17

INSTALLATION

icos system - Installation and Servicing

FLUE OUTLET

Notes.

1. It is recommended that a support bracket is fitted for

every 1 meter of extension pipe used and a bracket

should be used at every joint, to ensure pipes are held at

the correct angle.

If a slip joint coupling is to be used then a bracket

should be used to secure the collar.

2. When extension ‘D’ packs are used the flue duct MUST

be inclined at 1.5 degrees to the horizontal to allow

condensate to drain back into the boiler and out through

the condensate drain.

3. If the telescopic ‘B’ pack, or horizontal flue terminal (600

long) only are used, they may be mounted horizontally.

The 1.5 degreesis taken care of by the inclination of the

flue within the air pipe.

4. If the boiler is to be installed with upward piping routed

behind the boiler then the optional stand-off kit should

be used. Care must be taken when cutting the ducts and

marking the wall to suit this condition.

5. Only use water as a lubricant during assembly. Do not

use mineral based oils.

12A

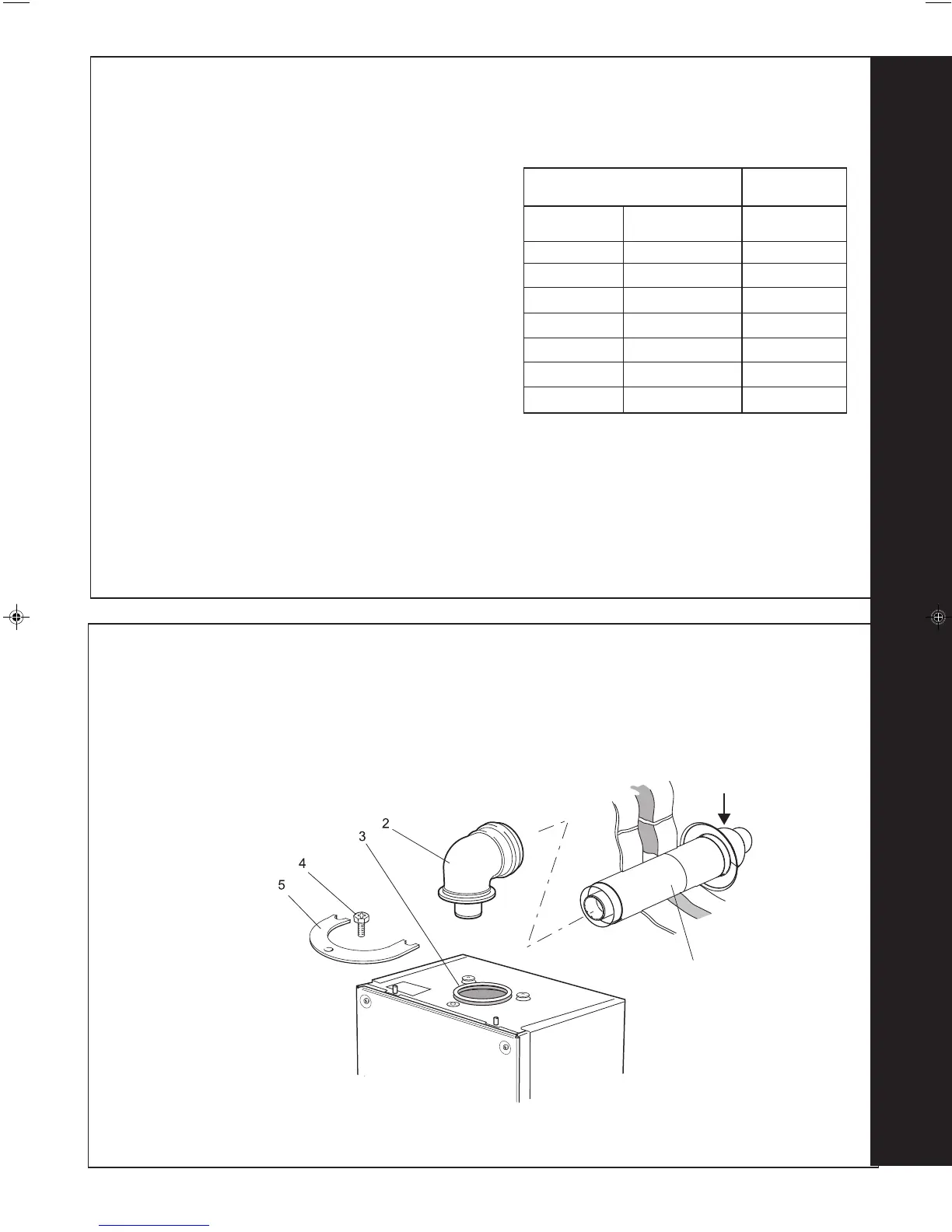

DETERMINING THE FLUE LENGTH AND FLUE PACKS REQUIRED, CONT'D

Total Flue length dimension Flue

(measuring from CL of turret to outside wall)

