29

3-19

45

31

58

3-20

INSTALLERUSER

MAINTENANCE TECHNICIAN

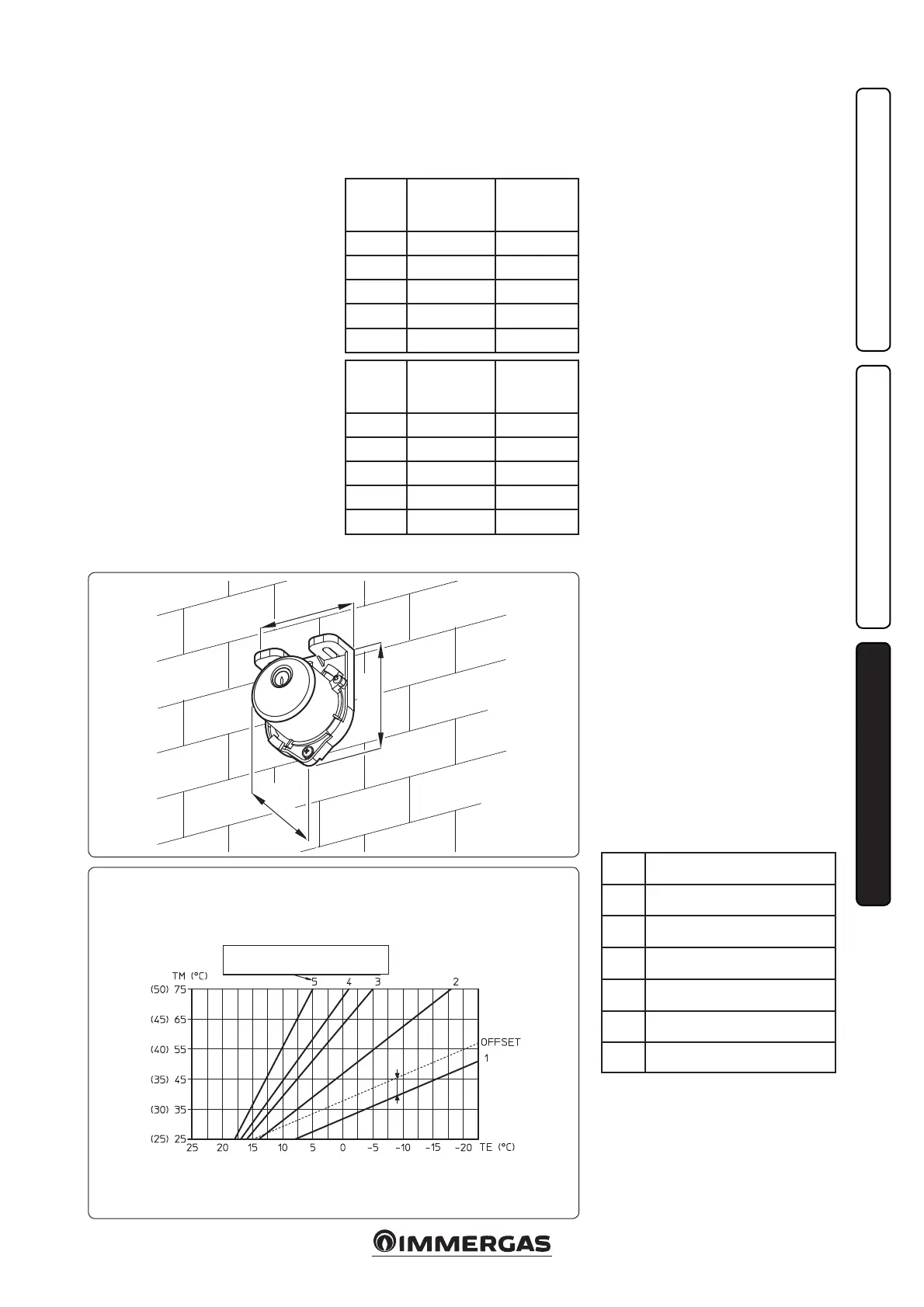

3.14 EXTERNAL TEMPERATURE PROBE

OPTIONAL.

e manifold is designed for the application of

the external probe (Fig. 3-19), which is available

as an optional kit. e probe can be connected

directly to the manifold P.C.B. or to the boiler

electrical system and allows the max. system

ow temperature to be automatically decreased

when the external temperature increases, in

order to adjust the heat supplied to the system

according to the change in external tempera-

ture. e external probe always operates when

connected, regardless of the presence or type of

room chrono-thermostat used, and can work in

combination with Immergas timer thermostats.

e external probe must be electrically connected

as indicated in the Fig. 3-5, 3-6, 3-11, 3-12, 3-13,

3-14 or 3-16.

