25

STEMkW Special ed 01/08 EOLO Mini kW Special

Technical Documentation

Technical Documentation

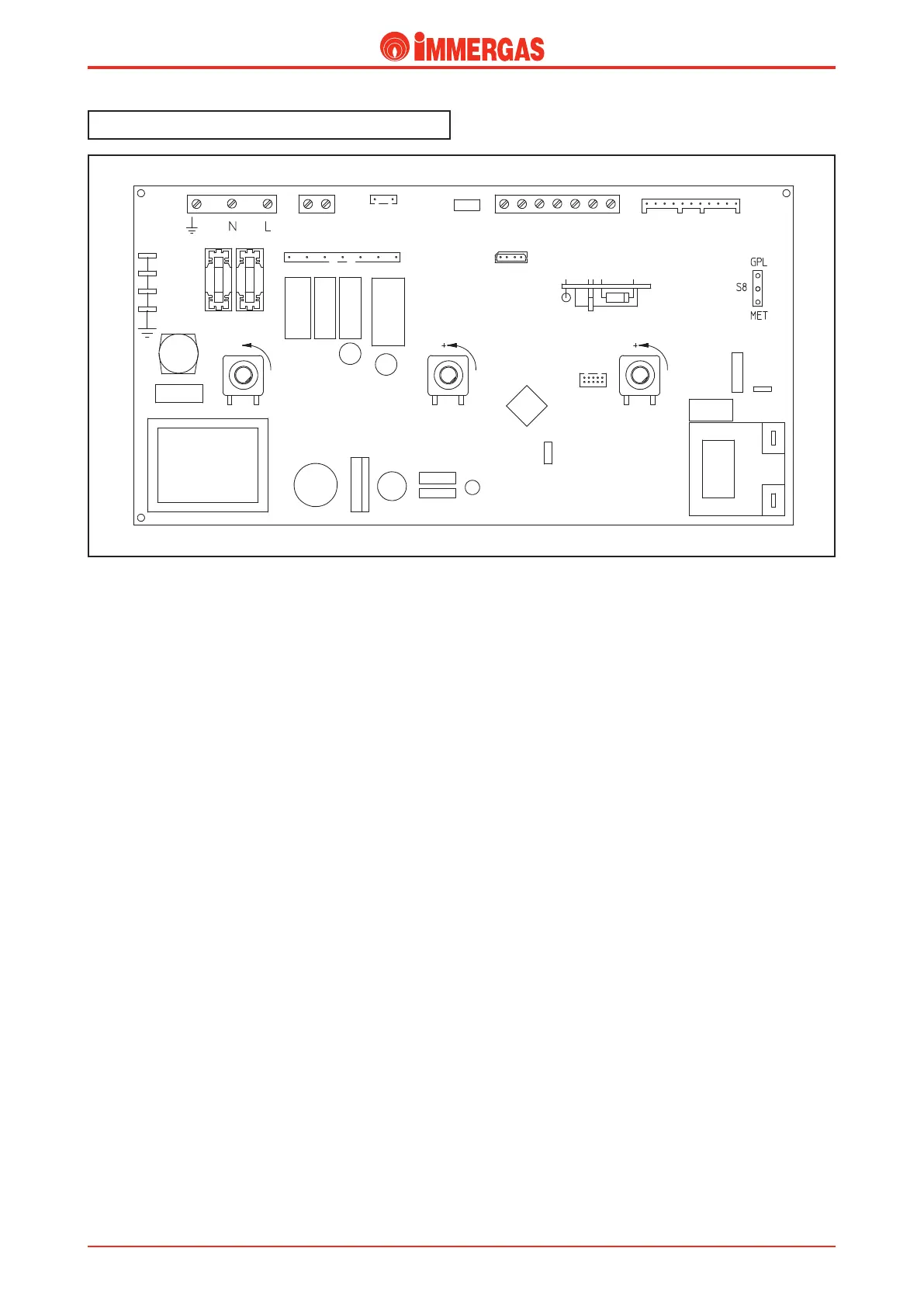

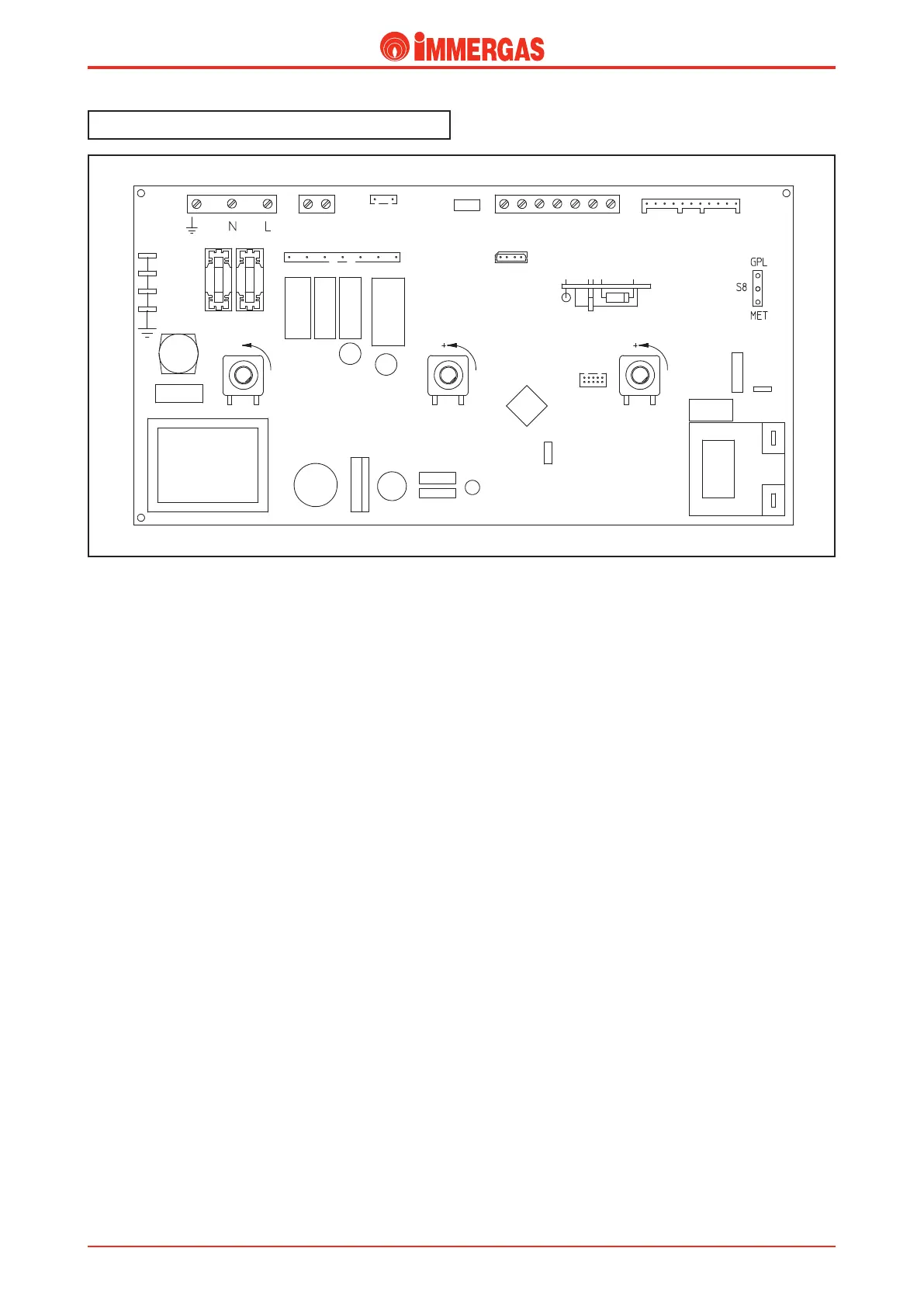

Modulation P.C.B..

Inside the boiler control panel an integrated electronic micro-

processor P.C.B. is located which manages electronic de vices

onP.C.B. of the appliance, it linearly modulates burner power

and thanks to a series of LED’s, shows the status of the applian-

ce, signaling when any safety device was activated.

e same P.C.B. is assembled on every model whether with

conventional ue or sealed chamber (EOLO/NIKE Mini kW

Special); rec ognition of the various types of boiler function is

automatic as it depends on how the boiler is wired.

A single printed circuit P.C.B. is supplied as spare part,

which via the relevant software and the setting of some

parameters, can be installed on EOLO/NIKE Mini kW

Special and AVIO/ZEUS kW boiler models (See printed

circuit board programming procedure).

Integrated P.C.B. is always powered regardless of main switch

(R10) position.

P.C.B. periodically self-tests in order to verify correct operation.

While operating in central heating mode or while the boiler is

in Stand-by, self-test function is enabled every 18 hours after

last test or last time the boiler was powered. In DHW mode,

self-test starts within 10 minutes after last time water was drawn

from the tap (self-test lasts approximately 10 seconds).

Warning: during self-test, the boiler and all signals remain

inactive.

Operation.

Central heating request.

By selecting the “WINTER” function with the main switch

(R10), the boiler is enabled to work in the central heating

mode.

When the contact of the room thermostat closes (S20), the

