TFC Group Ltd. Tel. + 44 (0) 01732 351 680

Tower House, Vale Rise Fax. +44(0) 01732 354 445

Tonbridge. kent TN9 1TB www.tfc-group.co.uk

5.

ignition or damage to any part of any building.

6. The air inlet/products outlet duct and the terminal of the

boiler MUST NOT be closer than 25mm (1”) to combustible

IMPORTANT. It is essential to ensure, in practice, that products

of combustion discharging from the terminal cannot re-enter the

building or buildings through any openings into the building such

as ventilators, windows, doors, or other sources of natural air

be immediately investigated and corrected following the guidance

provided in the current Gas Industry Unsafe Situation Procedure.

WATER CIRCULATION SYSTEM

IMPORTANT.

connection to any plastic piping.

and return pipework should be connected in 28mm pipe.

For the types of system and correct piping procedure see Frames

1, and 3 to 8.

The central heating system should be in accordance with BS.6798

and, in addition, for smallbore and microbore systems, BS.5449.

WATER TREATMENT - see Frame 9

The hot water storage cylinder MUST be of the indirect type and

should preferably be manufactured of copper.

Single feed, indirect cylinders are not recommended and MUST

NOT be used on sealed systems.

The appliances are NOT suitable for gravity central heating nor

are they suitable for the provision of gravity domestic hot water.

The hot water cylinder and ancillary pipework, not forming part of

the useful heating surface, should be lagged to prevent heat loss

and any possible freezing - particularly where pipes run through

The boiler must be vented.

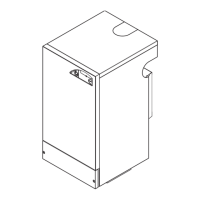

The hydraulic resistance of the boilers, at MAXIMUM OUTPUT, is

shown in Graph 1.

BOILER CONTROL INTERLOCKS

Ideal Boilers recommend that heating systems utilising full

thermostatic radiator valve control of temperature in individual

valve as stated in BS. 5449.

Central heating systems controls should be installed to ensure the

boiler is switched off when there is no demand for heating or hot

water.

When thermostatic radiator valves are used, the space heating

temperature control over a living / dining area or hallway having

should be achieved using a room thermostat, whilst other rooms

are individually controlled by thermostatic radiator valves.

However, if the system employs thermostatic radiator valves on all

radiators, or two port valves without end switches, then a bypass

Graph 1 - Water ow rate and pressure loss

TERMINAL

The terminal assembly can be adapted to accommodate various

wall thicknesses. Refer to Frame 19.