• Control of the High-Temperature zone. e

correlation between ow temperature to the

system and external temperature is determined

by the parameters set on the boiler. See boiler

instructions manual.

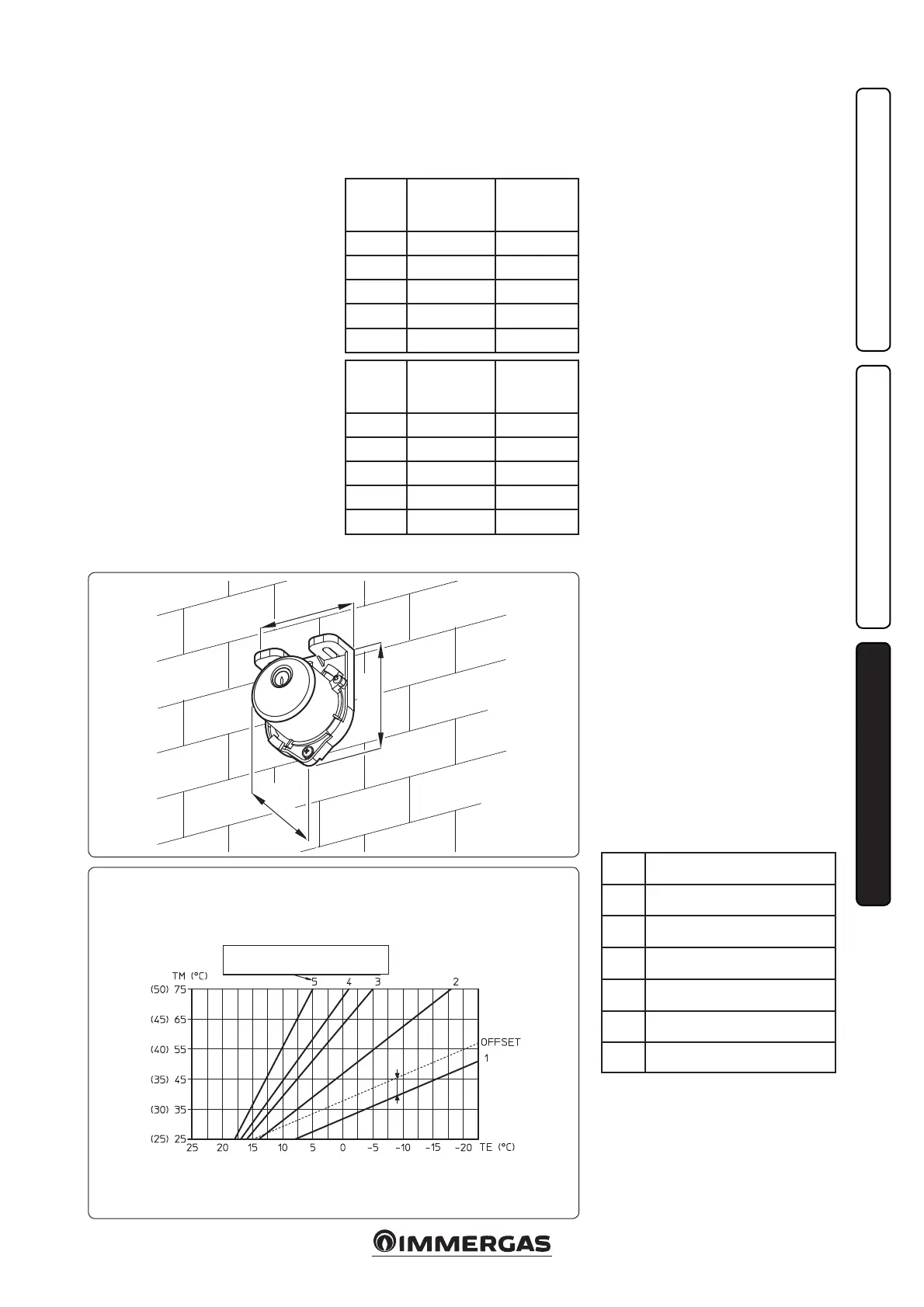

• Control of the Low-Temperature zone. e

correlation between ow temperature to the

system and external temperature is determined

by the position of the trimmer (15 or 16 Fig.

3-18) on the zone board according to the curve

represented in the diagram (Fig. 3-20).

• No external temperature probe. To set the ow

temperature of the low-temperature zones, it

is necessary to act using a screwdriver on the

trimmer (R12 or R13) present on the zone

control unit following the table provided below

(15 or 16 Fig. 3-18).

Low-temperature zone

Correction law of the ow temperature depending on the external temperature and user

adjustments of the central heating temperature.

FT = Low-temperature zone Flow Temperature

ET = External temperature.

Trimmer

position

R12 or R13

Low-temperature

zone ow

(25 ÷ 50 °C)

High-temperature

zone ow

(25 ÷ 75 °C)

1 25 °C 25 °C

2 30°C 37.5 °C

3 35°C 50 °C

4 40°C 62.5 °C

5 50 °C 75°C

Trimmer

position

R12 or R13

Low-temperature

zone ow

(35 ÷ 50 °C)

High-temperature

zone ow

(35 ÷ 75 °C)

1 35°C 35°C

2 39 °C 45°C

3 43 °C 55 °C

4 47 °C 65°C

5 50 °C 75°C

Note: using an IMG BUS connection to the

Superior kW boiler, the low-temperature zones

are regulated on the boiler display.

Note: when the external probe is connected, the

OFFSET action can be regulated (with Superior

kW boilers only).

3.15 TROUBLESHOOTING.

- Presence of air in the system. Check the open-

ing of the boiler vents, the central heating

system and the DIM, act on the 3-way mixing

valve, keeping it open for de-aeration (only for

H-LT and H-2LT version). Make sure the sys-

tem pressure and expansion vessel factory-set

