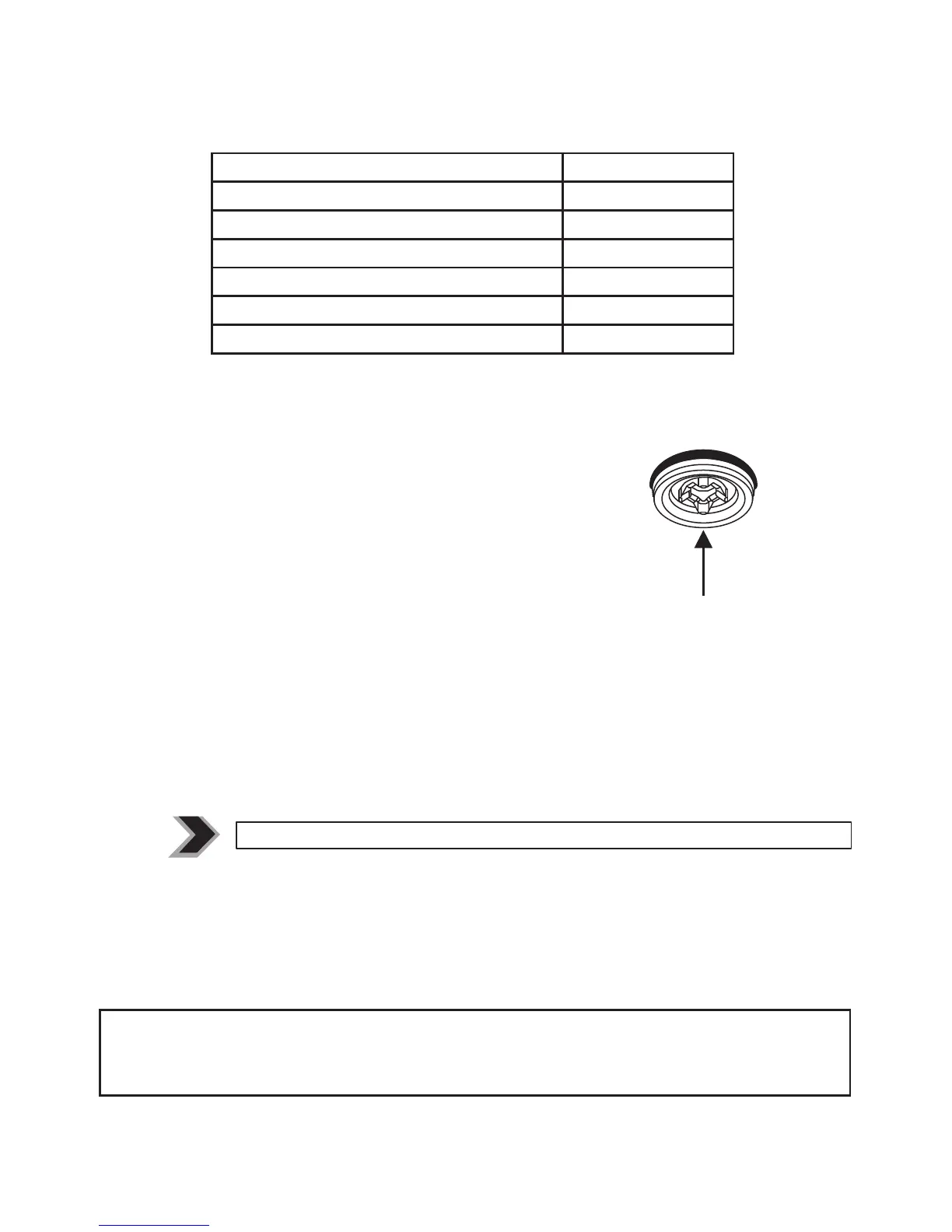

Table 1 Conditions of use for Type 2 valves

7

MODULATING COMBI BOILER

This thermostatic shower valve is designed for use with modulating

combination boilers.

