Repair 1800 SRM 1038

2. Install the O-ring on the plug.

3. Put the spring guide inside the brake housing

below the plug hole. Verify the flat area of the

guide is against the housing.

4. Install the spring on top of the guide.

5. Put the plug and pin assembly in the hole in the

brake housing and through the return spring.

6. Apply and hold pressure on the plug while the

plug is installed into the housing. Verify that the

pin is correctly installed in the spring guide and

that the flat areas on the spring guide are against

the housing. See Figure 15.

7. When the threads fully engage the housing, re-

leasethepressureontheplug.SeeFigure17.

8. Tighten the plug to 60 to 75 N•m (44 to 55 lbf ft).

9. Put the brake housing on a bench. The cover side

of the housing must be toward you.

10. Install the disc spacer in the bottom of the brake

housing. See Figure 14.

NOTE: If a thick-splined stationary disc is used in-

steadofthespacerandstandardstationarydisc,it

must be installed against the housing. Next, install

a friction disc followed by a standard stationary disc

and continue to complete the stack. Brake housings

aredesignedtouseonlyonetypeofdiscconfigura-

tion. Do not interchange parts.

11. Install the disc pack.

a. Apply the same fluid used in the brake cool-

ing system to the disc surfaces as the discs

are installed.

b. Install a stationary disc in the housing. The

first stationary disc must be against the disc

spacer. Make sure the splines on the outer

diameter of the stationary disc engage the

splines in the brake housing. Verify the wide

spaces on the outer diameter of the disc are

over the return spring assemblies. See Fig-

ure 13.

