Description and Operation 4000 SRM 736

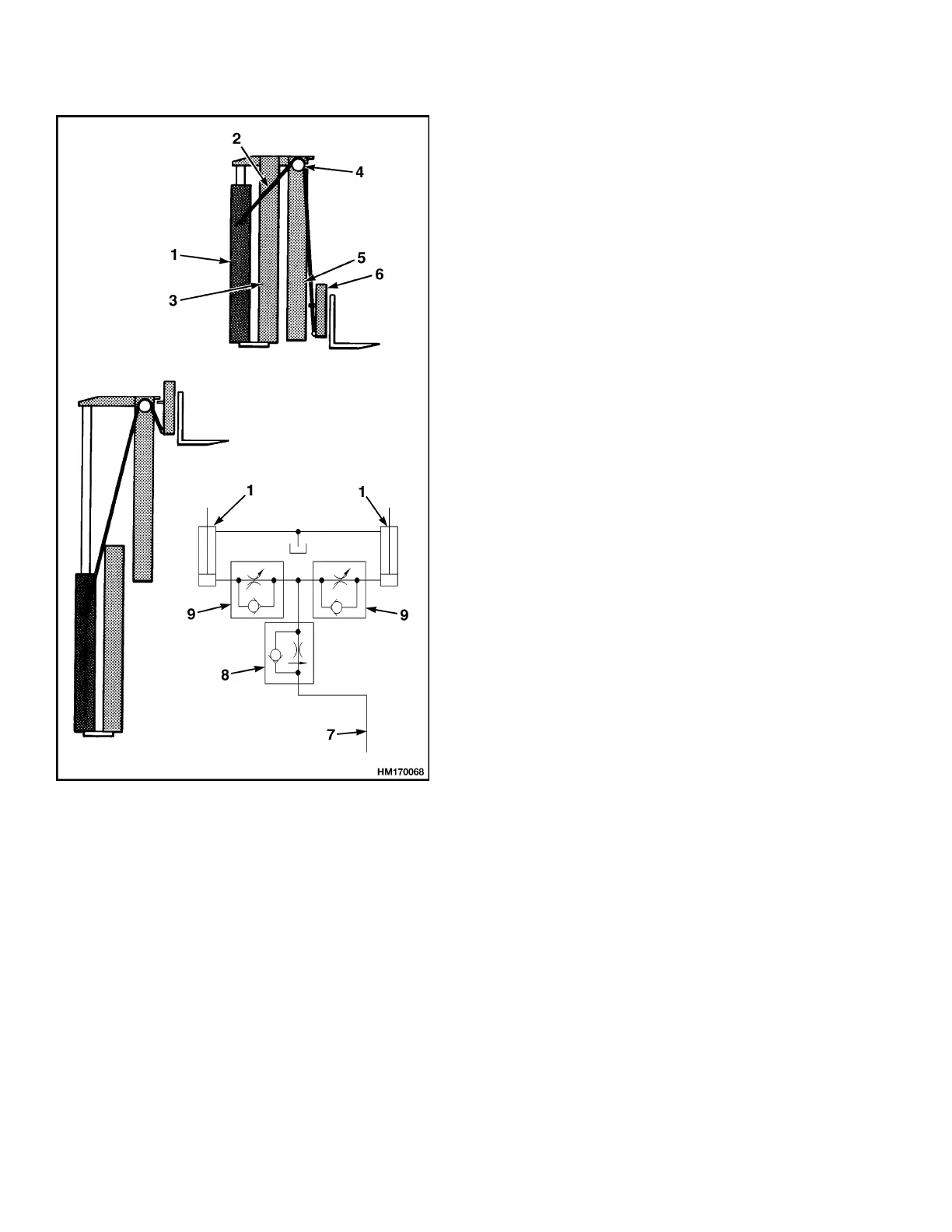

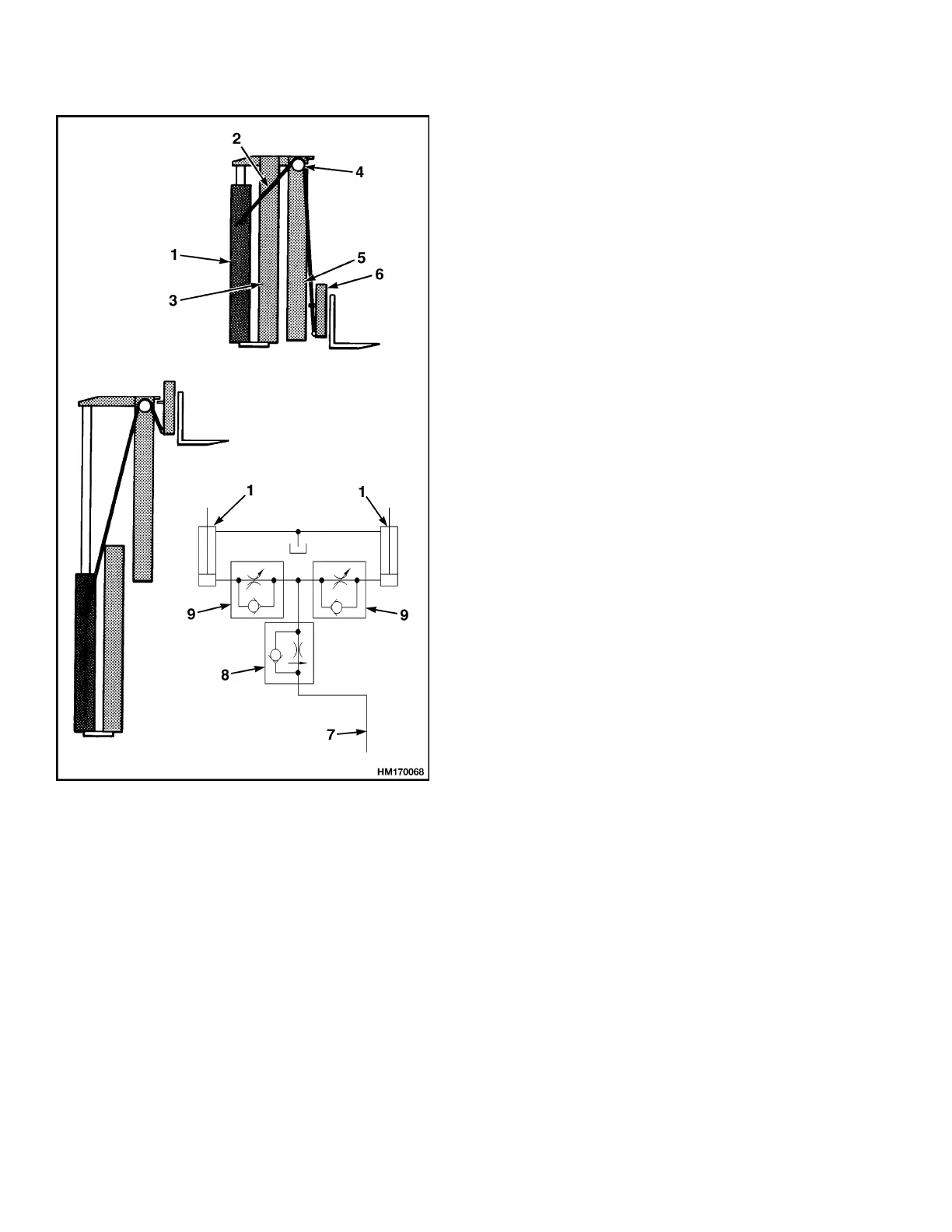

1. LIFT C

YLINDER (2)

2. LIFT CHAIN

3. OUTER

WELDM

ENT

4. CHAIN SHEAVE

5. INNER WELDMENT

6. CARRIA

GE

7. FROM M

AIN

CONTROL VALVE

8. EXTERNAL

LOWER

ING

CONTROL VALVE

9. INTERNAL

LOWER

ING

CONTROL VALVE

Figure 2. Two-Stage Mast With Limited

Free-Lift

The two-stage mast with limited free-lift has two sin-

gle-stage lift cylinders. Lift cylinders are installed at

the back of the outer weldment. The base of each lift

cylinder is held on a mount at the bottom of the outer

weldment by brackets. The top of each lift cylinder

(cylinder rod) fits into a guide at the top of the inner

weldment. A clamp holds the top of the lift cylinder

in position on the outer weldment. Operation of lift

cylinders extends and retracts the inner weldment.

Two lift chains control the movement of the carriage.

Chains are fastened to mounts near the top of the

outer weldment. The chains go up and over chain

sheaves on inner weldment and then connect to

the carriage. When lift cylinders extend, lift chains

transfer the force from lift cylinders to the carriage.

When lift cylinders retract, weight of the load, car-

riage, and inner weldment push oil from the lift cylin-

ders. Oil flows from lift cylinders, through lowering

control valves, main control valve, and then to the

hydraulic tank.

TWO-STAGE MAST WITH FULL FREE-LIFT

The two-stage mast with full free-lift (FFL) has an

inner weldment, an outer weldment, and three sin-

