SHOULD NOT be in contact with any part of the structure. Check Installation

local codes covering zoning, noise, platforms, etc..

Avoid locating next to fresh air intakes, vent or bedroom windows.

Noise may carry into the openings and disturb people inside.

Avoid installations under roof overhangs without guttering. Water

draining from the roof onto the unit could produce excessive

noise, and may cause ice to build up on coil or fan.

Placement of the unit should be in a well drained area or the unit

MUST be supported high enough so runoff will not enter the unit.

Do not locate unit where heat, lint or exhaust fumes wil! be

discharged on unit (as from dryer vents.)

Clearances

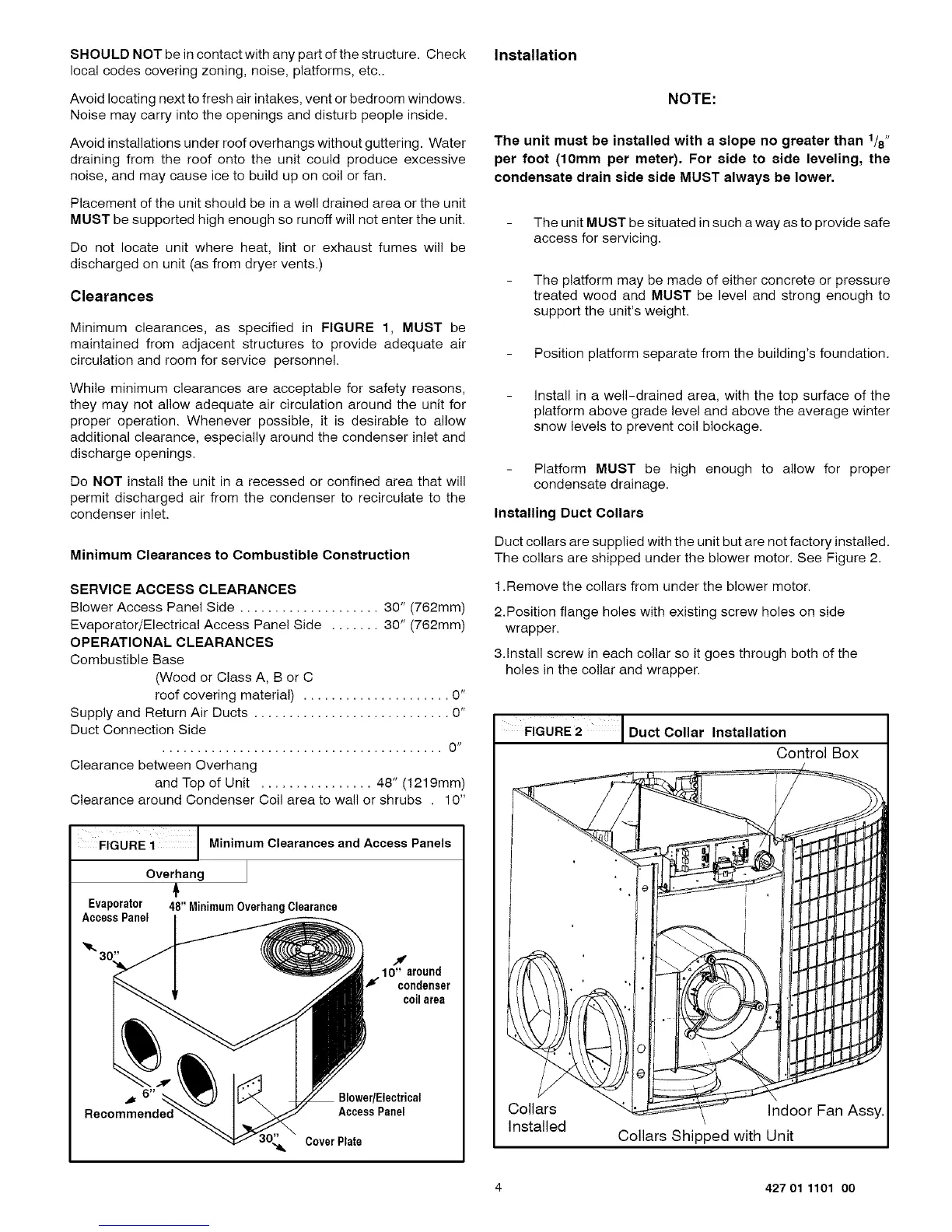

Minimum clearances, as specified in FIGURE 1, MUST be

maintained from adjacent structures to provide adequate air

circulation and room for service personnel.

While minimum clearances are acceptable for safety reasons,

they may not allow adequate air circulation around the unit for

proper operation. Whenever possible, it is desirable to allow

additional clearance, especially around the condenser inlet and

discharge openings.

Do NOT install the unit in a recessed or confined area that will

permit discharged air from the condenser to recirculate to the

condenser inlet.

