4

Flame not established

1. If the flame is not established or proven during the initial

will enter a retry mode. There will be four more successive

attempts allowed each having a 15 second inducer purge

between attempts.

is still not established and proven there will be a 1 hour lock

out before the system will reset automatically. To reset the

on the 24 VAC power to the board. If the problem is not a

false flame, the board can also be reset by cycling the heat

detected when the gas valve is de-energized and there is no

flame), cycling the heat call will not reset the board.

Flame out

1. Flame out is considered when flame is lost during heating.

2. When a W signal is present and flame is lost and no longer

sensed, the gas valves will disengage until the next trial

for ignition. The circulating blower and inducer will remain

running.

3. If all retry attempts fail and the flame is still not proven,

there will be a 1 hour lock out before the system resets

automatically.

False flame

1. Flame out of sequence represents a scenario when flame is

sensed while gas valve is de-energized.

2. Inducer and Blower motors will be engaged (if not already

running) and keep running for as long as the fault condition is

present.

FLAME SENSE TROUBLESHOOTING TIPS

LOCKOUT FEATURES

There is a 5 minute self healing recovery which occurs if the

pressure switch is stuck open. The inducer will run for 150

seconds then enter a 5 minute self healing recovery. This cycle

will repeat until the pressure switch closes.

There will be a 1 hour lock out if the flame is not established and

the control will reset automatically.

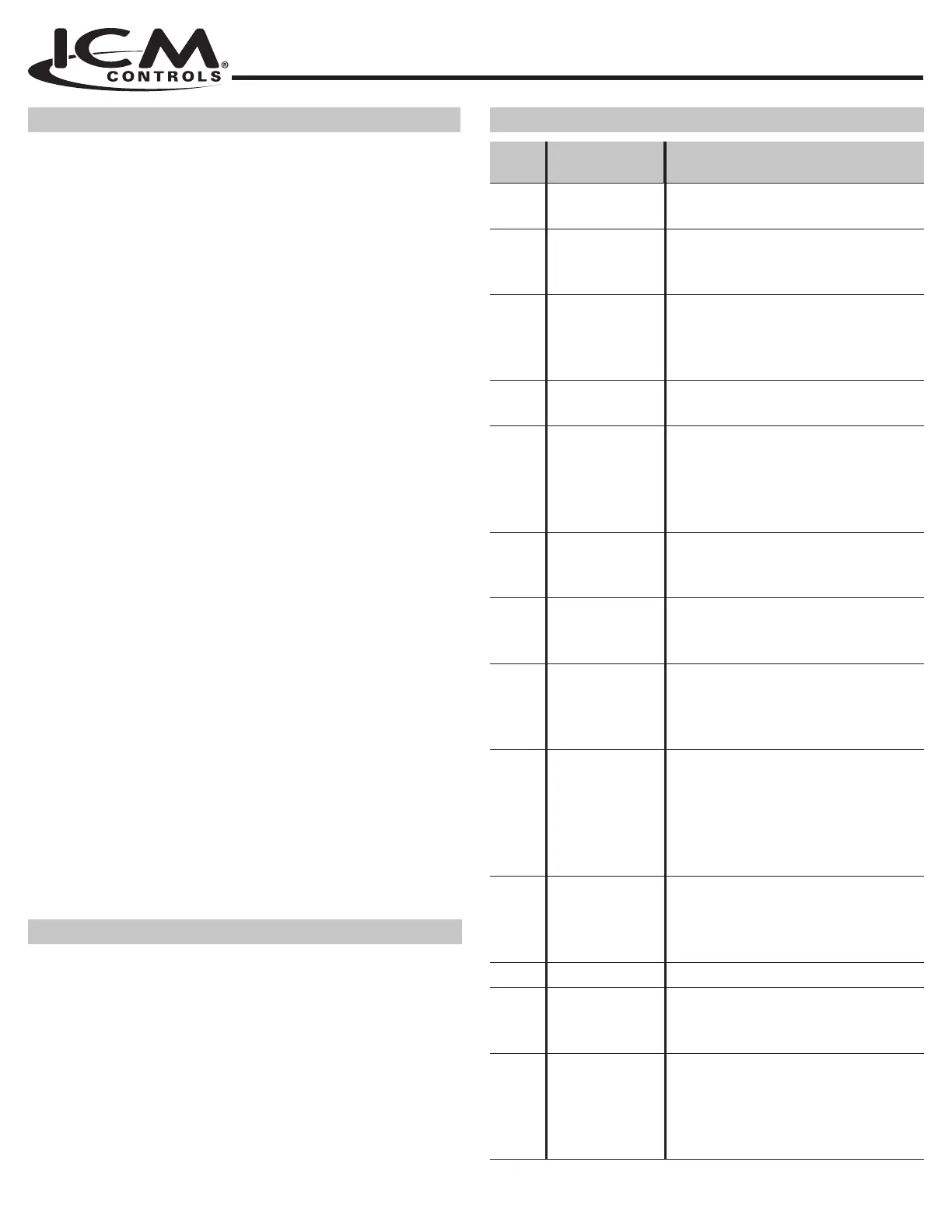

LED

Status Description Trouble Shooting Tips

ON

Normal

Operation

N/A

OFF

Control Board

Failure

Check for proper input voltage and

check the fuse; if not resolved replace

control.

1

Ignition Failure

Clean or replace the flame sensor,

check the igniter for proper operation &

input voltage, check the transformer’s

common is grounded to earth ground.

2

Pressure Switch

Stuck Closed

Check for contaminated or defective

pressure switch.

3

Pressure Switch

Stuck Open

Check for obstructed pressure switch

tubing or defective pressure switch.

Check for oxidation on terminals,

broken wires, or defective inducer

motor.

4

Limit Switch

Fault

Checked for blocked airflow, blocked

replace high limit switch if defective.

5

Flame Out of

Sequence

Check for intermittent or defective gas

valve and check for dirty or defective

flame sensor.

6

Roll Out Switch

Fault

Check for a cracked heat exchanger,

defective rollout switch, broken wires

on the roll out switch, or replace roll

out switch if required.

7 Weak Flame

Weak flame is caused by carbon build

up on the flame sensor, poor grounds,

or improper placement of flame

sensor . Clean or replace flame sensor,

reassure grounds, ensure flame sensor

is fully enveloped in the flame.

8

Miswired Gas

Valve

Check for shorted or miswired gas

valve, check harness wires for any

shorts or breaks, and check the

pressure switch for proper operation.

9 Unused N/A

10

Hot and Neutral

Reversed

Check for proper polarity of incoming

voltage on the primary and secondary

of the transformer.

11 Brownout

A brownout fault indicates a low

voltage condition. Check the voltage

on the primary and the secondary of

the transformer and ensure there is no

excessive load on the transformer.

LED FAULT CODES

Loading...

Loading...