4000 SRM 736 Description and Operation

General

This section contains the description, operation, and repair procedures for the masts. Information on sideshift

carriage is also included in the section.

Description and Operation

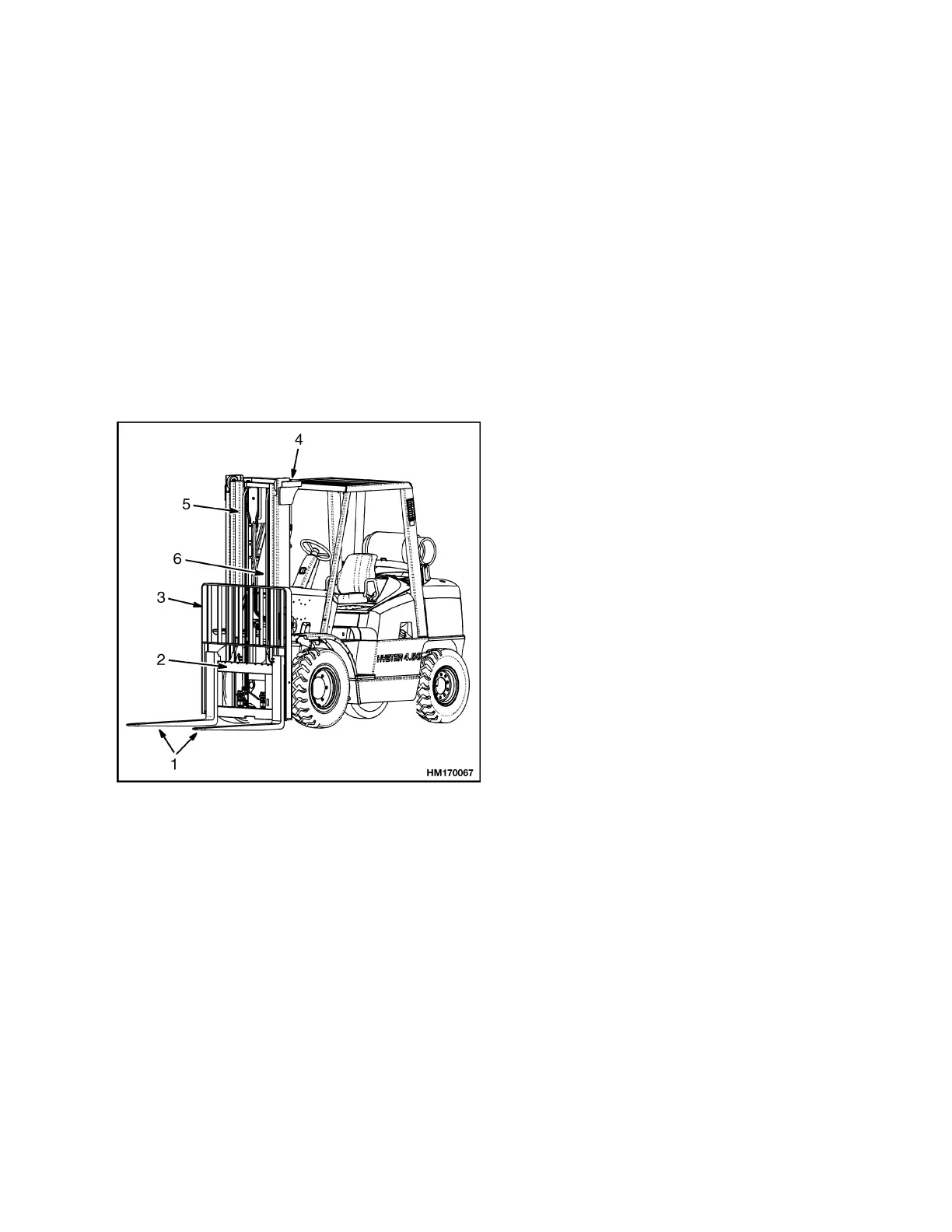

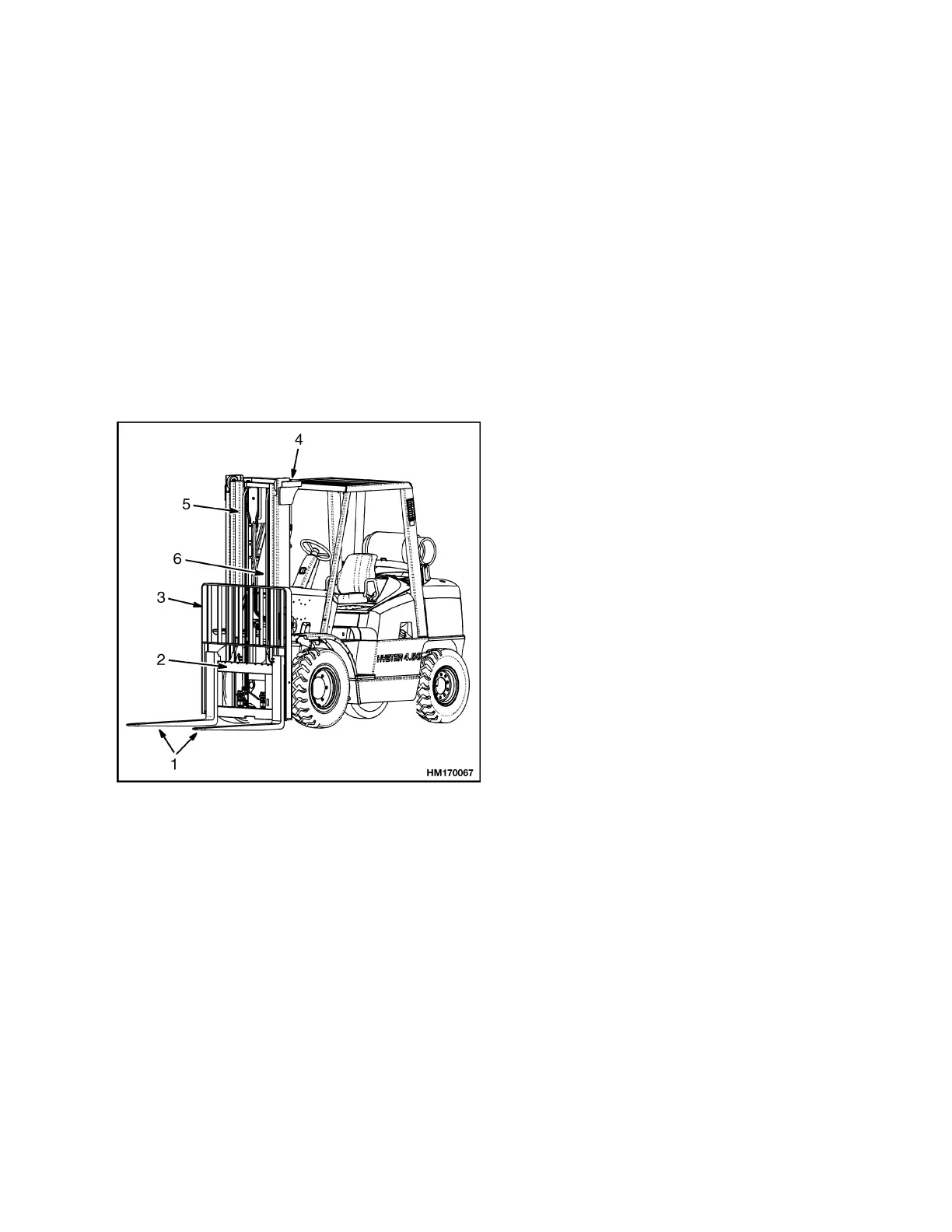

Vertical frames of a mast are called weldments. See

Figure 1. Channels, load rollers, and crossmembers

are parts of the weldments. Channels on each side

of the weldment are support members of the mast

and tracks for load rollers. While lifting and lowering

a load, large forces are put on the mast assembly.

Load rollers reduce the friction between the channels

when the weldments move vertically.

1. FORKS

2. CARRIAGE

3. LOAD BACKREST

EXTENSION

4. OUTER

WELDMENT

5. INNER WELDMENT

6. LIFT CYLINDER

Figure 1. Mast Components

The mast can tilt forward and backward. Tilt cylin-

ders are installed between the frame of the lift truck

and outer weldment of the mast. For H3.50-5.50XM

(H70-120XM) lift trucks, the pivot mounts at the bot-

tom of the outer weldment connect the mast to the

lift truck. During tilt operation, the mast rotates on

pivot pins in the frame.

For S3.50-5.50XM and E3.50-5.50XL

3

(E70-120XL

3

)

model lift trucks, mast mounting hangers are at-

tached to the drive axle and connect the mast to the

lift truck. During tilt operation, the mast rotates on

the drive axle.

CARRIAGES

The carriage is a separate section that moves on load

rollers within vertical channels of the inner weld-

ment. Forks or other types of load handling equip-

ment are attached to the carriage. A load backrest

extension is installed on the carriage.

A sideshift carriage permits the operator to hydrauli-

cally change the lateral position of the load handling

device on the carriage.

TWO-STAGE MAST WITH LIMITED

FREE-LIFT

The two-stage mast with limited free-lift (LFL) has

two weldments, an outer weldment and an inner

weldment. See Figure 2. Outer weldment is con-

nected to the lift truck by pivot mounts and tilt

cylinders. The top of the outer weldment and the

base of the inner weldment have one load roller on

each side. These load rollers travel along channels

of the weldments. The angle of the load rollers per-

mits them to control the forces from the front, back,

and sides of the mast. Shims on the load rollers

control lateral clearance between weldments and

load rollers. Strip bearings are installed at the top of

each side of the outer weldment. Strip bearings keep

correct clearance (forward and backward) between

outer weldment and inner weldments.

1

Loading...

Loading...