INSTALLATION AND OPERATION INSTRUCTIONS

1-16

SL 10-85 G3, SL 14-115 G3, SL 20-160 G3, SL 30-199 G3 MODULATING GAS BOILERSSL 10-85 G3, SL 14-115 G3, SL 20-160 G3, SL 30-199 G3 MODULATING GAS BOILERS

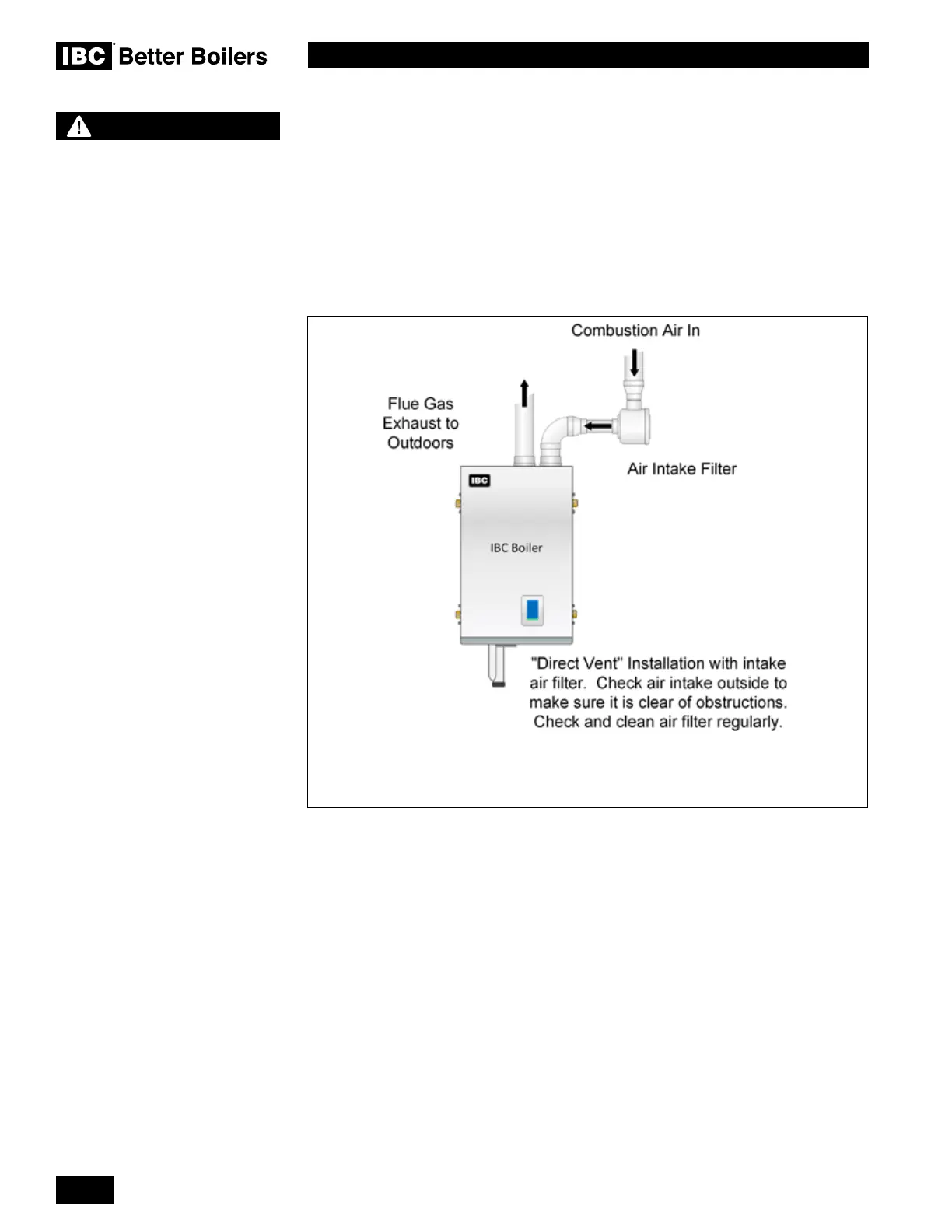

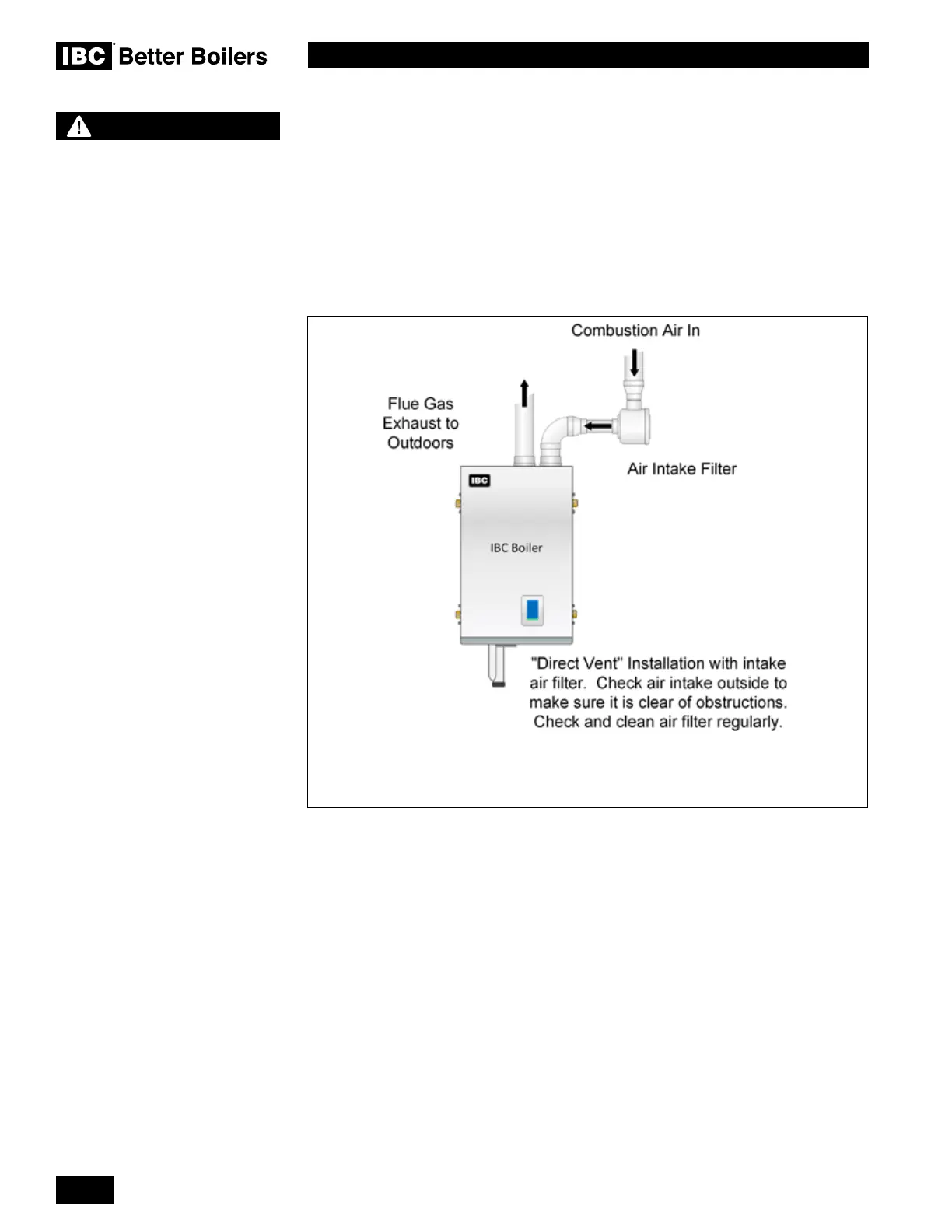

1.4.9 Combustion Air Filtration

If combustion air contamination from ingested particulate matter is a concern in any

installation, an optional air intake lter may be installed. IBC supplied air intake lters

have a known pressure drop and fouling factor and should be used as a component of the

combustion air system according to the allowable intake length in Table 4.

IMPORTANT: Under no circumstances should a third-party air lter be installed on

an IBC boiler without proper evaluation and written approval of the IBC Engineering

Department.

1.4.10 Closet Installations

For installations in a conned space (such as a closet), ventilation openings may be

needed through a door or wall to prevent excessive heat from building up inside the

space.

The boiler shall not be exposed to ambient conditions above 122°F (50°C) or below 32°F

(0°C).

NOTE

Combustion fan blockages

can occur when environmental

particulate and foreign matter

contaminants (leaves, dust,

dandelion & cottonwood uff,

etc) are drawn into the air intake.

In areas where this problem is

suspected to be an issue, our

optional air intake lter should be

installed.

Filters should be checked and

cleaned or replaced on a regular

schedule based on the severity

of the problem.

Figure 21: Direct vent - intake, exhaust system with optional air intake lter (ltration may

also be used on indoor air applications as required)

Loading...

Loading...