20

Interfaces and outputs

NOTE

Please comply with the system re-

quirements together with the op-

erating instructions and help sec-

tion included with the software.

The device can be operated in “Remote” mode via an RS232 or

USB interface using the laboratory software labworldsoft

®

. The RS

232 interface (M) at the back of the device is fitted with a 9-pole

SUB-D jack which can be connected to a PC. The pins are assigned

serial signals.

USB Interface

The Universal Serial Bus (USB) is a serial bus system which allows

the device to be connected to the PC. Devices that support USB

can be connected to each other whilst they are running (hot plug-

ging) and provide automatic recognition of the connected devices

and their properties.

Use the USB interface in conjunction with labworldsoft® for oper-

ation in “Remote” mode and for updating the firmware using the

“Firmware update tool”.

Installation

Before the device is connected with the PC using the USB data

cable, the USB driver must be installed.

The USB driver can be downloaded from the website.

Serial interface RS 232 (V 24)

Configuration:

• The functions of the interface circuit between the dev ice

and the automation system are a selection from the signals

specified in the EIA standard RS232 as per DIN 66020 Part 1.

• Standard RS 232, corresponding to DIN 66259 Part 1 is valid

for the electric characteristics of the interface circuits and as-

signment of signal states.

• Transmission process: Asynchronous character transmission

in start-stop operation.

• Transmission type: Full duplex.

• Character format: Character composition according to data

format in DIN 66022 for start-stop operation. 1 start bit, 7

character bits, 1 parity bit (even), 1 stop bit.

• Transmission speed: 9600 Bits/s.

• Data flow control: none

• Access method: Data transmission from the device to the

computer only occurs after a request from the computer.

Command syntax and format

The following points should be noted for the instruction set:

• Commands are generally sent from the computer (master) to

the device (slave).

• The device only responds to requests from the computer.

Even error messages are not send spontaneously from the

device to the computer (automation system).

• The commands are transmitted in captial letters.

• Commands and parameters, as well as consecutive parame-

ters, must be separated by at least one space (code: hex 0x20

).

• Each individual command (including parameters and data)

and all responses are completed with CRLF (code: hex 0x20

hex 0x0d hex 0x0A) and can have a maximum length of 50

characters.

• The dot is used for decimal separators in a floating-point val-

ue (code: hex 0x2E).

The details given above generally comply with the recommen-

dations of NAMUR (NAMUR recommendations for the design of

electrical plug-in connectors for analogue and digital signals in

laboratory MSR devices. Rev. 1.1).

The NAMUR commands and the additional IKA specific commands

are only used as low-level commands for communication between the

device and the PC. With an appropriate terminal or communication

program, these commands can be transmitted directly to the device.

