IE

24

3

Solar circuit lling.

N.B.: If errors occur during installation, opera-

tion and maintenance, due to non compliance

with the technical laws in force, standards or in-

structions contained in this manual (or however

supplied by the manufacturer), the manufacturer

accepts no contractual and extra-contractual

liability for any damages and the appliance war-

ranty is invalidated.

e system can only be lled when:

- any operational residues have been eliminated

that may cause obstructions and deteriorate

the features of the glycol over time;

- any presence of water in the system has been

eliminated, which could otherwise cause dam-

age to the system in winter;

- the absence of leaks has been verified by

checks using air;

- the storage tank unit has been lled;

- the expansion vessel is preloaded as per the

manufacturer's or qualified professional's

instructions.

e system must be lled only using the glycol

supplied by Immergas via an automatic pump.

e system must be lled with vent valve closed.

Proceed as follows to ll the system:

1 connect the ow pipe of the automatic pump

to the tting of the lling valve (9 Fig. 4)

located under the pump and open the valve.

2 connect the return pipe of the automatic pump

to the tting of the draining valve (8 Fig. 4)

and open the draining valve.

3 The flow-rate regulator screw (11 Fig. 4)

must be orientated horizontally to ensure the

closure of the integrated ball valve. Leave the

thermometer in the reading position (ON).

4 ll the lling pump tank with the amount of

glycol necessary plus a minimum amount to

be le on the bottom of the tank in order to

prevent air circulating inside the circuit.

5 e lling stage must have a minimum dura-

tion of 20 ÷ 25 minutes. is time is required

to completely remove all air from the circuit.

Every now and again open the ow rate regula-

tor adjustment screw in order to eliminate air

from inside (vertical position).

6 Eliminate any air in the solar circuit preferably

using the so-called "pressure shot" method,

which consists in raising the lling pressure

of the circuit followed by a quick opening of

the return valve (8 Fig. 4). is method allows

air to be expelled from the circuit.

7 Close the lling cock and switch the lling

pump o, open the regulator screw of the ow

rate regulator (notch in vertical position).

8 Leave the circuit pressurised. Any pressure

drop indicates a leak in the system.

9 Set the functioning pressure in the circuit at

2 bar + 0.1 bar for every metre in the distance

between the solar collector and the expan-

sion vessel (practically, set the same pressure

between expansion vessel and system).

10 Switch the solar pump on at a maximum speed

and make it run for at least 15 minutes.

11 Disconnect the lling pump and close the

ttings using the relevant screw caps.

Do not ll the system in conditions with strong

insolation and with the manifolds at high

temperatures.

Make sure that all air bubbles have been com-

pletely eliminated.

Solar circuit vent.

Any air present in the system must be bled:

- on start-up (aer lling);

- if necessary, e.g. in the case of breakdown.

Attention: danger of burns from the liquid

contained in the collectors.

