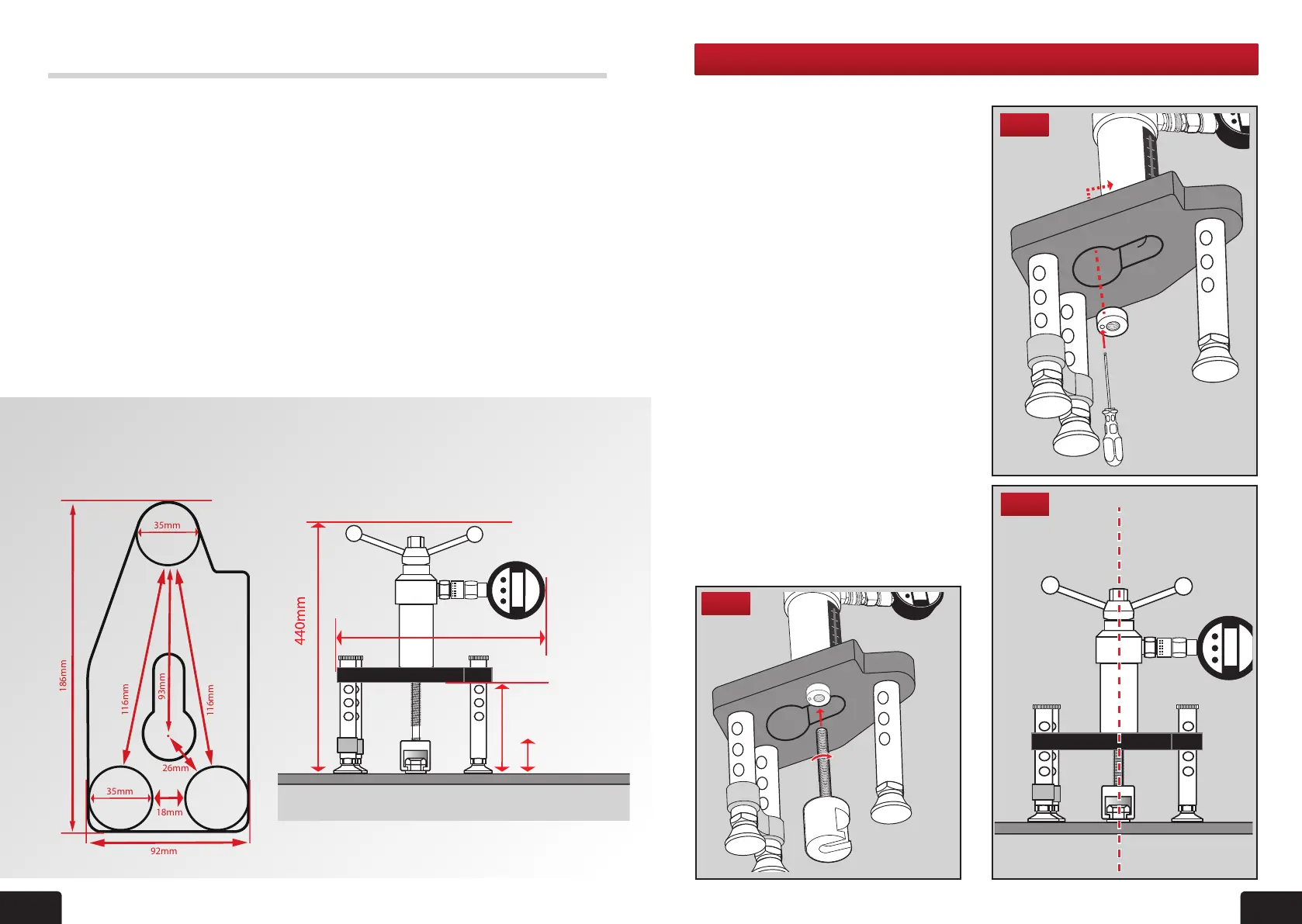

SETTING UP THE TESTER

1 Fit the appropriate adaptor to the tester.

Example shown is a bolt tester adaptor.

(For tting of other adaptors please see

individual instructions in this manual).

2. The tester is supplied with a locking

adaptor tted into the tester body.

This locking adaptor can be removed

for tting of different adaptors by using

the 3mm Ball Driver. When replacing

back in ensure it is fully engaged into

the tester body before tightening

(g 1). Thread the bolt tester adaptor

into this, until it is fully engaged, using

a quarter turn for position (g 2).

3. Make nal adjustments so that the bolt

tester adaptor, tester and xing are

aligned (g 3).

4. Position the tester so that the gauge

can be easily read.

5. Adjust the length of the telescopic legs

(see section 8) so that all three are in

contact with the base material and the

load spreading bridge is aligned and

level by referring to the bubble levels on

the bridge.