pressure values are within the set limits; the

factory-set value for the expansion vessel must

be 1.0 bar, and system pressure between 1 and

1.2 bar.

- Low-temperature safety thermostat interven-

tion. It can depend on the blocked pump, the

blocked mixing valve or an anomaly on the

P.C.B. Check the correct operation of the com-

ponents indicated above, making sure that the

anomalies signalled by ashing of the LEDS H9

or H10 (according to the cases) on the P.C.B.

disappear.

- Low-temperature ow regulation NTC probe

anomaly. Replace the component and/or check

its correct operation, making sure that the

anomaly signalled via switch-on of the LEDS

H9 or H10 (according to the cases) on the

P.C.B. disappears.

- Low-temperature zone flow temperature

insucient or too low. It can depend on an

incorrect regulation of the trimmer (R12 or

R13) present on the P.C.B. from the blocked

or broken mixing valve (only for H-LT and

H-2LT version), or on the temperature set on

the lower boiler with respect to that requested

in the low-temperature circuit (only for boil-

ers connected without IMG BUS). Check the

correct regulation of the trimmer, check the

correct operation of the mixing valve (only for

H-LT and H-2LT versions). Make the boiler

function with a ow temperature over that set

for the low-temperature zone (only for boilers

connected without IMG BUS).

- e table below identies the errors displayed

on the boiler, when the manifolds are connect-

ed with the IMG BUS:

Code Description

32

Zone 2 Low-Temperature probe

anomaly

33

Zone 3 Low-Temperature probe

anomaly

34

Low-temperature zone 2 safety ther-

mostat intervention

35

Low-temperature zone 3 safety ther-

mostat intervention

36 IMG BUS communication loss

46

DIM safety thermostat intervention

(optional)

POSITION OF THE TRIMMER

ZONE P.C.B.

In brackets, temperature value with 25°/50° range

Loading...

Loading...