9

Assembly and setting up

NOTE

Ensure that you follow the general

rule, that the recipient (load/vacu-

um container/glass condenser)

should always be connected to the

suction line at its highest point.

This reduces the risk of liquids en-

tering the vacuum pump.

Liquid in the pump chambers makes

the pump properties worse.

Connect the hose connections (IN-

LET/OUTLET) and interfaces in ac-

cordance with the labelling on the

pump and the operating instruc-

tions.

The connections are barbed hose connectors. Ensure that the hos-

es have hose clips if applicable.

Lay the hoses in such a way that no condensate can flow into the

pump.

Ensure that the air can enter the ventilation slit (Fig. 2, 6) unhin-

dered.

Install a condensate separator (e.g. a VSW 1 in the suction line

before the intake spigot of the pump to protect against water

coming in.

If solvent vapours are sucked in, the emission condenser after the

pump helps to condense it, and prevents it being released into the

atmosphere.

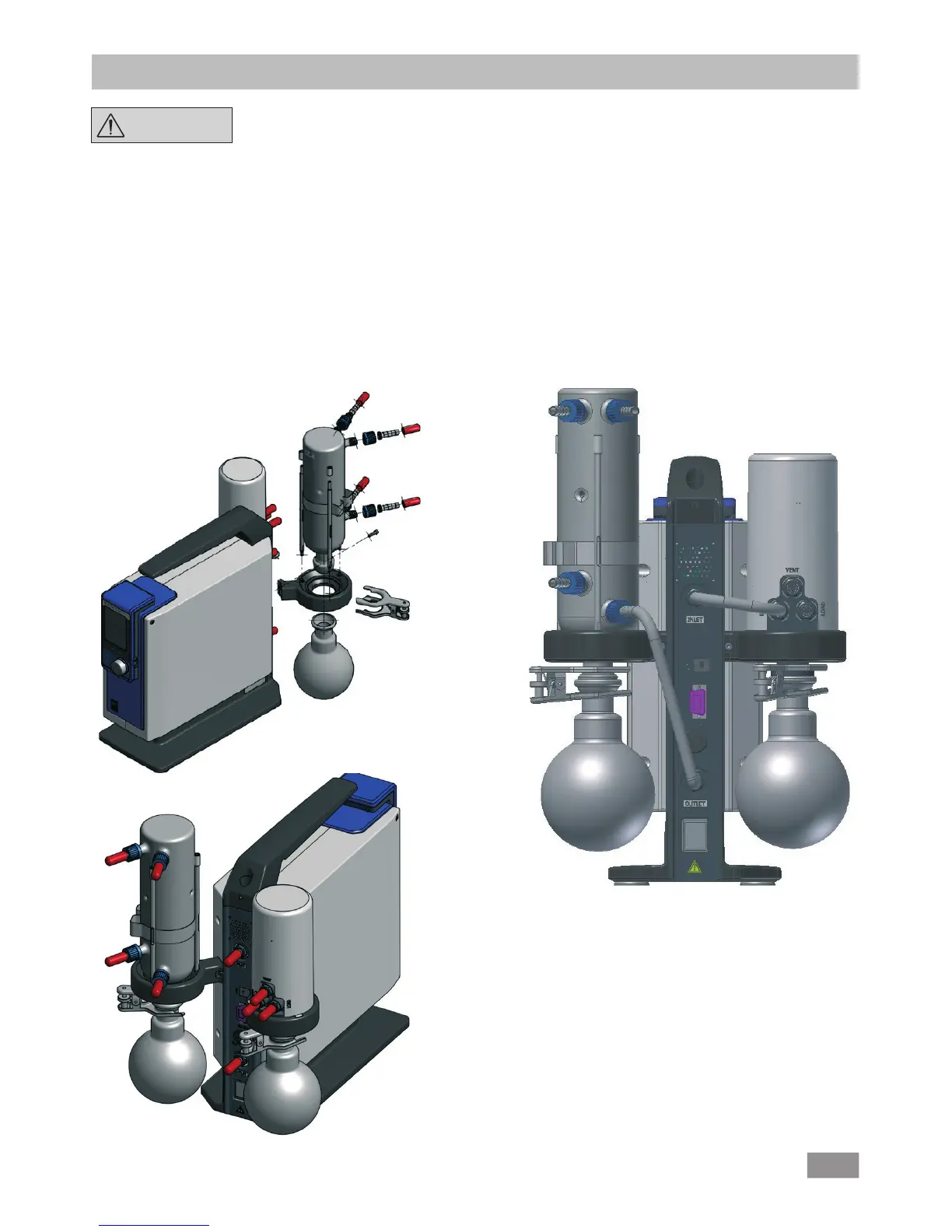

Fig. 4

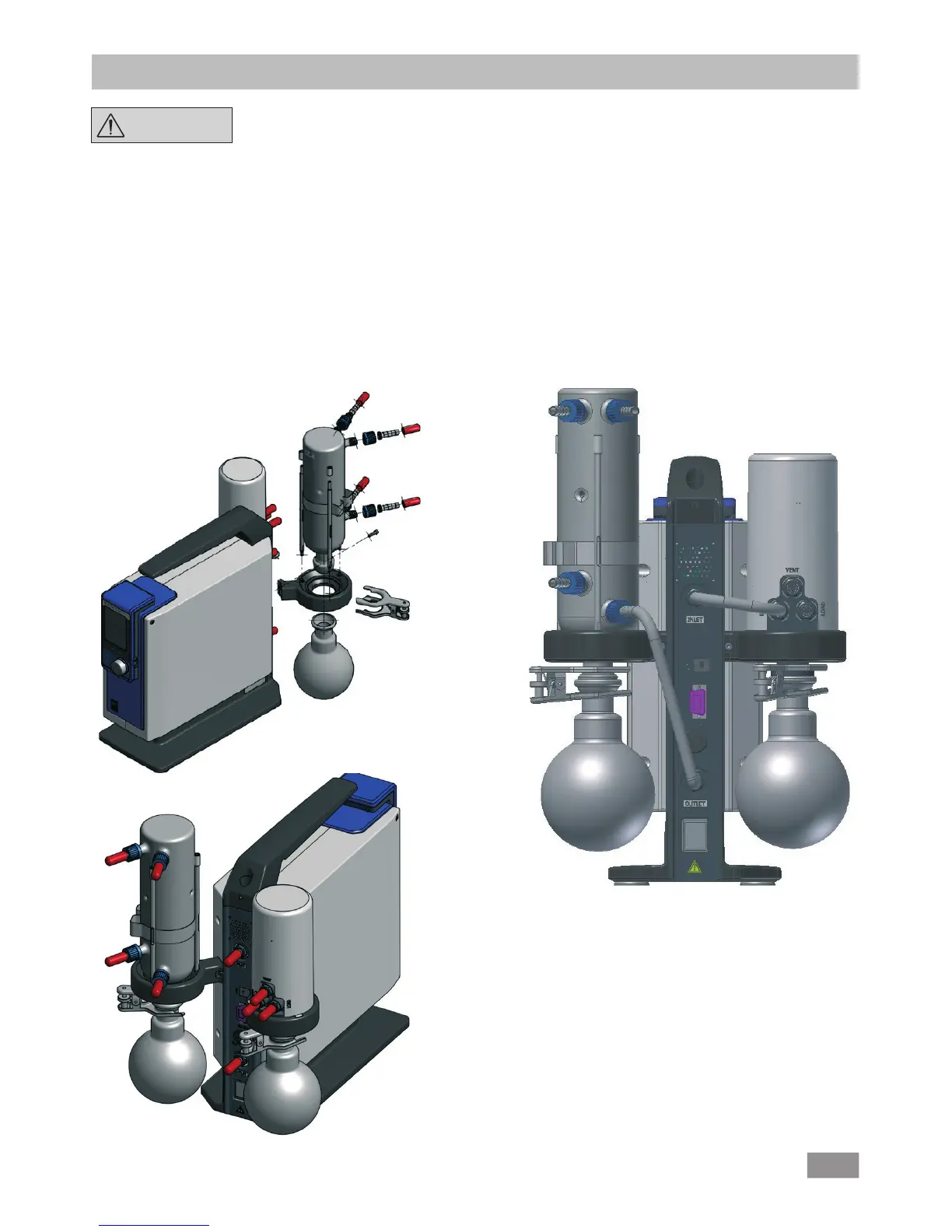

Fig. 5

Fig. 3

Water in

Water out

Loading...

Loading...