Fig 3

Fig 2

Fig 1

• Pull-out load range 0-25kN/lb/f

• Weight

Tester only 2.2kg

Packaged weight 8kg (will vary)

• Stroke scale 0-50mm

• Effective stroke 50mm

• Load gauge Interchangeable

• Casing Aluminium

• Loading jaw Pivotable through

360° with Spring

return

• Operating handle Standard size

with

integrated 22mm

operating nut for

conned spaces

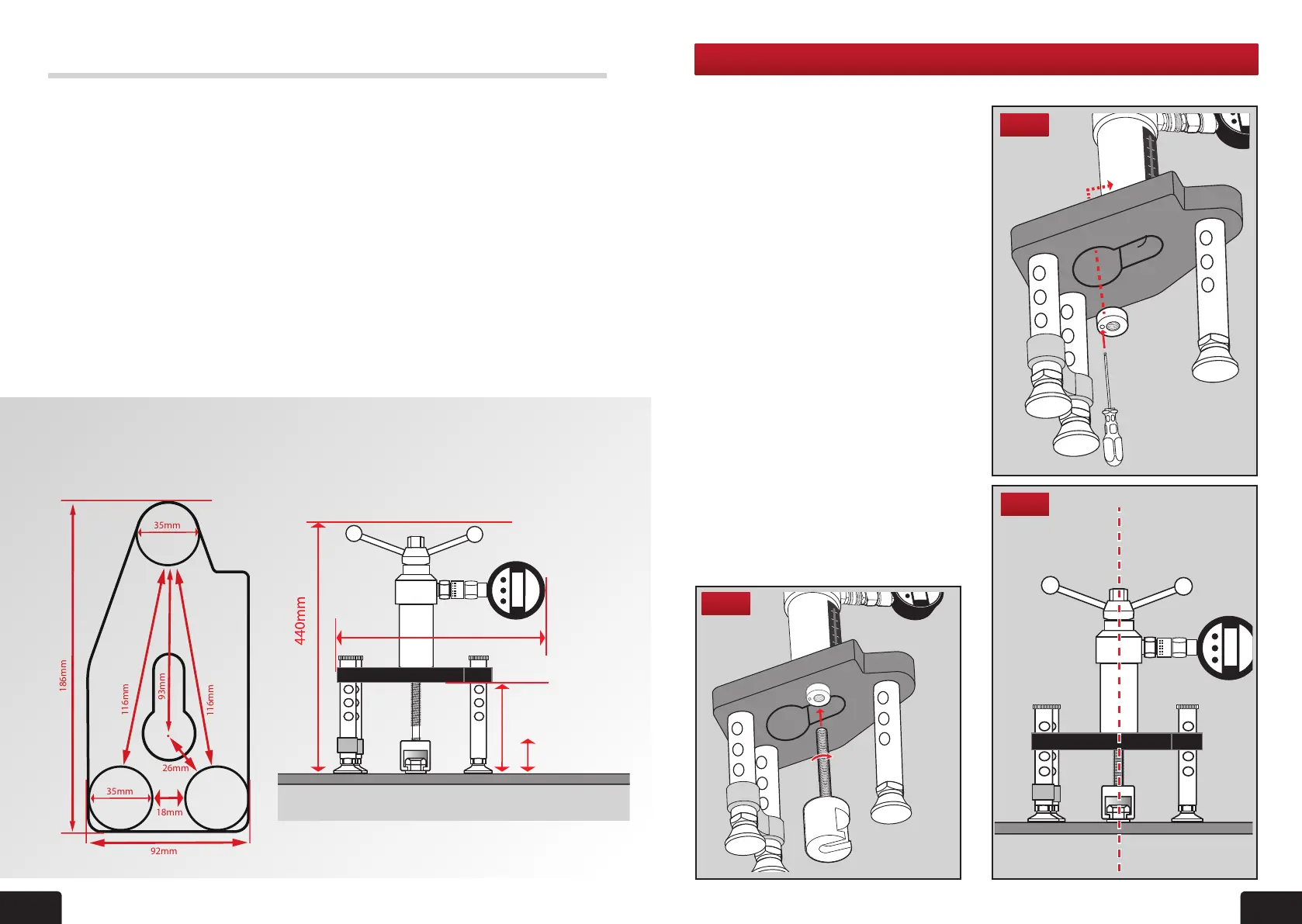

TECH SPECIFICATIONS

Bridge Footprint and Tester dimensions

Load Gauges

• Ranges available: Digital: 0-25kN

• Accuracy: Digital to +/-0.5% fsd

• Indication of pull-out load

• Calibrated in kN

• ALL gauges are dual scale. kN/lbf.

Digital gauges are supplied set to kN

and are easily switchable to lbf by

the user.

• Traceable UKAS calibration certicate

supplied with each gauge

• Protective rubber cover

• Impact resistant glass

• Protection against sudden load relief

(i.e. sudden failure of xing)

• Digital: peak hold memory

• Working Temperature:

Digital: -30°C to +85°C

M2000 Bridge Footprint M2000 Dimensions

4

350mm

182mm

Highest

93mm lowest

116mm

186mm

35mm

35mm

116mm

93mm

92mm

26mm

18mm

Loading...

Loading...