Engineering

44

HR9Z-B2192 8/2020

Signal Interlock Monitoring

Overview

Signal interlock is a monitoring function used to detect conditions in which one of the

sensors/devices cannot provide the expected input signal for the device, for example, as a result

of contact welding.

The device expects “simultaneous” deactivation of the two safety-related inputs within the signal

interlock monitoring time of 200 ms.

If the two monitored safety-related inputs are not deactivated within 200 ms, this is a signal

interlock condition and the device triggers a signal interlock alert. The device remains in the defined

safe state, i.e., there is no transition from operating state Run: Outputs Deenergized to operating

state Run: Outputs Energized (T3).

To exit the signal interlock condition, the two affected safety-related inputs must be deactivated for

at least one second. After that, the safety-related inputs can be activated again which activates the

safety-related outputs as well.

Signal interlock is available for certain of the application functions

(see page 58)

the device

provides.

Examples

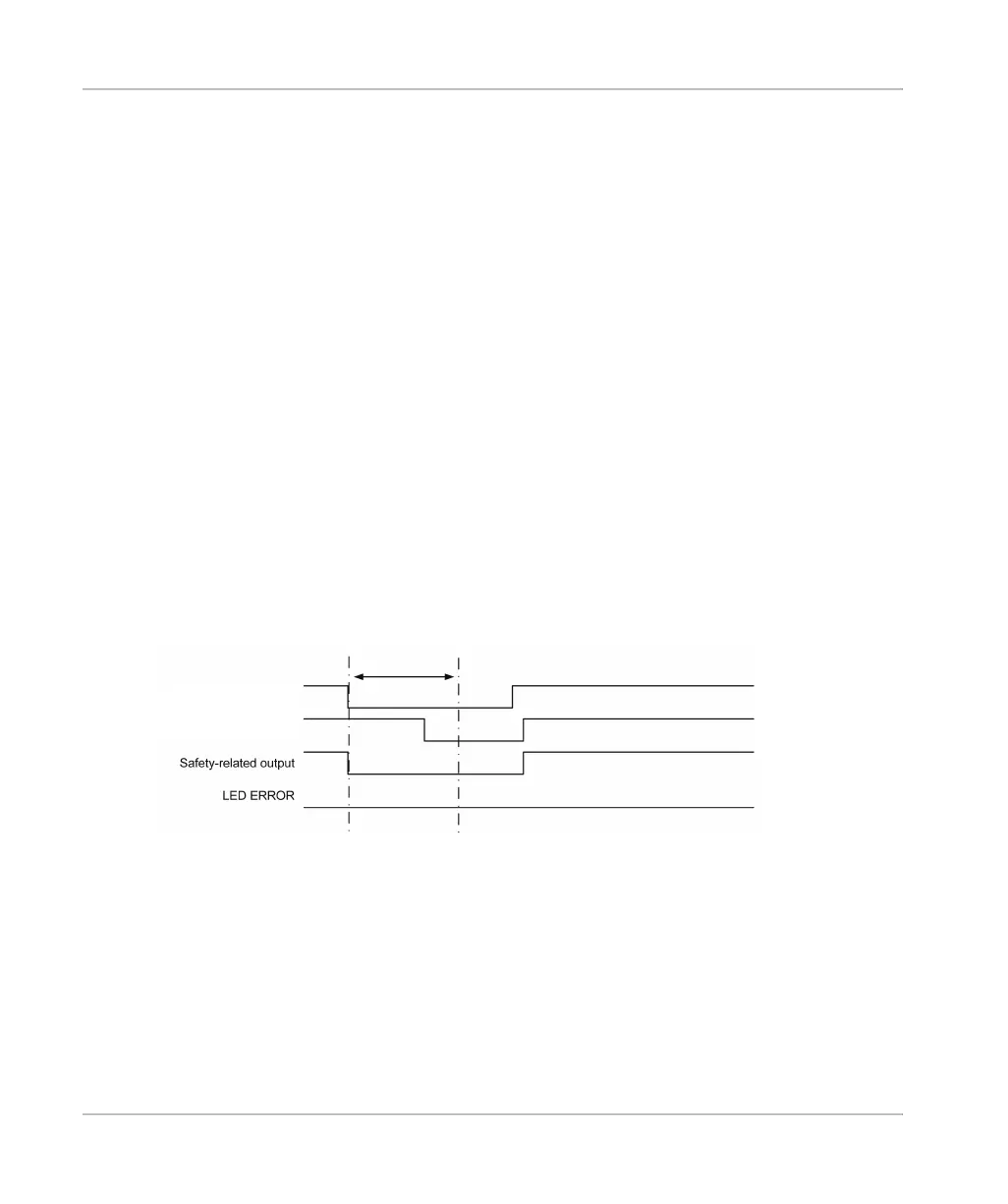

The following figure illustrates a condition without signal interlock:

Both safety-related inputs are deactivated within the signal interlock monitoring time of 200 ms.

When they are activated again, the safety-related outputs are also activated.

Safety-relaed input S##

Safety-relaed input S##

Loading...

Loading...