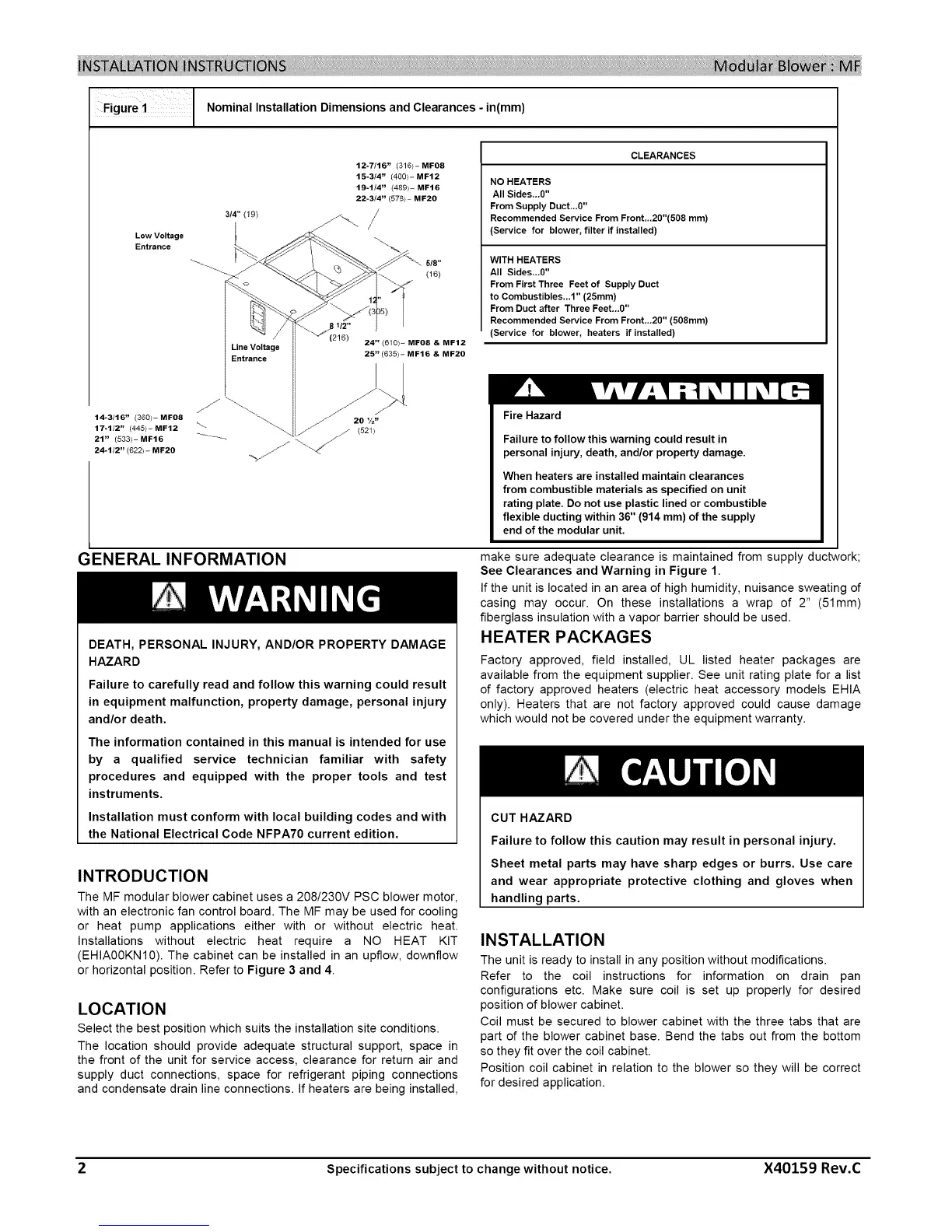

Figure i Nominal Installation Dimensions and Clearances-in(ram)

Low Voltage

Entrance

14-3/16" (360/- MFO8

17.112" (445/- MF12

21" (533/- MF16

24-1/2" (622/- MF20

314" (19)

12-7/16" (316/- MF08

15-3/4" (400)- MF12

19-1/4" (489)- MF16

22-3/4" (578)- MF20

Line Voltage | 24" (610)- MFO8 & MF12

Entrance l 25" (635)- MF16 & MF20

CLEARANCES

NO HEATERS

All Sides...0"

From Supply Duct_.0"

Recommended Service From Front_.20"(508 mm)

(Service for blower, filter if installed)

WITH HEATERS

All Sides...O"

From First Three Feet of Supply Duct

to Combustibles...1" (25ram)

From Duct after Three Feet...0"

Recommended Service From Front...20" (508mm)

(Service for blower, heaters if installed)

Fire Hazard

Failure to follow this warning could result in

personal injury, death, and/or property damage.

When heaters are installed maintain clearances

from combustible materials as specified on unit

rating plate. Do not use plastic lined or combustible

flexible ducting within 36" (914 mm) of the supply

end of the modular unit.

GENERAL INFORMATION

DEATH, PERSONAL INJURY, AND/OR PROPERTY DAMAGE

HAZARD

Failure to carefully read and follow this warning could result

in equipment malfunction, property damage, personal injury

and/or death.

The information contained in this manual is intended for use

by a qualified service technician familiar with safety

procedures and equipped with the proper tools and test

instruments.

Installation must conform with local building codes and with

the National Electrical Code NFPA70 current edition.

INTRODUCTION

The MF modular blower cabinet uses a 208/230V PSC blower motor,

with an electronic fan control board. The MF may be used for cooling

or heat pump applications either with or without electric heat.

Installations without electric heat require a NO HEAT KIT

(EHIA00KN10). The cabinet can be installed in an upflow, downflow

or horizontal position. Refer to Figure 3 and 4.

LOCATION

Select the best position which suits the installation site conditions.

The location should provide adequate structural support, space in

the front of the unit for service access, clearance for return air and

supply duct connections, space for refrigerant piping connections

and condensate drain line connections. If heaters are being installed,

make sure adequate clearance is maintained from supply ductwork;

See Clearances and Warning in Figure 1.

If the unit is located in an area of high humidity, nuisance sweating of

casing may occur. On these installations a wrap of 2" (51mm)

fiberglass insulation with a vapor barrier should be used.

HEATER PACKAGES

Factory approved, field installed, UL listed heater packages are

available from the equipment supplier. See unit rating plate for a list

of factory approved heaters (electric heat accessory models EHIA

only). Heaters that are not factory approved could cause damage

which would not be covered under the equipment warranty.

CUT HAZARD

Failure to follow this caution may result in personal injury.

Sheet metal parts may have sharp edges or burrs. Use care

and wear appropriate protective clothing and gloves when

handling parts.

INSTALLATION

The unit is ready to install in any position without modifications.

Refer to the coil instructions for information on drain pan

configurations etc. Make sure coil is set up properly for desired

position of blower cabinet.

Coil must be secured to blower cabinet with the three tabs that are

part of the blower cabinet base. Bend the tabs out from the bottom

so they fit over the coil cabinet.

Position coil cabinet in relation to the blower so they will be correct

for desired application.

2 Specifications subject to change without notice. X40159 Rev.C

Loading...

Loading...