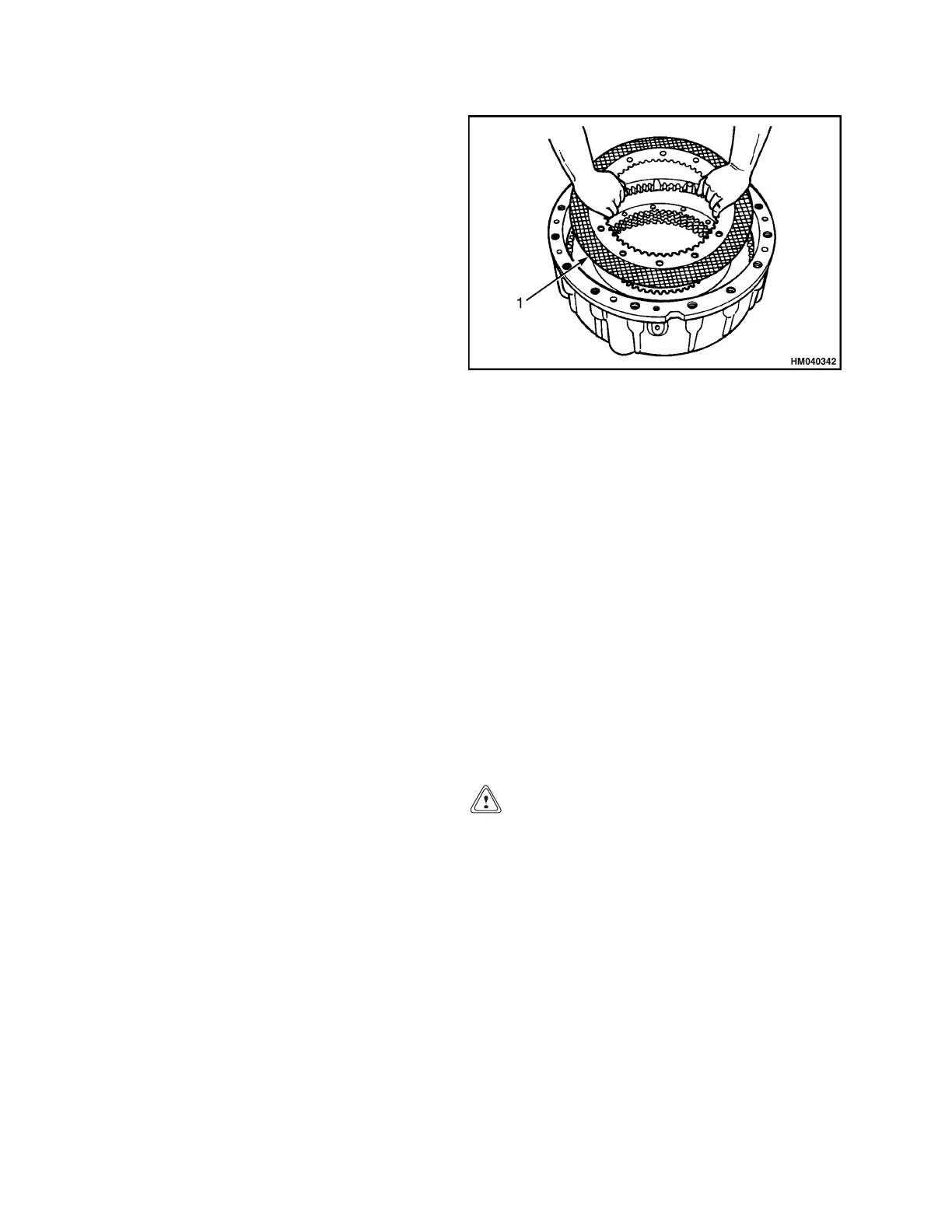

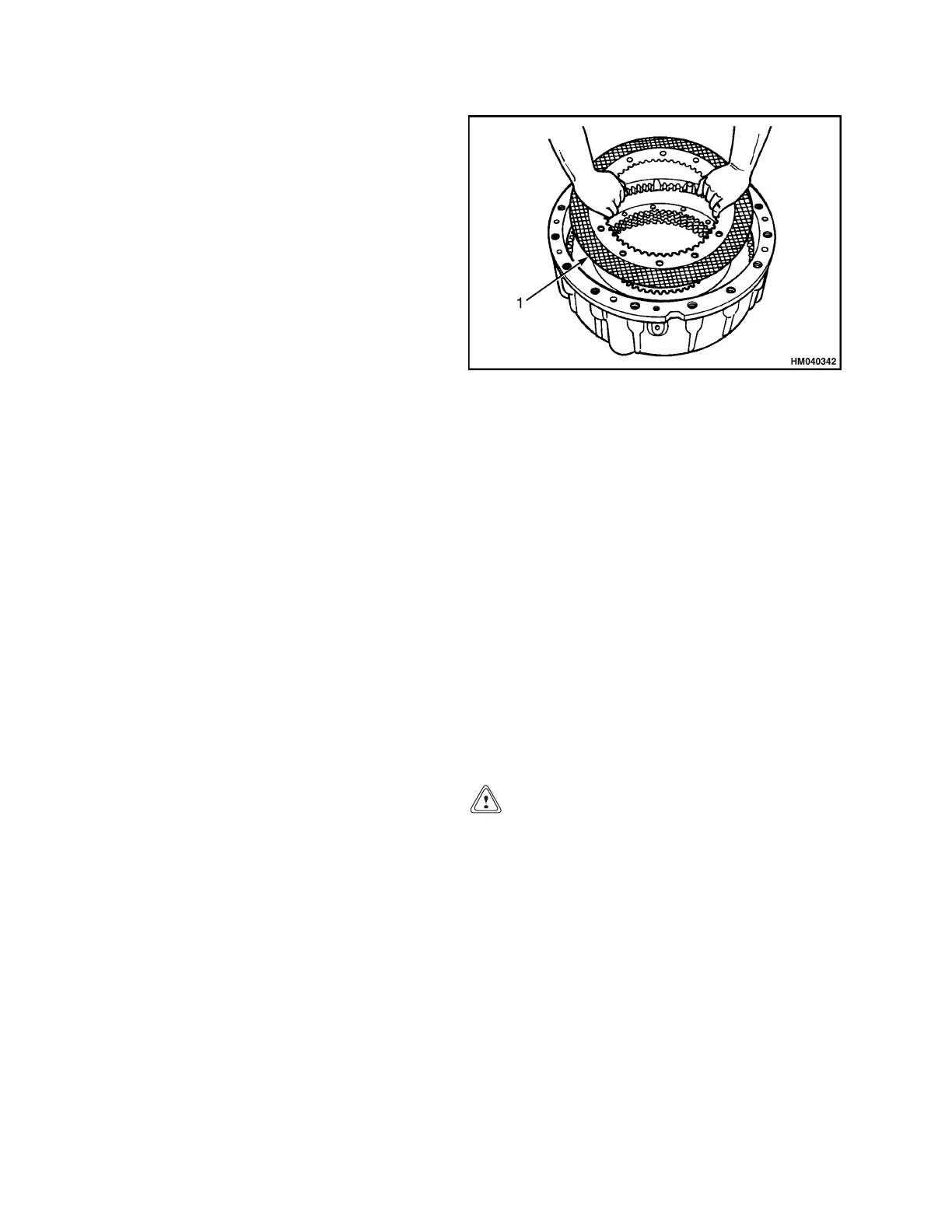

c. Install a friction disc in the housing. See

Figure 20.

1. FRICTION DISC

Figure 20. Friction Disc

d. Complete the installation of the disc pack.

Repeat steps Step b and Step c until the com-

plete disc pack is installed.

12. Align all of the teeth on the inner diameter of the

friction discs. When the discs are aligned, the

wheel hub can be installed without damaging the

discs.

13. Lubricate the outside diameter of the piston, the

housing bore, and the seals with the same fluid

used in the brake system.

14. Lower the piston into the housing until the piston

is installed on the guides of the return springs.

Verify the surfaces on the piston and the hous-

ing are not damaged when the piston is installed.

See Figure 21.

CAUTION

To prevent housing or piston damage, use fin-

gers or a non-metallic object to install the seals

and round spacer. Fluid can leak between the

housing and the piston if the surfaces are dam-

aged.

NOTE: The sealing arrangement between the piston

and the housing consists of one spacer and two piston

seals. See Figure 22.

15. Put the first seal in the space between the hous-

ing and the piston. The rubber part of the seal

must be toward you. Push on the seal until

the complete plastic bottom surface of the seal

touches the shoulder of the piston. See Fig-

ure 23.

10

Loading...

Loading...