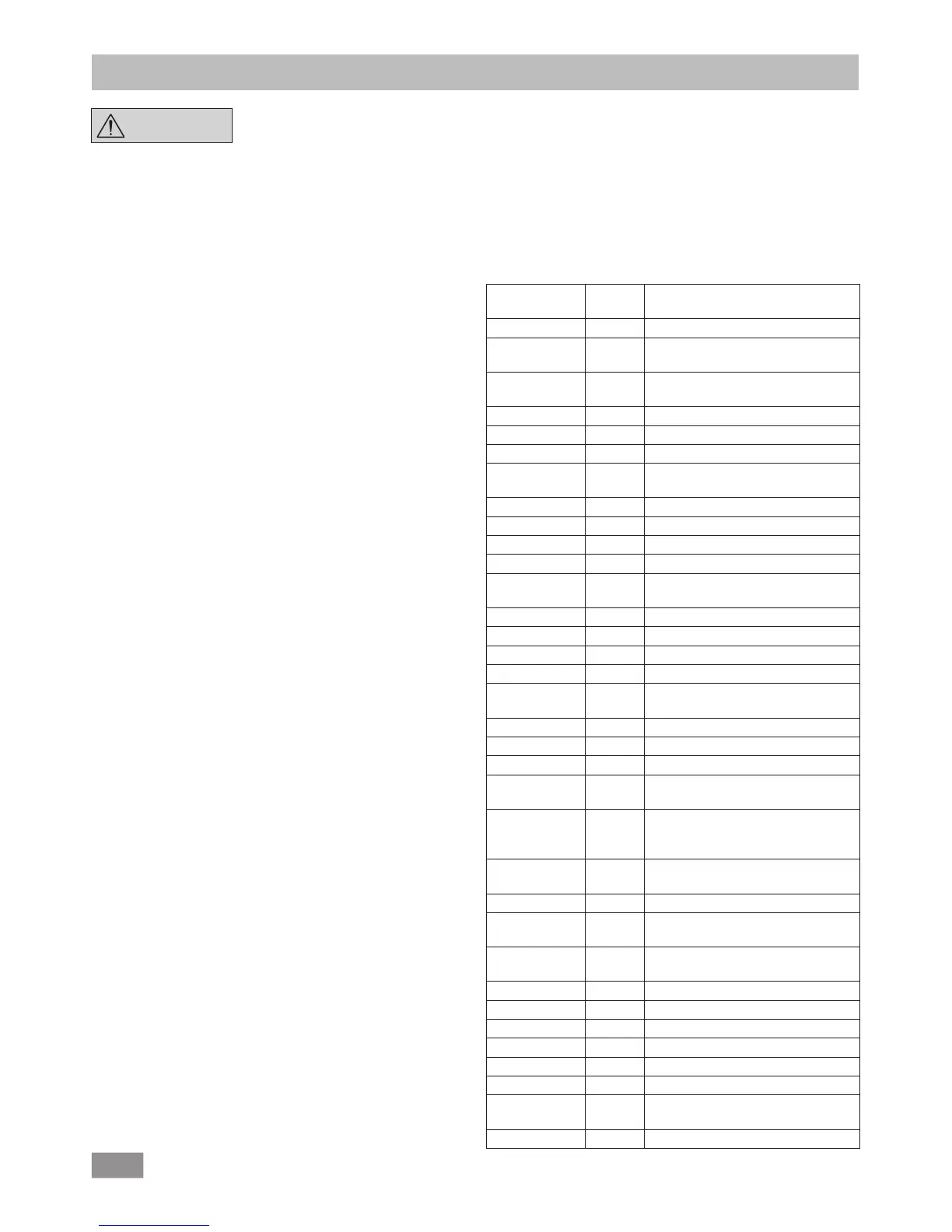

NAMUR commands Function

Command

Firmware

Version

Description

IN_PARA1 0.0.020 Return the actual values

OUT_PARA1 0.0.020 Set the set values for the pump

control

OUT_PARA2 0.0.020 Set the set values for Bluetooth

connection

OUT_STATUS 0.0.020 Send the actual device status

IN_STATUS 0.0.020 Reads the status of a device

IN_VERSION 0.0.020 Read the version of the firmware

IN_DATE 0.0.020 Read the release date of the display/

logic firmware

IN_NAME 0.0.020 Read the name of the device

IN_DEVICE 0.0.020 Read the device type.

IN_ADDRESS 0.0.020 Read mac address of Wico.

IN_PARING 0.0.020 Read paired mac address of station.

OUT_ADDRESS 0.0.020 Write new paired mac addresses of

both station and Wico.

IN_SP_66 0.0.020 Reads the set pressure value

OUT_SP_66 0.0.020 Sets set point pressure value

IN_PV_66 0.0.020 Reads the actual pressure value

IN_MODE_66 0.0.020 Reads the evacuating mode

OUT_

MODE_66

0.0.020 Sets the evacuating mode

IN_ERROR 0.0.020 Reads error state

OUT_ERROR 0.0.020 Test Error. Sends out error code

IN_BT_NAME 0.0.020 Reads Bluetooth Device Name

IN_CUSTOM_

DEVICE_NAME

0.0.020 Reads custom device name

OUT_CUS-

TOM_DEVICE_

NAME

0.0.020 Sets custom device name

IN_WD1@ 0.0.020 Reads communication watchdog

time

OUT_WD1@ 0.0.020 Sets communication watchdog time

OUT_WD2@ 0.0.020 Set PC communication watchdog

time 2

OUT_SP_41 n

(0 -100 %)

0.0.020 Set the PC safety pump rate

OUT_SP_42 0.0.020 Set the PC safety pressure

RESET 0.0.020 Switch to normal operating mode

START_66 0.0.020 Starts the measurement

STOP_66 0.0.020 Stops the measurement

ENTER_IAP 0.0.020 Starts IAP mode

CALIB_66 0.0.020 It is used to calibrate vacuum.

IN_CALIB_66 0.0.020 It is used to read vacuum calibration

values

OUT_CALIB_66 0.0.020 It is used to calibrate vacuum.

Loading...

Loading...