Repair 1800 SRM 1038

CLEAN

CAUTION

The bearing cones can be damaged if the cones

are dried by rotating with compressed air.

The parts, except the bearing cones, can be dried with

compressed air.

NOTE: Dry the parts immediately after the parts are

cleaned and washed.

Dry the parts with soft, clean paper or rags.

NOTE: Apply the fluid used in the brake housing to

the cleaned and the dried parts that are not damaged

and are to be assembled.

Apply a special material that prevents corrosion and

rust to all surfaces. If parts are to be stored, put the

parts in a special paper that prevents corrosion and

rust.

Ground and Polished Parts

WARNING

To prevent serious eye injury, always wear safe

eye protection when doing maintenance or ser-

vice.

If you use cleaning solvents, hot solution tanks,

or alkaline solutions incorrectly, serious per-

sonal injury can occur. To prevent serious

personal injury, follow the instructions sup-

plied by the manufacturer of these products.

Do NOT use gasoline to clean parts. Gasoline

can explode and cause serious personal injury.

CAUTION

Use only solvent cleaners to clean ground or

polished metal parts. Hot solution tanks or wa-

ter and alkaline solutions will damage these

parts. Isopropyl alcohol, kerosene, or diesel

fuel can be used for this purpose.

1. Use solvent cleaner to clean surfaces.

2. If necessary, remove gasket material from parts.

Parts With Rough Finish

NOTE: Do not clean friction discs. Wipe off each disc

with a clean rag before applying brake cooling fluid

to their surfaces during assembly.

Parts must remain in hot solution tanks until com-

pletely cleaned and heated.

1. Clean with cleaning solvent or in a hot solution

tank with a weak alkaline solution.

2. Remove parts from the hot solution and wash

them with water until the hot solution is re-

moved.

Wet Disc Brake and Axle Assembly

NOTE: Before the assembly is cleaned, close or put

a cover over all openings. Breathers or vents in the

axle assembly are some examples of openings.

1. Use steam to clean the outside of the wet disc

brake and axle assembly.

INSPECT

NOTE: Inspect all the parts before assembling the

wetdiscbrake. Checkallpartsforwearandre-

place the damaged parts. Replacing worn or dam-

aged parts prevents the failure of the assembly later.

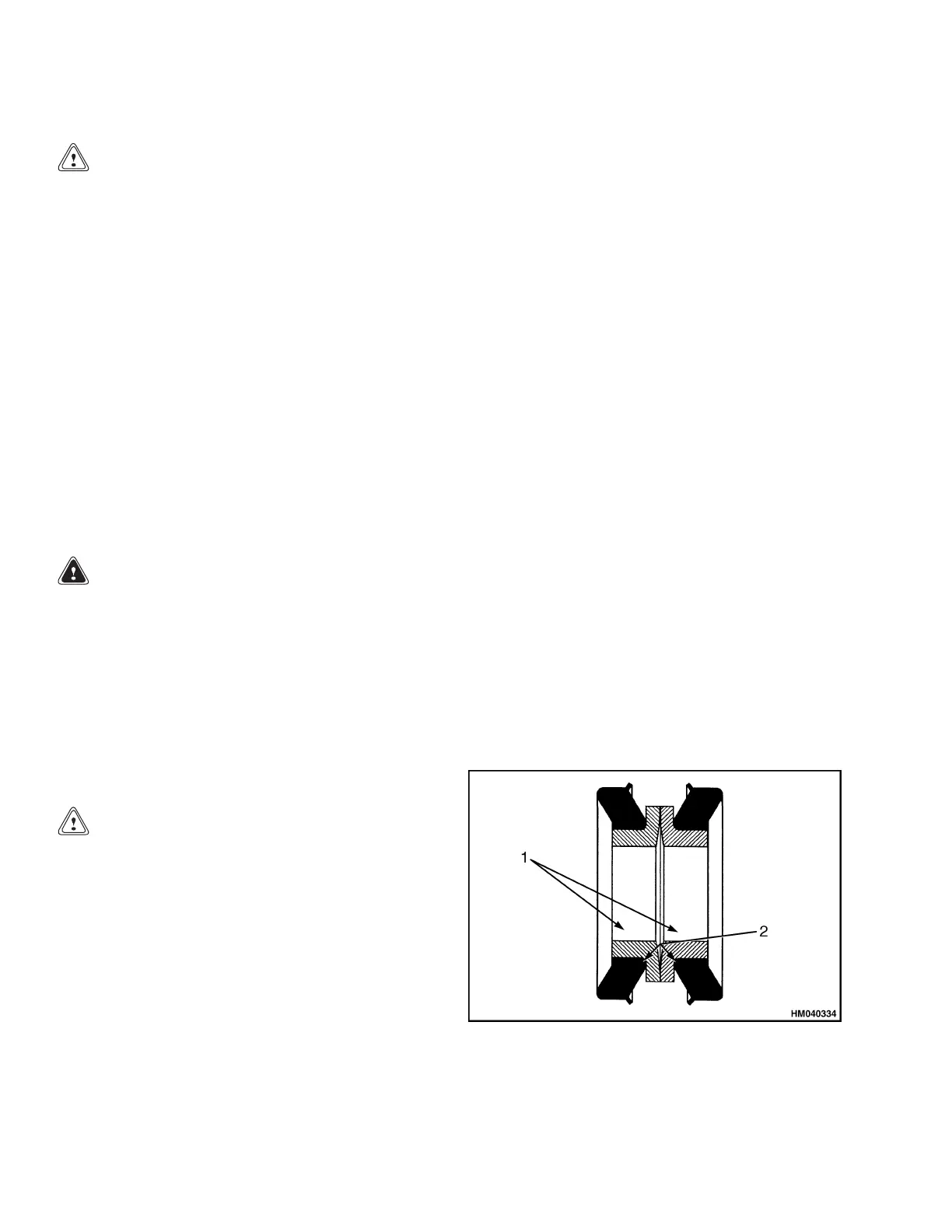

Face Seals

Inspect the rubber elements and metal rings for

wear, damage, or distortion. If there is a problem

with either ring, always replace both rings with a

matchedpairofrings. Amatchedpairistwonew

rings or two used rings that have been run together.

Do not use one new and one used ring or two used

rings that were not run together or leaks may occur.

SeeFigure19.

1. METAL SEALING RINGS

2. RUBBER ELEMENTS

Figure 19. Face Seal Assembly

8

Loading...

Loading...