3-3

STARTUP AND COMMISSIONING

SL 10-85 G3, SL 14-115 G3, SL 20-160 G3, SL 30-199 G3 MODULATING GAS BOILERS

To verify the proper operation of the gas valve in the eld, the following procedure must

be carried out by a qualied technician (see Figure 44 for details of the gas valve and

pressure system ).

1. With a small (1/8” or 3 mm) at screwdriver, open the inlet gas supply pressure test

port by turning its center-screw one full turn counterclockwise. Attach a manometer

to the pressure test port and turn on the gas to the appliance. The static manometer

reading should be ideally 7” w.c. for Natural Gas and 11” w.c. for Propane. Minimum

and maximum static pressure should be between 5” and 14” w.c. Monitor pressure

throughout the commissioning procedure. Pressure may droop up to 1” to 2” w.c. at

high re but under no circumstances should it drop below 4” w.c. at the gas valve

inlet test port.

2. Allow the boiler to ignite / run against a large load to maintain high re.

You can temporarily dene a load as Manual for direct control of the boiler ring rate

as long as the load number is associated with a pump that can remove the heat.

Closing the corresponding Therm connection initiates manual ring.

3. With a combustion analyzer probe in the ue gas test port, turn the Gas:Air Ratio

Adjustment screw (see Figure 44) to achieve results (see Table 7 below for the

corresponding CO

2

values - set the CO

2

target at high re). This screw offers very ne

adjustment, and may require several turns.

Note: This screw has signicant backlash. When changing direction of turn, it may

take up to a full turn before any change is indicated on the analyzer reading. Clock

the gas meter to conrm full maximum rating plate input.

4. Conrm the minimum re level settings. Re-dene the load as “Manual Control”.

Use Heat Output in “Congure Load x” to control the output as needed. The reading

should be within the Low re range. Re-test at high re.

5. Turn boiler off by removing the call for heat (use the Heat Load Conguration screen

to turn load to off if no other ready means available), then remove the manometer

connections, and turn the centre-screw in the manifold pressure test port 1 full turn

clockwise. Ensure fully closed, but not over-tightened. Restore gas and soap test for

leaks.

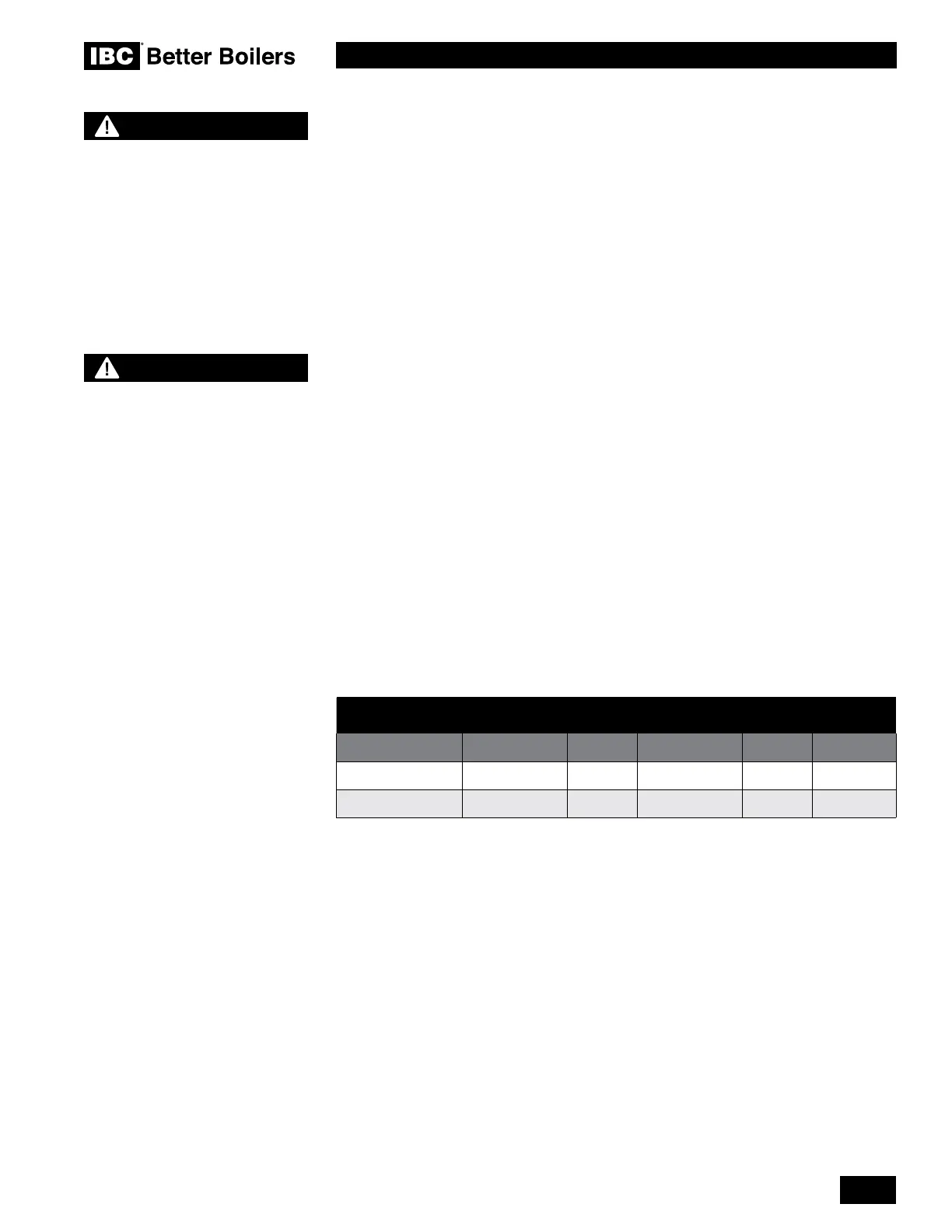

FUEL HIGH FIRE LOW FIRE

CO MAX

PPM

RANGE TARGET RANGE TARGET

Natural Gas 9.0 – 10.0 9.5 8.2 – 9.2 8.7 < 150

Propane 10.3 – 11.3 10.8 9.3 – 10.3 9.8 < 250

Note: Low Fire CO

2

should be at least 0.5% lower than High Fire CO

2

Table 7: Combustion test target ranges - CO

2

/ Maximum CO

DANGER

Making adjustments to the IBC gas

valve without a properly calibrated

gas combustion analyzer and by

persons who are not trained and

experienced in its use is forbidden.

Failure to use an analyzer can

result in an immediate hazard.

WARNING

Check the rating plate of the

boiler to ensure it is congured

for the fuel you are using. If the

fuel is incorrect for the appliance,

a conversion kit must be ordered

from IBC and the gas valve

adjusted accordingly.

Failure to perform the required

fuel conversion can result in an

immediate hazard.

Loading...

Loading...