When installing on a modulating combination boiler it is sometimes

possible for the interaction of a thermostatic valve with the combi to

cause the boiler to cut out and cut in again, with the result that the

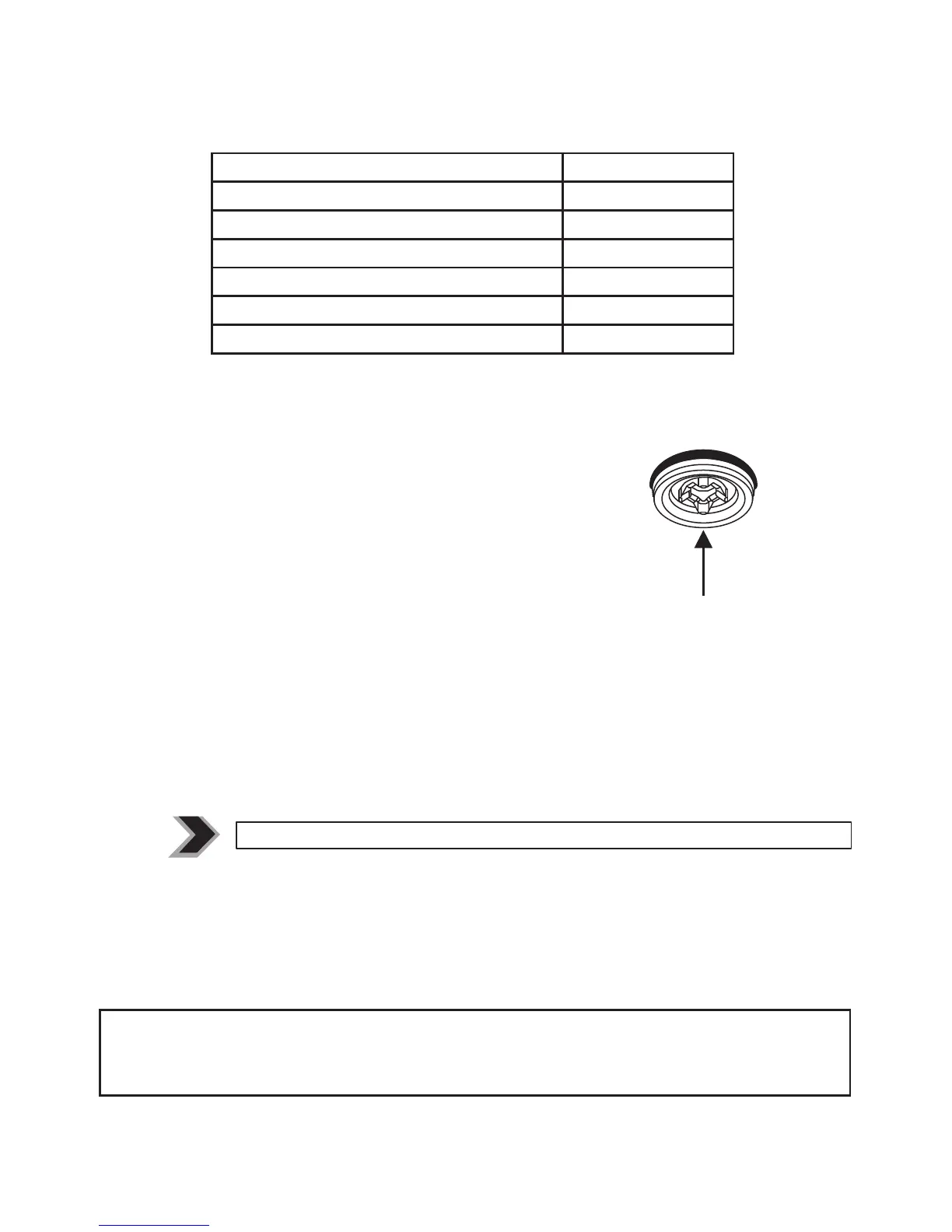

water will become alternatively cold and hot. To overcome this, a 4 L/min

ow regulator should be tted upstream of the thermostatic valve.

It should be tted in any 15mm compression tting in the dedicated cold supply pipe.

It is important to choose a compression tting located in a position which is accessible after installation

and it must be tted the correct way round for the direction of ow. The regulator can be tted in either

the inlet or outlet side of the compression tting. If tting in an outlet side, ensure the o-ring is seated

fully in the visible rebate around the edge of the regulator. Use the tip of a small screwdriver or similar

to achieve this. Ensure the tail of the pipe is not fouling the regulator (shorten if required) and do up

the compression tting as normal. In a minority of cases, where the boiler is of a type which stores a

small quantity of very hot water, it may also be necessary to t a 4 l/min ow regulator in the hot supply.

flow direction

through

flow regulator

Isolation valves MUST be tted to permit future maintenance of these products.

See sect 12 for more details.

Check valves are included with this product inside the inlets see sect 11.

These regulators (code A962570NU) can be obtained by contacting fastpart:

3 SUPPLY CONDITIONS

For more information on spare parts why not visit our spare website

www.fastpart-spares.co.uk

fast

t r a p

BSEN1111

Operating pressure range: High Pressure

Maximum static pressure 10 bar

Flow pressure hot and cold 0.5 to 5.0 bar

Hot supply temperature 55 to 65 °C

Cold supply temperature 5 to 20 °C

Temperature differential characteristic (TDC) 10 °C

Loading...

Loading...