23

Instruction Manual C100-AE

Restrictor adjustment with 2 masters

To get by relative small or big jet diameters good measuring results a restrictor adjustment is

recommended. For the adjustment close the restrictor completely ( turn right ) then open ( turn left ) it

according to the table.

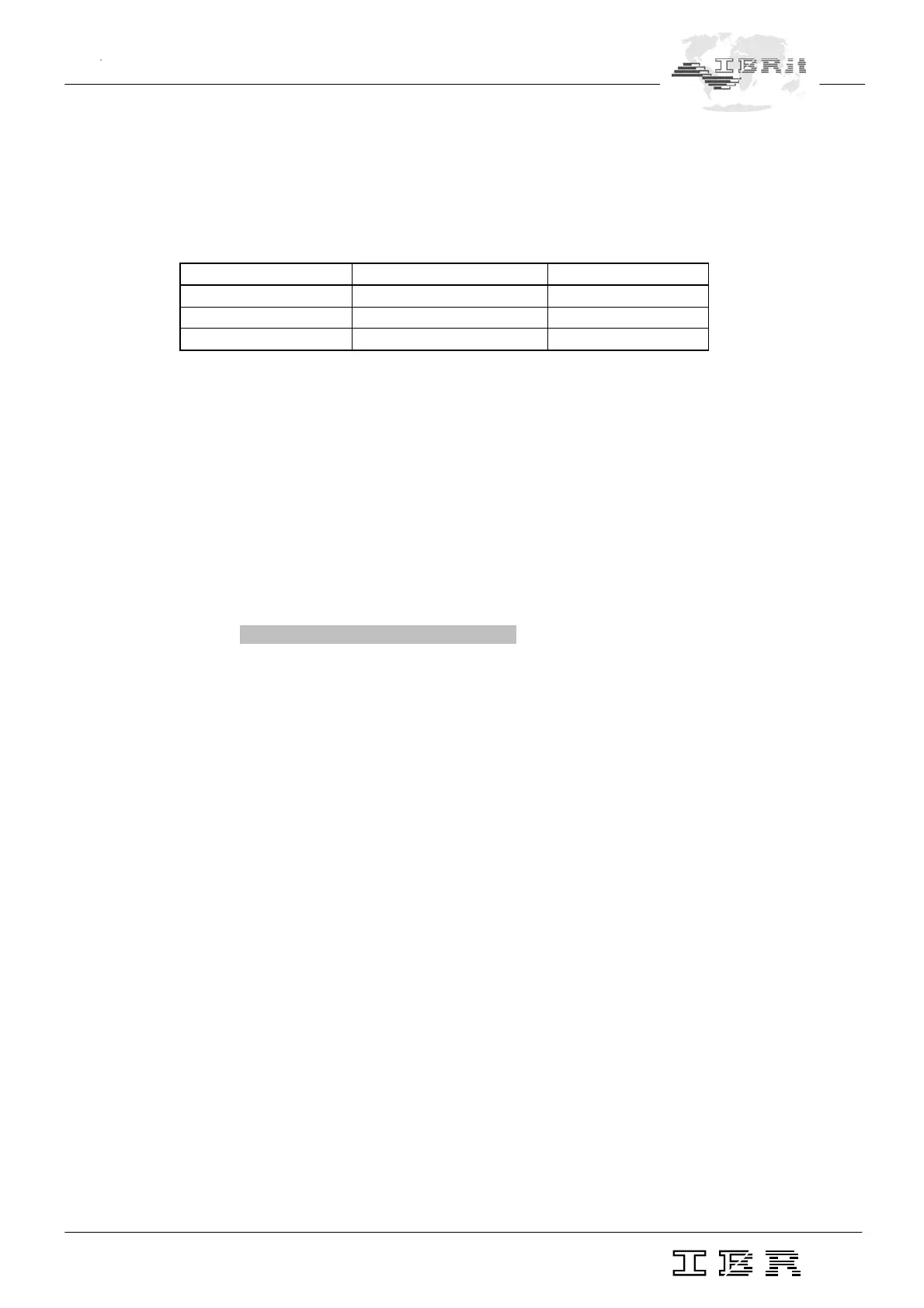

Jet size Measuring range Restrictor opening

< 1,0 mm < 50 µm 1 turn left

> 1,0 mm < 25 µm 2 turns left

> 1,0 mm > 25 µm 3 turns left

Note : The restrictor adjustments mentioned in the table are rough guiding values for

standard measuring heads and guaranties no optimal adjustment.

Improved restrictor adjustment on C100-AE - Gauges

1. The C100-AE gauge must be set into Measuring mode. If it is not set to Measuring mode, please

press the PRG/CAL key to leave the Programming mode.

2. Press the Ï and Ð keys for more than 3 seconds until the luminous displays MIN, MAX, TIR and

MEAN or Gauge 1…4 start flashing and confirm the Adjustment mode. When this mode is active the

gauges switches all factors and offsets automatically off and displays the true measuring value of the

measuring converter.

If "SECUrE" appears in the numeric display the keypad is locked. Refer to Setup menu "Automatic

adjustment" ( "0-triG." → Adb. on/oFF set to "on" ).

3. Change the restrictor adjustment till the display values of the MIN and MAX Master are laying

symmetrically around 0. ( that means both have the same absolute value )

Example : Display on MAX Master = 0.4573

Display on MIN Master = - 0.4600

4. When the restrictor has been adjusted, press the ENTER key to exit the Adjustment mode. The

message Load appears in the numeric display and all coefficients of the inputs are loaded once again.

The offset values cannot be retrieved. It is therefore necessary to perform a Gauge calibration before

starting work.

Restrictor adjustment with 3 masters

1. Close the restrictor ( turn right ) and open it for 1 turn left.

2. Do an automatic gauge calibration. ( Please see chapter 3.3 of this manual )

3. Measure the middle master and compare the measuring value with the master size.

If the measuring value and master size are identical the restrictor is optimal adjusted.

If the measuring value is different to the master size the restrictor adjustment has to be

changed. For this leave the gauge head inside the master and change the restrictor adjustment till

the measuring value is equal to the master size.

4. After changing the adjustment of the restrictor repeat the points 2. and 3. until the difference

between measuring value and master size is nearly zero.

Loading...

Loading...