Rear flue Side flue Extra packs

dim. X+160 dim. L+195 required

Up to 595 mm Up to 595 mm none

Up to 1545 mm Up to 1545 mm Pack D - 1 off

Up to 2495 mm Up to 2495 mm Pack D - 2 off

Up to 3445 mm Up to 3445 mm Pack D - 3 off

Up to 4395 mm Up to 4395 mm Pack D - 4 off

Up to 5345 mm Up to 5345 mm Pack D - 5 off

Up to 6000 mm Up to 6000 mm Pack D - 6 off

1

nm8760

13

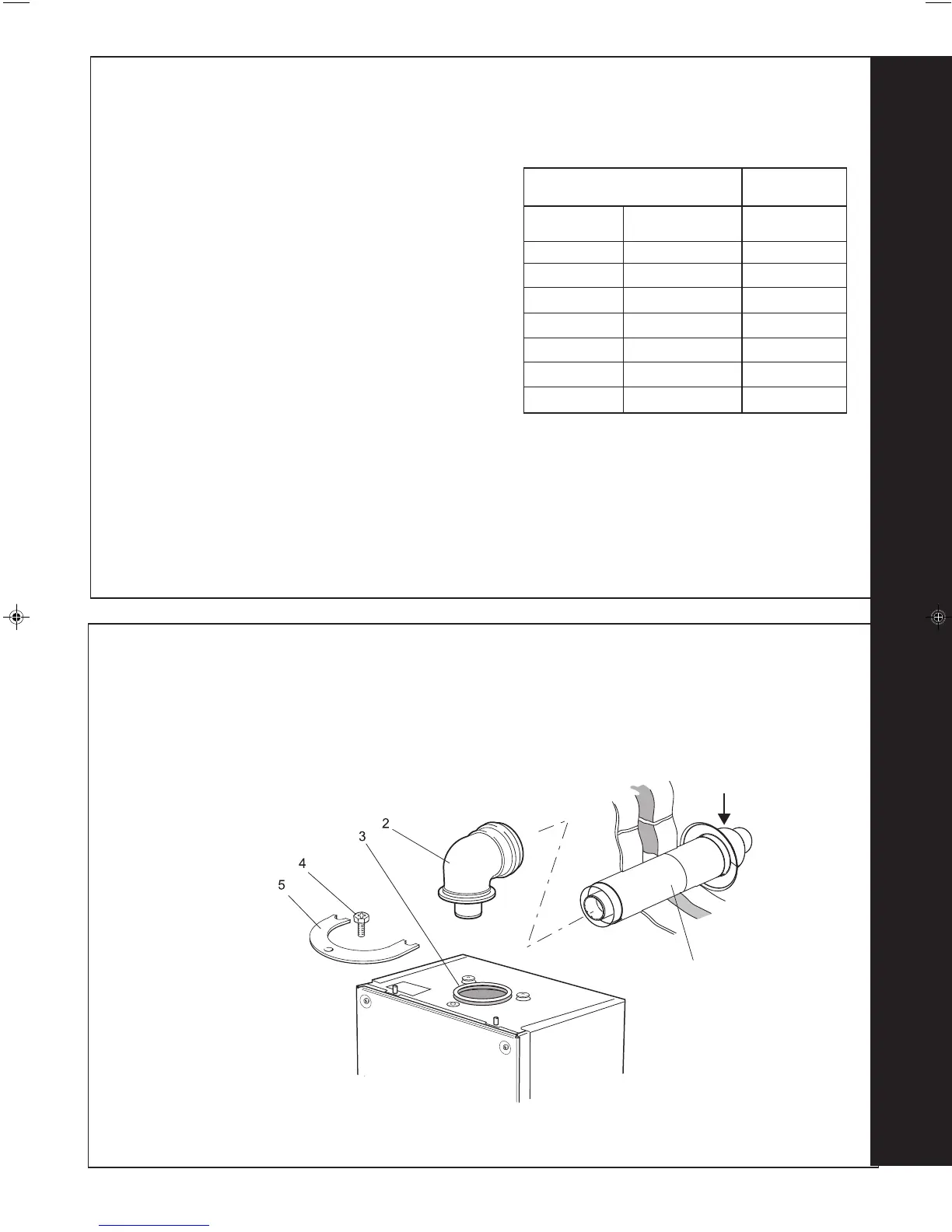

FLUE ASSEMBLY - Exploded View

An optional flue duct extension kit is

required for wall thicknesses greater

than :

Side 395mm

Rear 435mm

Rear flue arrangement shown

LEGEND

1. Duct assembly.

2. Flue Turret.

3. Turret gasket.

4. M5 x 10 pozi screw.

5. Turret clamp.

The flue terminal MUST be

fitted with the ‘TOP’

uppermost to allow the

correct fit and use of the

plume management system.

TOP

Loading...

Loading...