If using Setup, load priority is simplified with options "very low",

"low", "high" or "very high". There's more precision in Advanced

Setup, where you can enter numeric values between 20 and 90 for

a priority load. Note: The priority value has to be different for each

load, but the priority scale values do not need to add up to 100 –

they are relative only to each other. A higher numerical value

means a higher priority.

Consider priority values as minutes. The difference between two

load priority values is the number of minutes the higher priority

load will operate before switching back to the lower priority load.

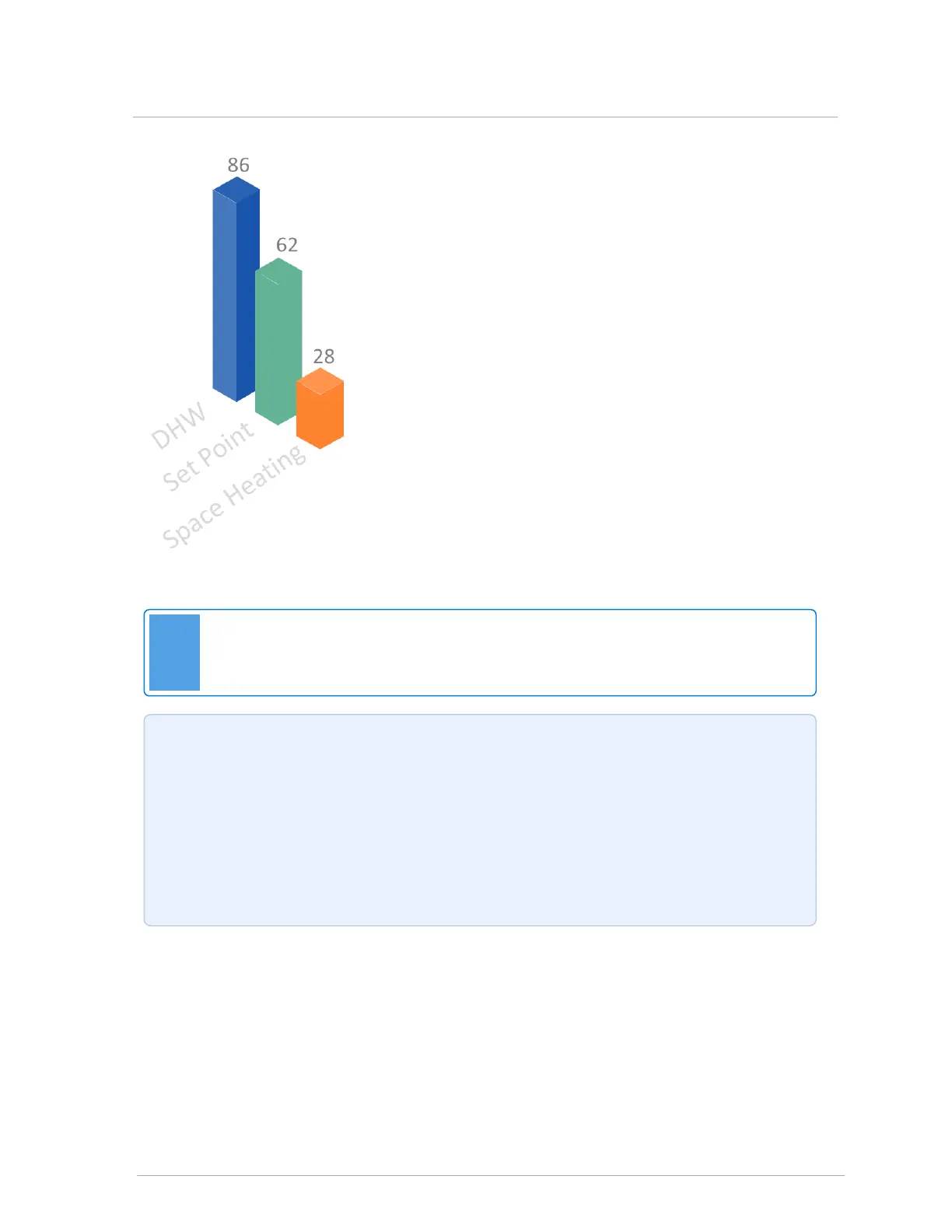

For example, if DHW has a priority of 86 and the Set Point load

has a priority of 62, the DHW load will run for (86-62) 24 minutes

before switching to the simultaneously calling Set Point load.

Following the initial cycle, the competing loads will switch back

and forth after a further 10-minute interval pending satisfaction of

one or both loads.

Figure 10 Default priority values by load type in Installer Settings

Note

Ensure that loads are set with a minimum of 15-minute differential between competing

loads.

Example: If baseboards (set up with Reset Heating as Load 3) are not providing the desired

heat, you can bring on baseboard run time sooner by increasing the priority value relative to the

other declared loads (e.g., changing the Load 3 preset value from 43 to 50 or reducing another

load’s value). Temperature targets for the under-served load can also be raised, in this

example.

To cause repeated unequal run times; for example, constant 35 vs 5-minute runs, you need to

integrate an external load removing relay or timer on one of the heat calls. Do not set each load

to the top value, and avoid equal ratings.

2.6 Setting load priority

Loading...

Loading...