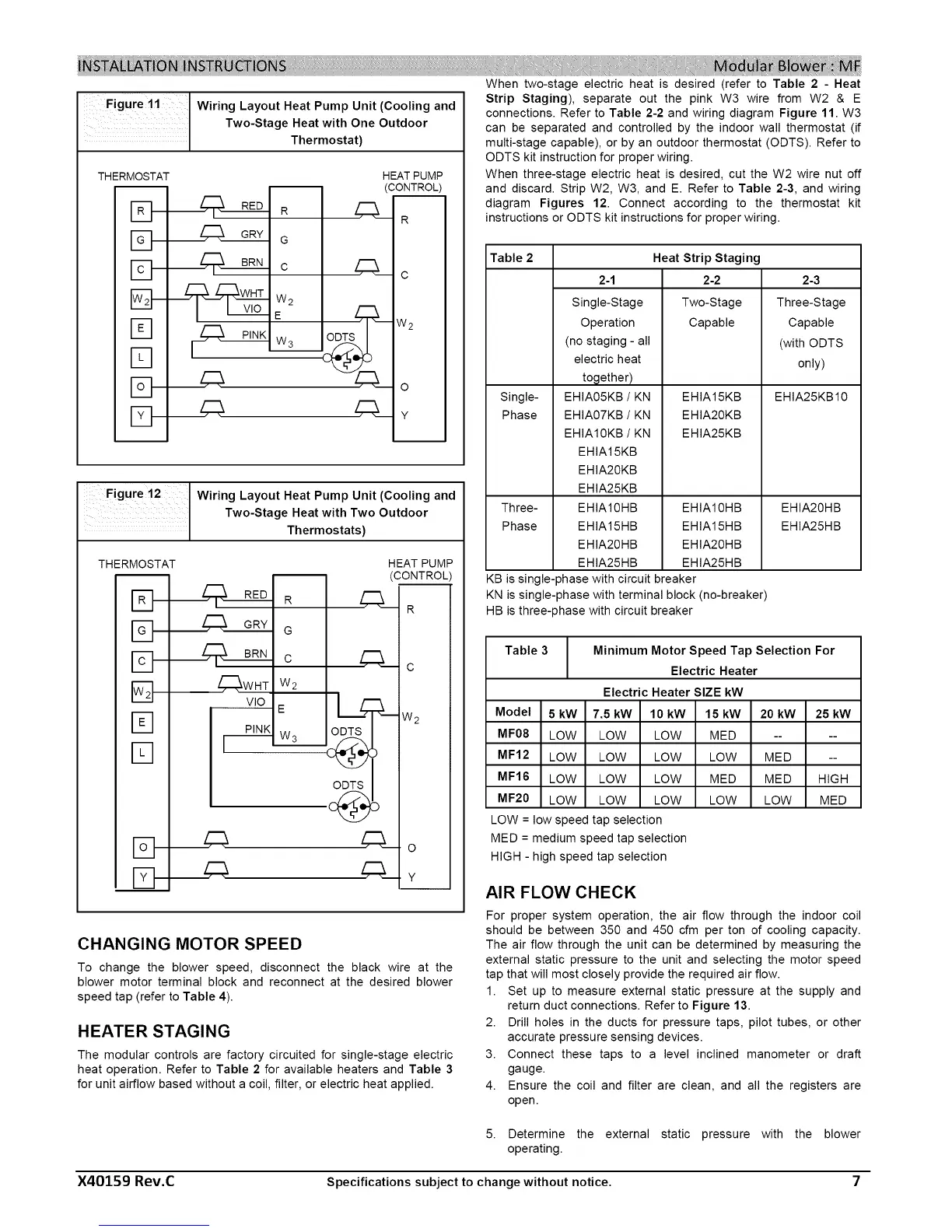

Wiring Layout Heat Pump Unit (Cooling and

Two-Stage Heat with One Outdoor

Thermostat)

THERMOSTAT

m

D-

J3-

D-

E3-

[-q

Fq

E]-

D-

m

R

G

c

W2

E

W3- ODTS

z;:5._

HEATPUMP

(CONTROL)