gle-stage lift cylinders. See Figure 3. It is called a

free-lift mast because the carriage can travel to the

top of the inner weldment without increasing mast

height. The free-lift mast has load roller and strip

bearing arrangements similar to the two-stage mast

with limited free-lift.

Two main lift cylinders are installed at the back of

the outer weldment. The base of each lift cylinder

sits in a mount at the bottom of the outer weldment.

The hydraulic fitting for each lift cylinder goes

through a hole in the mount. The top of each lift

cylinder (cylinder rod) fits into guides at the top of

the inner weldment.

Free-lift cylinder is installed in the inner weldment.

Main lift cylinder on the right side of the mast and

the free-lift cylinder each have an internal lower-

ing control valve. A single external lowering con-

trol valve is connected by tubing to all lift cylinders.

Two chain sheaves are installed on the cylinder rod

of the free-lift cylinder. Lift chains are connected to a

mount behind the free-lift cylinder. The chains then

go over the sheaves and are connected to the carriage.

Three lift cylinders are connected by hoses and tub-

ing. To extend the mast, oil from main control valve

flows to all lift cylinders at the same time. Free-lift

cylinder raises first because it lifts the least amount

of weight. Free-lift cylinder raises the carriage to the

top of the inner weldment. After the free-lift cylinder

reaches the end of its stroke, main lift cylinders be-

gin to extend and raise the inner weldment.

2

Loading...

Loading...