LOCATION OF BOILER

adequately supporting the weight of the boiler and any ancillary

equipment.

necessary, unless required by the local authority.

For electrical safety reasons there must be no access from the

back of the boiler.

The boiler must not be tted outside.

Timber Framed Buildings

Bathroom Installations

This appliance is rated IP20.

The boiler may be installed in any room or internal space,

although particular attention is drawn to the requirements of

provisions of the building regulations applicable in Scotland,

with respect to the installation of the boiler in a room or internal

If the appliance is to be installed in a room containing a bath or

shower then, providing water jets are not going to be used for

cleaning purposes (as in communal baths/showers), the appliance

must be installed beyond Zone 2, as detailed in BS.7671.

Compartment Installations

A compartment used to enclose the boiler should be designed and

constructed specially for this purpose.

An existing cupboard or compartment may be used, provided that

In both cases details of essential features of cupboard /

compartment design, including airing cupboard installation, are to

BS. 6798. (No cupboard ventilation is required - see “Air

Supply” for details).

The position selected for installation MUST allow adequate

space for servicing in front of the boiler.

For the minimum clearances required for safety and

subsequent service see Frame 2.

This position MUST also permit the provision of a satisfactory

ventilation.

GAS SUPPLY

The local gas supplier should be consulted, at the installation

planning stage, in order to establish the availability of an adequate

supply of gas. An existing service pipe must NOT be used without

prior consultation with the local gas supplier.

The boiler MUST be installed on a gas supply with a governed

meter only.

A gas meter can only be connected by the local gas supplier or

Installer (RGII).

An existing meter should be checked, preferably by the gas

supplier, to ensure that the meter is adequate to deal with the rate

of gas supply required.

It is the responsibility of the Gas Installer to size the gas installation

deliver it’s full output at inlet pressures as low as 14mb, other gas

appliances in the property may not be as tolerant. When operating

pressures are found to be below the minimum meter outlet of 19mb

these should be checked to ensure this is adequate for correct and

safe operation.

Allowing for the acceptable pressure loss of 1mb across the

installation pipework, it can be assumed that a minimum permitted

operating pressure of 18mb will be delivered to the inlet of

the appliance. (Reference BS 6400-1 Clause 6.2 Pressure

Absorption).

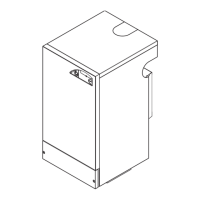

The external gas cock could further reduce the operating pressure

when measured at its test point. The pressure drop is relative to

the heat input to the boiler (kW), refer to graph below.

IMPORTANT.

MUST be of an adequate size, i.e. no longer than 20m and not less

The complete installation MUST be tested for gas tightness and

purged as described in the above code.

FLUE INSTALLATION

Pluming will occur at the terminal so terminal positions which would

cause a nuisance should be avoided.

The following notes are intended for general guidance.

1. The boiler MUST be installed so that the terminal is exposed to

external air.

2. It is important that the position of the terminal allows the free

passage of air across it at all times.

3. Minimum acceptable spacing from the terminal to obstructions

4.

to which people have access, then the terminal MUST be

Terminal guards are available from boiler suppliers. Ask for TFC

Loading...

Loading...