R

c

w2

o

Y

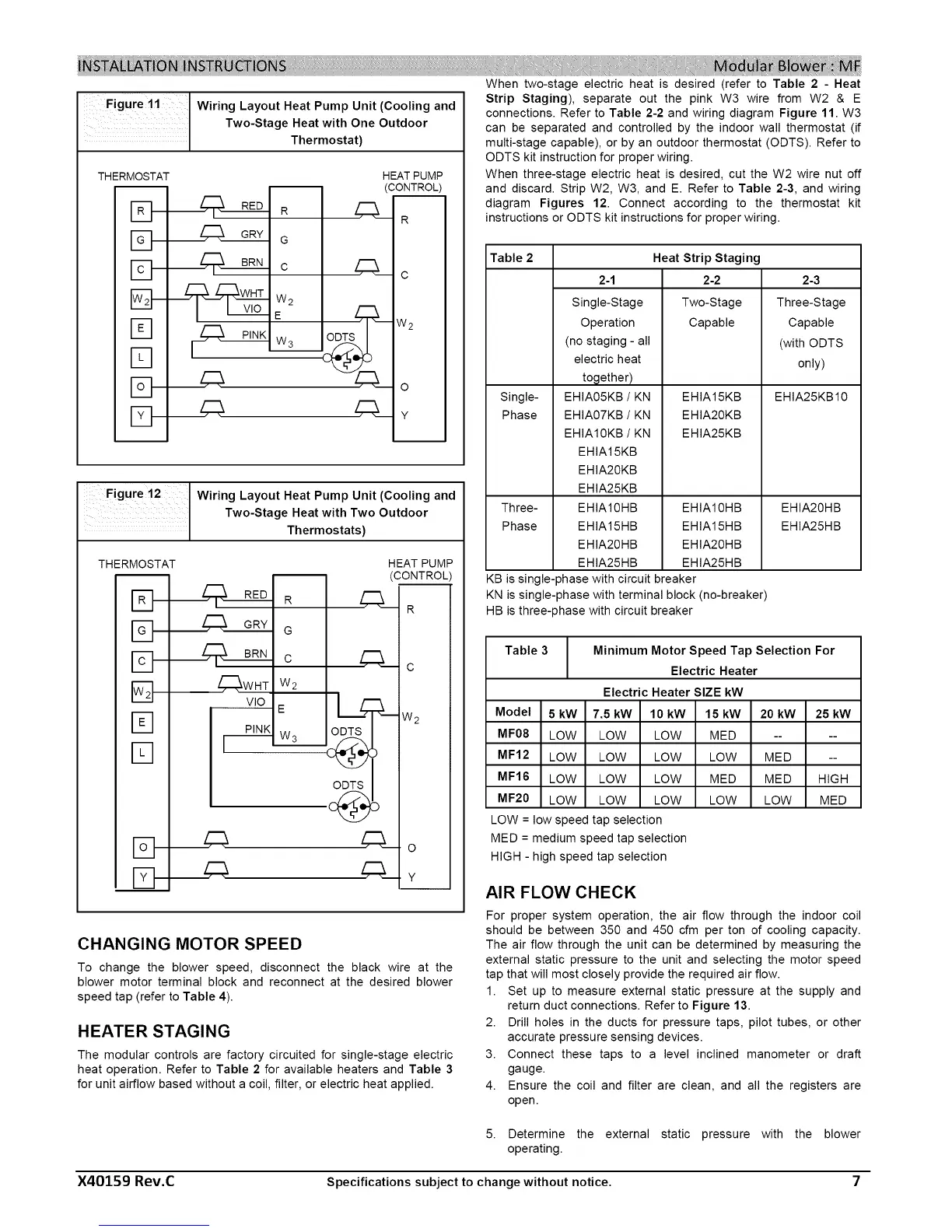

- .-t.igure 1z I Wiring Layout Heat Pump Unit (Cooling and

1

Two-Stage Heat with Two Outdoor

Thermostats)

THERMOSTAT

m

D-

%

Fq

_WHT

VlO

PINK

m

R

G

C

W2

E

w3.....2.__

HEAT PUMP

(CONTROL)

4Q_ R

L __c

o Lw2

ODTS

£___y

CHANGING MOTOR SPEED

To change the blower speed, disconnect the black wire at the

blower motor terminal block and reconnect at the desired blower

speed tap (refer to Table 4).

HEATER STAGING

The modular controls are factory circuited for single-stage electric

heat operation. Refer to Table 2 for available heaters and Table 3

for unit airflow based without a coil, filter, or electric heat applied.

When two-stage electric heat is desired (refer to Table 2 - Heat

Strip Staging), separate out the pink W3 wire from W2 & E

connections. Refer to Table 2-2 and wiring diagram Figure 11. W3

can be separated and controlled by the indoor wall thermostat (if

multi-stage capable), or by an outdoor thermostat (ODTS). Refer to

ODTS kit instruction for proper wiring.

When three-stage electric heat is desired, cut the W2 wire nut off

and discard. Strip W2, W3, and E. Refer to Table 2-3, and wiring

diagram Figures 12. Connect according to the thermostat kit

instructions or ODTS kit instructions for proper wiring.

Table 2 Heat Strip Staging

2-1 2-2

Single-Stage Two-Stage

Operation Capable

(no staging - all

electric heat

Single- EHIA05KB / KN EHIA15KB

Phase EHIA07KB / KN EHIA20KB

EHIA10KB / KN EHIA25KB

EHIA15KB

EHIA20KB

EHIA25KB

Three- EHIA10HB EHIA10HB

Phase EHIA15HB EHIA15HB

EHIA20HB EHIA20HB

EHIA25HB EHIA25HB

KB is single-phase with circuit breaker

KN is single-phase with terminal block (no-breaker)

HB is three-phase with circuit breaker

2-3

Three-Stage

Capable

(with ODTS

only)

EHIA25KB10

EHIA20HB

EHIA25HB

Table 3 Minimum Motor Speed Tap Selection For

Electric Heater

Electric Heater SIZE kW

Model 5 kW 7.5 kW 10 kW 15 kW 20 kW 25 kW

MF08 LOW LOW LOW MED ....

MF12 LOW LOW LOW LOW MED --

MF16 LOW LOW LOW MED MED HIGH

MF20 LOW LOW LOW LOW LOW MED

LOW = low speed tap selection

MED = medium speed tap selection

HIGH - high speed tap selection

AIR FLOW CHECK

For proper system operation, the air flow through the indoor coil

should be between 350 and 450 cfm per ton of cooling capacity.

The air flow through the unit can be determined by measuring the

external static pressure to the unit and selecting the motor speed

tap that will most closely provide the required air flow.

1. Set up to measure external static pressure at the supply and

return duct connections. Refer to Figure 13.

2. Drill holes in the ducts for pressure taps, pilot tubes, or other

accurate pressure sensing devices.

3. Connect these taps to a level inclined manometer or draft

gauge.

4. Ensure the coil and filter are clean, and all the registers are

open.

5. Determine the external static pressure with the blower

operating.

X40159 Rev.C Specifications subject to change without notice. 7

Loading...

Loading...