Secure joints using appropriate solvent cement to bond the respective pipe material

(Canada: CPVC cement approved under ULC-S636, in accordance with its

manufacturer instructions; USA: PVC (ASTM D2564), or PVC/ABS (D2235) - Use

transition glue anywhere that PVC and CPVC are joined. Follow the cement

manufacturer’s instructions closely when joining various components. For PP,

connections shall be secured using approved retainer clips supplied by the respective

PP manufacturer.

Check that vent connections are liquid and pressure tight. Prior to firing the boiler, and

before any of the venting run is concealed by the building construction, test the exhaust

joints under fan pressure with the vent blocked, using a soap and water solution. The

installer must fill the condensate trap prior to testing.

Coat all joints with an approved leak test solution just as you would joints in a gas line,

and make sure there are no leaks. We suggest attaching a tag on the vent line near the

condensate drain tee with the type of test, the date and the installer’s name.

Re: venting passage through ceiling and floor:

Confirm material meets local codes including fire stopping requirements.

Check the local jurisdiction on the minimum initial length of pipe that should be

exposed or accessible for inspection.

Follow the local codes for pipe clearances - no IBC requirements.

Ensure that piping is liquid and pressure tight.

3.7.4.1 Air intake and exhaust vent length allowance

Warning

Follow all installation instructions supplied by the piping and fitting manufacturer.

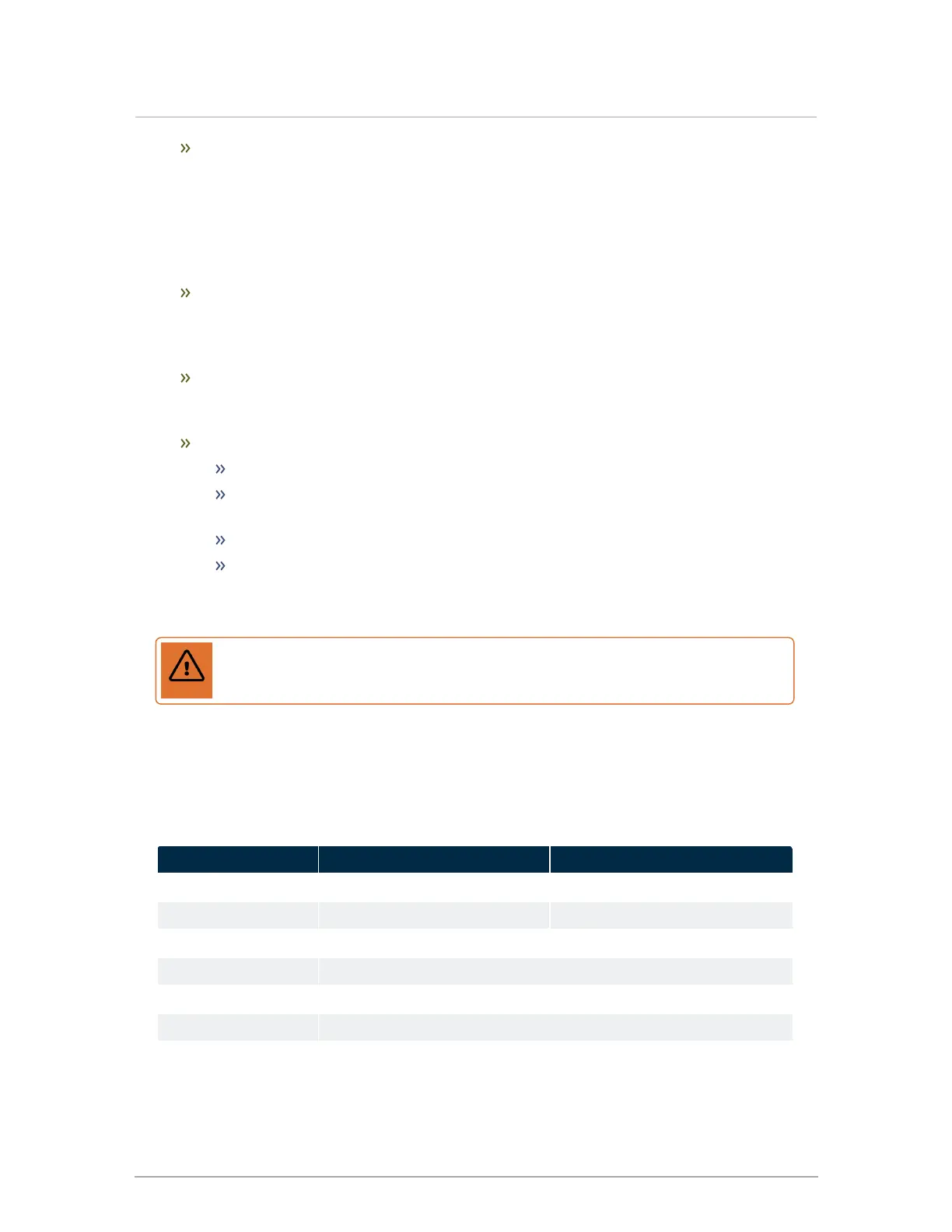

The maximum vent lengths shown are separate for the intake and exhaust. For example, for a

maximum vent length of 100 ft, the exhaust can travel a maximum of 100 equivalent ft and the

intake can travel a maximum of 100 equivalent ft. Any unused vent lengths used on one side

can not be added to the other. Equivalent feet of any elbows, termination kits, or flexible pipe

must be subtracted from the maximum length using the table below:

Intake/Exhaust CX150 CX199

2-inch rigid pipe 50 ft (max.) Not permitted

3-inch rigid pipe 170 ft (max.) 100 ft (max.)

90° elbow Allow 8 feet for each 90° elbow

90° long sweep elbow Allow 5 feet for each 90° elbow

45° elbow Allow 3 feet for each 45° elbow

PP 87-90° elbow Allow 8 feet for each 87-90° elbow

2-inch Stainless

Sidewall Terminal (P-

Not permitted Not permitted

Loading...

Loading...