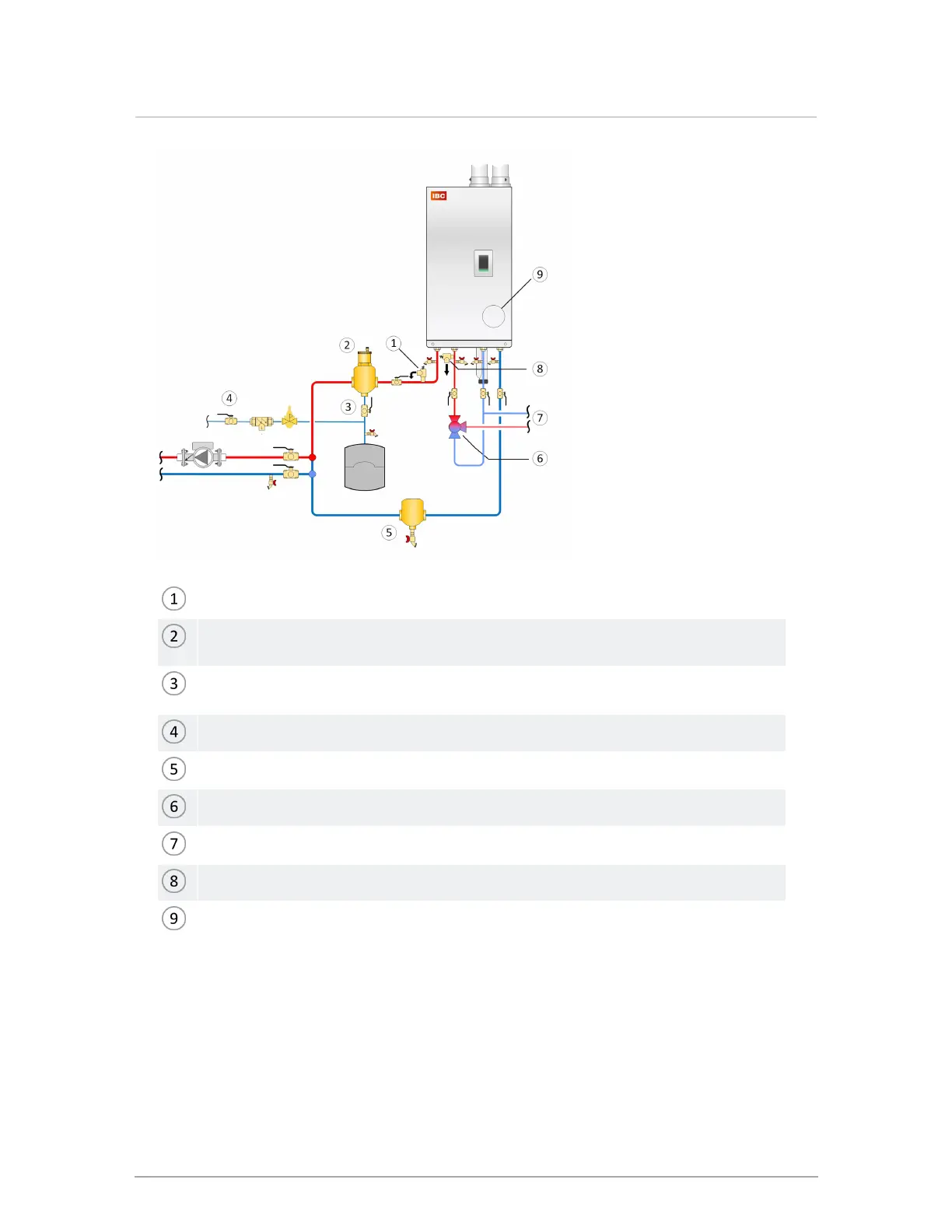

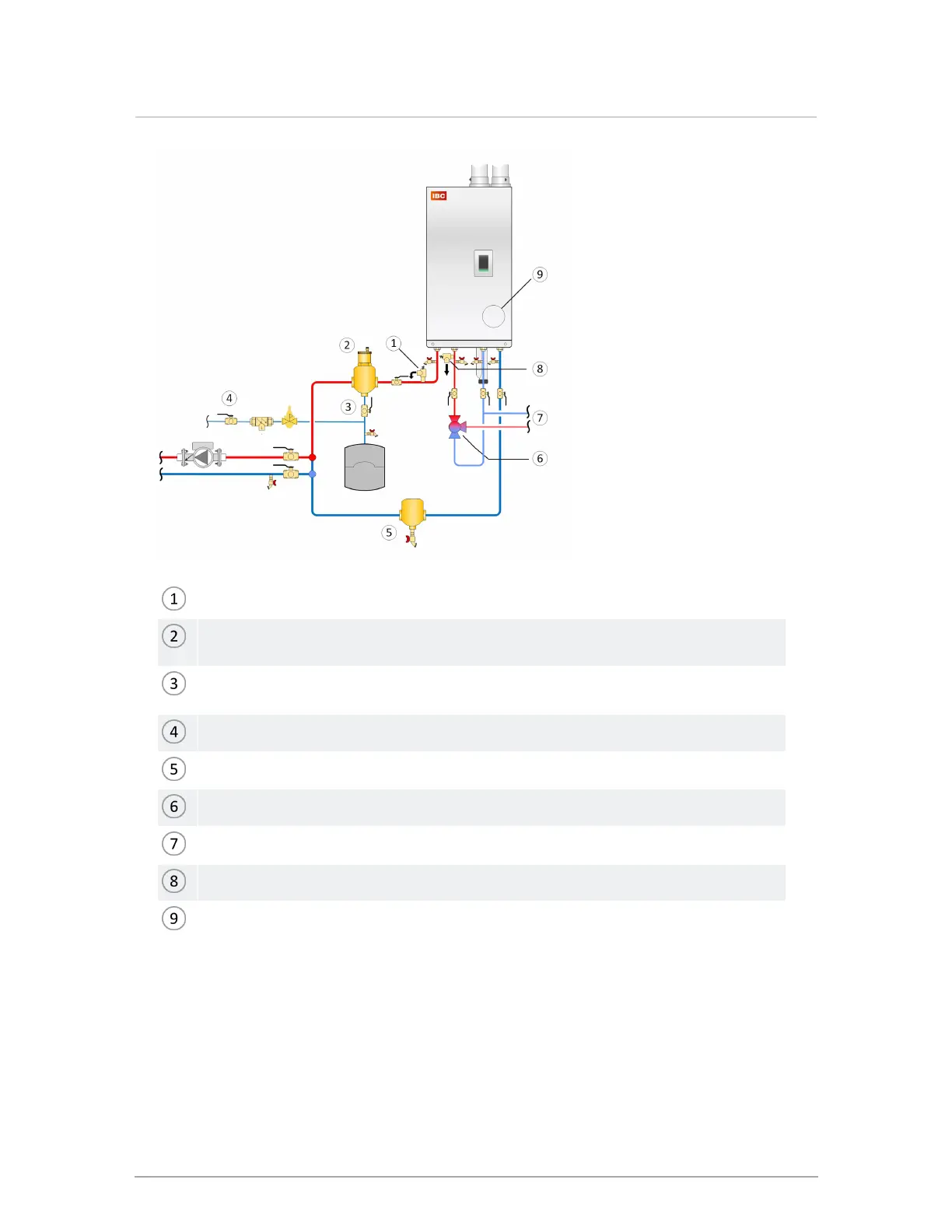

Isolation valve between boiler and relief valve not permitted

Microbubble air eliminators are best installed where the fluid is at the highest

temperature and lowest pressure

Expansion tank connection (point of no pressure change) should be on the suction

side of the circulator, with minimal pressure drop between.

Fill station with isolation valve closed, or fill tank.

Dirt separator recommended

Thermostatic tempering valve (if required by local code)

Domestic water

DHWrelief valve

Primary loop circulator built into return side of boiler

Figure 30 Boiler trim options - single boiler

Fluid fill is most often accomplished by using a boiler regulator and fill valve set at 12 psig or

more, with the appropriate backflow prevention device as required by local code. This is

acceptable in areas where municipal water or well water has been treated and filtered to

remove excessive minerals and sediment, and water chemistry is known to be suitable for

Loading...

Loading...