integrated P.C.B. powers the boiler circulator (M1) by means of

the K2 relay and, by the switching over of the K4 relay contact,

powers the motor (M) of the 3-way valve (M30) which keeps

working until limit switch “1” opens when the central heating

position is reached.

In the meanwhile, if the contact of the ue pressure switch

(S6) is idle “NC”, the adjustment circuit powers the fan (M20)

by means of relay K3.

With the enable of the safety thermostat (E4) and consequent

switching over of the ue pressure switch to “NO” (S6), and

if the temperature measured by the ow probe (B1) is under

that set on the control panel with the central heating tempe-

rature trimmer, the integrated P.C.B. excites the request relay

K1 that causes the 2 contacts to close allowing the ignition

cycle to start.

During the rst few seconds after the gas valve (Y1) has been

powered, the current to the modulating coil (Y2) is limited to

the predened soft ignition current. e burner will then go

to the minimum value set by setting the “Minimum Central

Heating Power*” parameter and then reach the maximum

value set (if required) by setting the “Maximum Central Hea-

ting Power*” parameter in a time set in the “Central Heating

Ramp Time*” parameter.

Subsequently the signal is varied directly proportionate to

the dierence between the temperature set with the central

heating temperature trimmer (R6) and that measured with

the ow probe (B1).

When the set temperature (+5°C) is exceeded, the contact of

the K1 relay opens and the burner switches o. Re-ignition

time depends on how the “Central Heating Ignitions Timer*”

parameter is set.

Each time the burner switches o the fan keeps working for

30 seconds.

'64&4

53"/4'03.&3

."*/4&-&$503

48*5$)

%0.&45*$)05

8"5&3

$&/53"-

)&"5*/(

Loading...

Loading...