AIR SUPPLY

It is NOT necessary to have a purpose-provided air vent in the

room or internal space in which the boiler is installed. Neither

is it necessary to ventilate a cupboard or compartment in which

the boiler is installed, due to the low surface temperatures of the

boiler casing during operation; therefore the requirements of BS

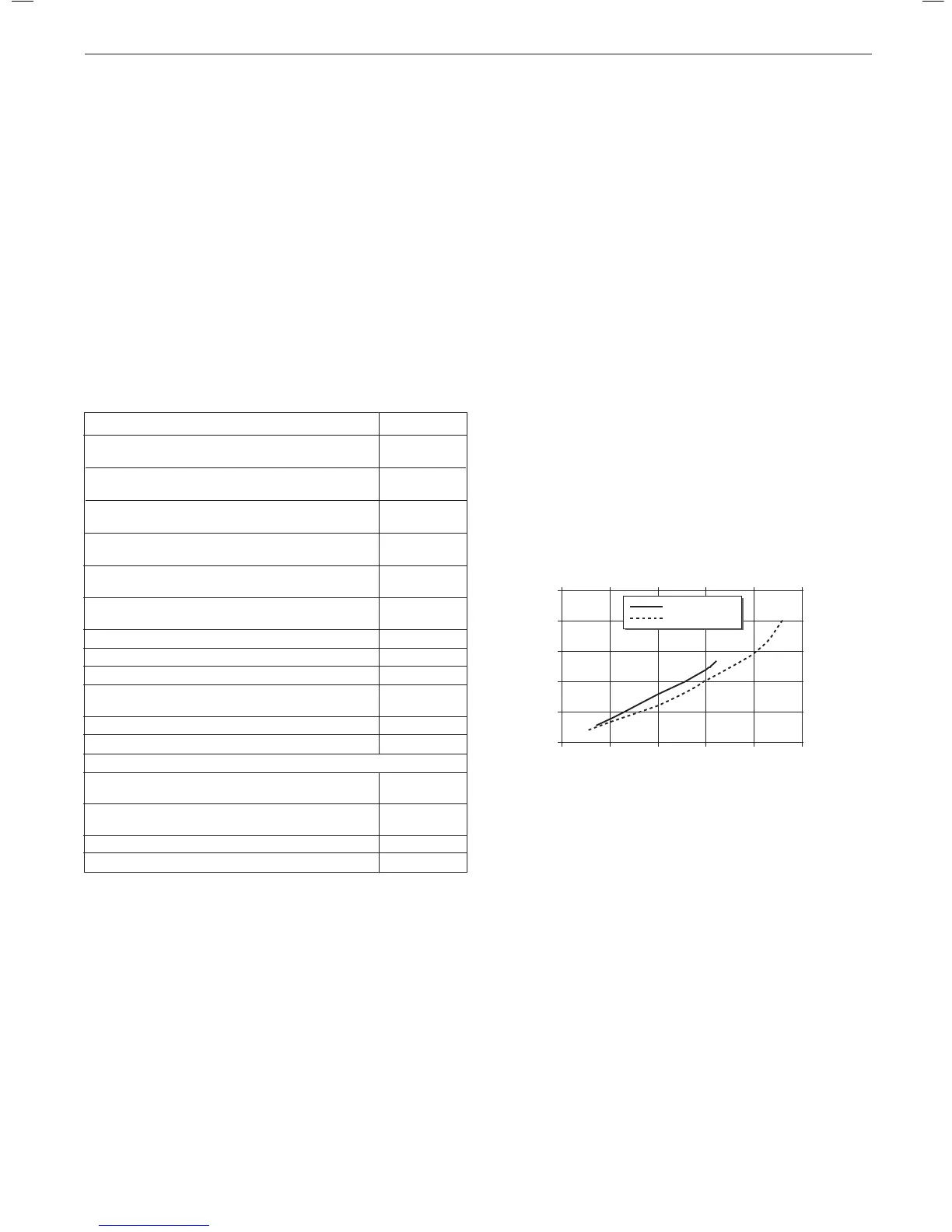

Flue Terminal Positions

Min. Spacing*

1.

window, air vent or other ventilation opening. 300mm (12”)

2.

BS5440-1 2008 75mm (3”)

3.

BS5440-1 2008 200mm (8”)

4.

BS5440-1 2008 200mm (8”)

5.

BS5440-1 2008 150mm (6”)

6.

boundary along side the terminal. BS5440-1 2008 300mm (12”)

7. Above adjacent ground, roof or balcony level. 300mm (12”)

8. From a surface or a boundary facing the terminal. 600mm (24”)

9. From a terminal facing a terminal. 1,200mm (48”)

10. From an opening in a car port

(e.g. door or window) into dwelling. 1,200mm (48”)

11. Vertically from a terminal on the same wall. 1,500mm (60”)

12. Horizontally from a terminal on the wall. 300mm (12”)

Vertical Terminals

13. Above the roof pitch with roof slope of all angles. 300mm (12”)

14. From a single wall face. 600mm (24”)

From corner walls. 1000mm (40”)

15. Below Velux Window 2000mm (79”)

16. Above or side of velux window 600mm (24”)

Table 3 - Balanced Flue Terminal Position

* Only one reduction down to 25mm is allowable per installation

otherwise BS5440-1 2008 dimensions must be followed.

Loading...

Loading...