Minimum Clearances to Combustible Construction

SERVICE ACCESS CLEARANCES

Blower Access Panel Side .................... 30" (762mm)

Evaporator/Electrical Access Panel Side ....... 30" (762mm)

OPERATIONAL CLEARANCES

Combustible Base

(Wood or Class A, B or C

roof covering material) ..................... 0"

Supply and Return Air Ducts ............................ 0"

Duct Connection Side

........................................ 0 sl

Clearance between Overhang

and Top of Unit ................ 48" (1219mm)

Clearance around Condenser Coil area to wall or shrubs . 10"

FIGURE i Minimum Clearances and Access Panels

Overhang

Evaporator 48" MinimumOverhangClearance

AccessPanel

10" around

f condenser

coilarea

BlowedElectrical

AccessPanel

CoverPlate

NOTE:

The unit must be installed with a slope no greater than 1/8"

per foot (10mm per meter). For side to side leveling, the

condensate drain side side MUST always be lower.

The unit MUST be situated in such a way as to provide safe

access for servicing.

The platform may be made of either concrete or pressure

treated wood and MUST be level and strong enough to

support the unit's weight.

Position platform separate from the building's foundation.

install in a well-drained area, with the top surface of the

platform above grade level and above the average winter

snow levels to prevent coil blockage.

Platform MUST be high enough to allow for proper

condensate drainage.

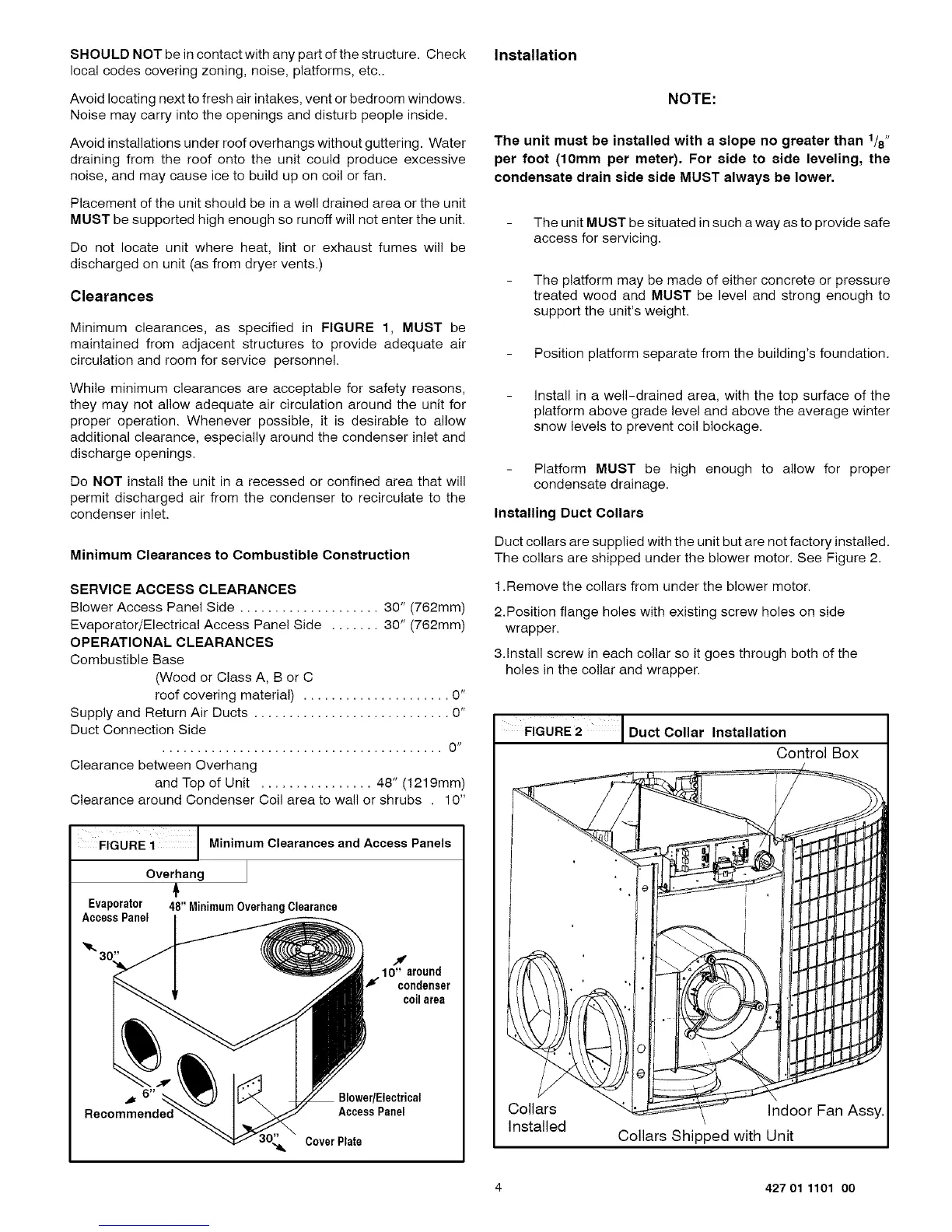

Installing Duct Collars

Duct collars are supplied with the unit but are not factory installed.

The collars are shipped under the blower motor. See Figure 2.

1.Remove the collars from under the blower motor.

2.Position flange holes with existing screw holes on side

wrapper.

3.Install screw in each collar so it goes through both of the

holes in the collar and wrapper.

FIGURE2 I Duct Collar Installation

Control Box

Collars

Installed

Indoor Fan Assy.

Collars Shipped with Unit

4 427 01 1101 00

Loading...

Loading...