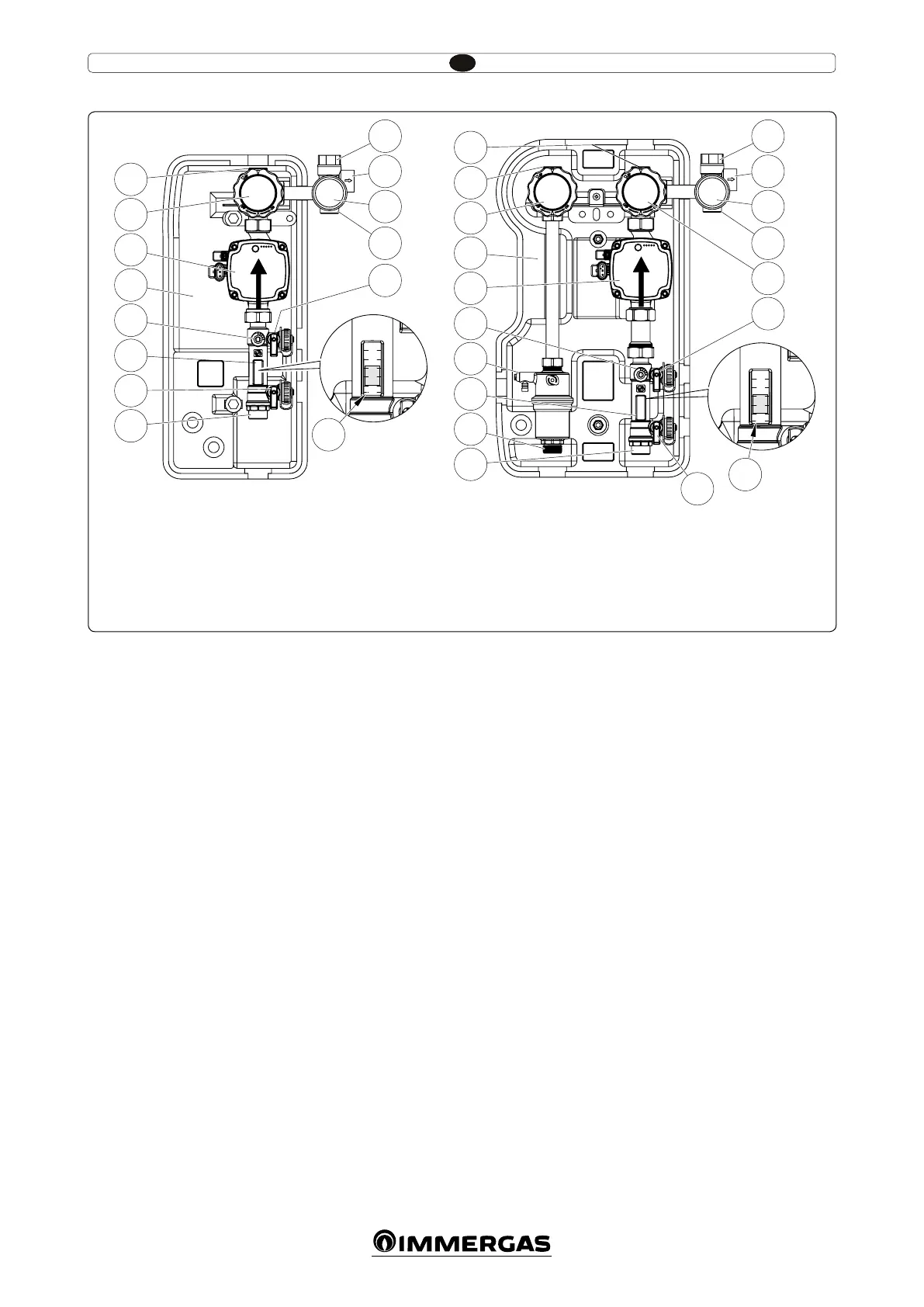

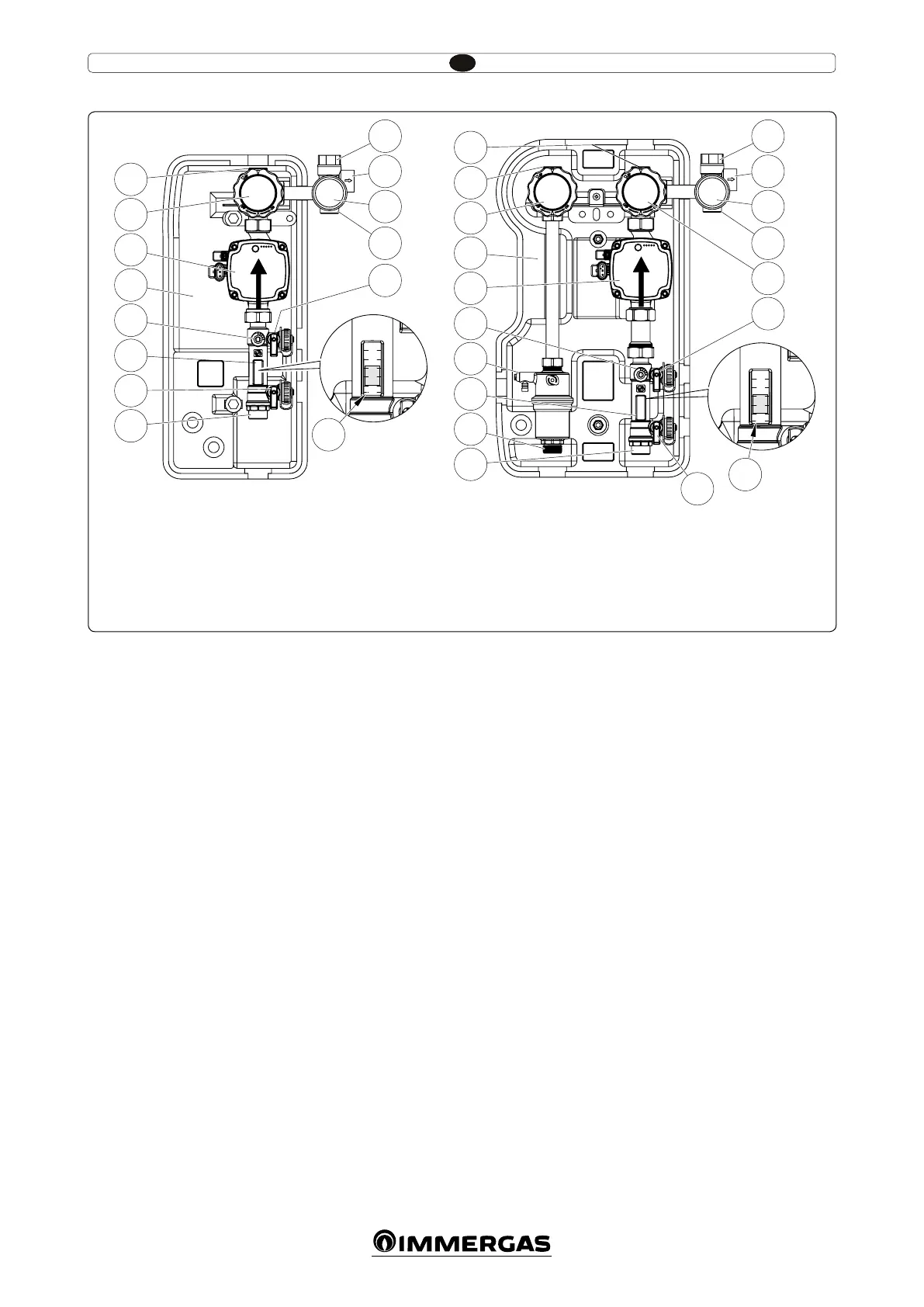

Main components.

Key:

1 - Solar pump

2 - Non-return valve, thermometer and

cock

3 - Valve drain tting

4 - Flow meter

5 - 6 bar safety valve

6 - 3/4” connection for expansion vessel

7 - Manometer

8 - Draining valve

9 - Filling valve

10 - Insulating casing

11 - Flow rate regulator

12 - Boiler inlet

13 - Output towards solar collector

14 - Reference for ow rate reading

15 - Non-return valve, thermometer and

cock

16 - Degasser

17 - Inlet from solar collector

18 - Output towards boiler

1

2

3

4

5

6

7

6

10

11

1

4

8

12

2

13

3

14

9

1

2

3

4

5

6

7

6

3

14

13

17

15

10

1

16

18

2

11

12

4

9

8

Loading...

Loading...