23

INSTALLERUSER

MAINTENANCE TECHNICIAN

3.16 APPLIANCE CHECK AND

MAINTENANCE.

e following checks and maintenance should

be performed every 24 months.

- Clean the ue side of the heat exchanger.

- Clean the main burner.

- If deposits are detected in the combustion

chamber one must remove them and clean the

heat exchanger coils using nylon or sorghum

brushes; it is forbidden to use brushes made of

metal or other materials that may damage the

combustion chamber itself.

- Check the integrity of the insulating panels

inside the combustion chamber and if damaged

replace them.

- Visually check for water leaks or oxidation

from/on fittings and traces of condensate

residues inside the sealed chamber.

- Check contents of the condensate drain trap.

- Via the condensate drain cap check that there

are no residues of material that clog condensate

passage; also check that the entire condensate

drain circuit is clear and ecient.

In the event of obstructions (dirt, sediment,

etc.) with consequent leakage of condensate

in the combustion chamber, one must replace

the insulating panels.

- Check that the burner seal gaskets and the lid

are intact and perfectly ecient, otherwise

replace them. In any case the gaskets must be

replaced at least every two years, regardless of

their state of wear.

- Check that the burner is intact, that it has no

deformations or cuts and that it is properly

xed to the combustion chamber lid; otherwise

it must be replaced.

- Visually check that the water safety drain valve

is not clogged.

- Check that, aer discharging system pressure

and bringing it to zero (read on boiler pressure

gauge), the expansion vessel pressure is at 1.0

bar.

- Check that the system static pressure (with

system cold and aer relling the system by

means of the lling valve) is between 1 and 1.2

bar.

- Visually check that the safety and control

devices have not been tampered with and/or

shorted, in particular:

- temperature safety thermostat;

- Check the condition and integrity of the electri-

cal system and in particular:

- supply voltage cables must be inside the

fairleads;

- there must be no traces of blackening or

burning.

- Check ignition and operation.

- Check correct calibration of the burner in

domestic hot water and central heating phases.

- Check the operation of the appliance control

and adjustment devices and in particular:

- system regulation probes intervention;

- domestic hot water control thermostat inter-

vention.

- Check sealing eciency of the gas circuit and

the internal system.

- Check the intervention of the device against

no gas ionisation ame control. e relative

intervention time must be less than 10 seconds.

N.B.: in addition to maintenance, one must also

check the thermal system, with frequency and

procedures that comply with the indications of

the technical regulations in force.

3.17 COMBUSTION PARAMETERS.

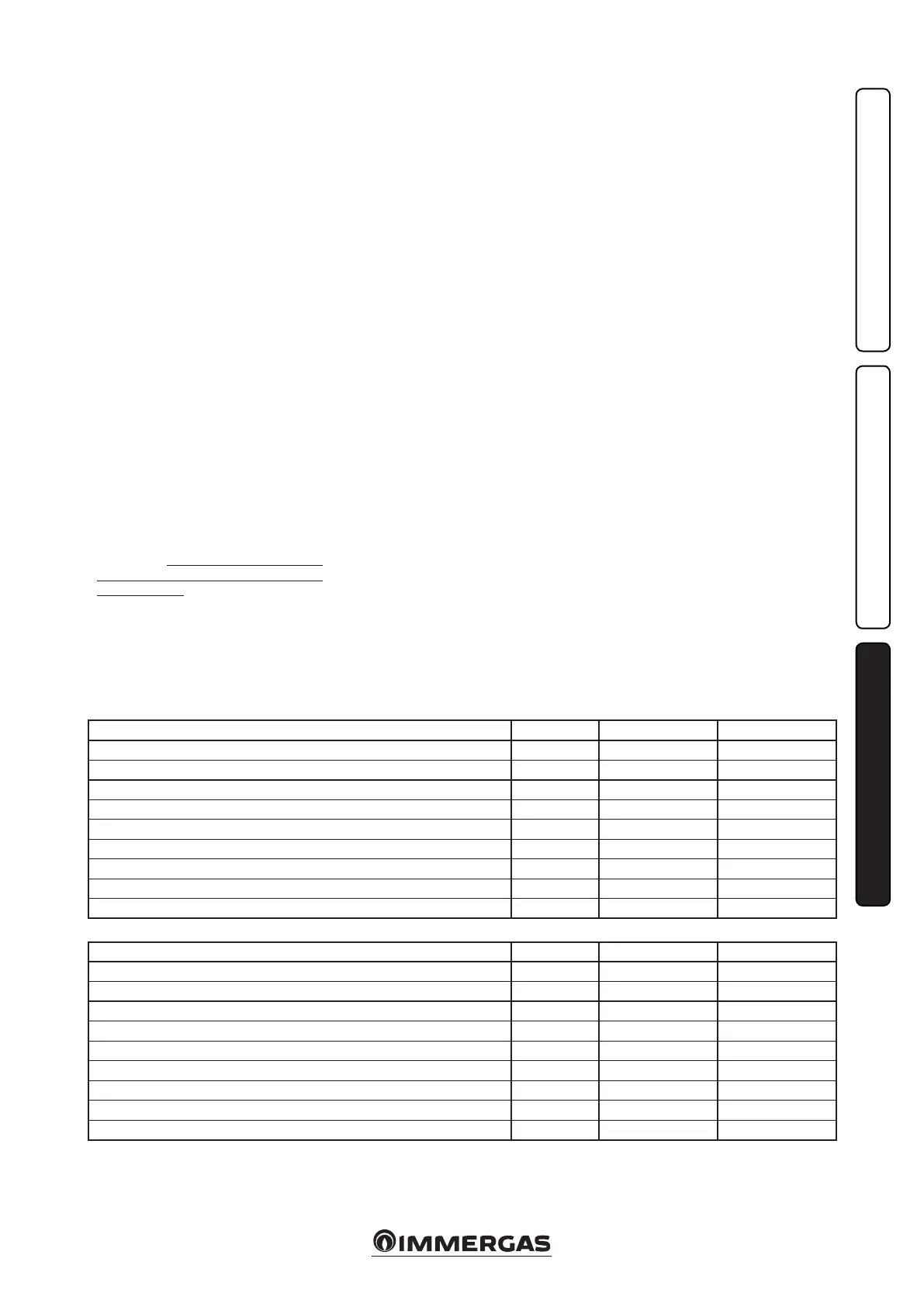

INTEC 12 SYSTEM EXTERNAL NG (G20) Universal LPG (G31)

Gas nozzle diameter mm 3,80 2,80

Supply pressure kPa 1,13 2,75

Flue ow rate at nominal heat output kg/h 19 19

Flue ow rate at min heat output kg/h 4 4

CO

2

at Nom Q./Min. % 9,60 / 8,90 11,00 / 10,30

CO with 0% O

2

at Nom Q /Min. - 0,00125 / 0,00003 0,00173 / 0,00003

NO

X

with 0% O

2

at Nom Q /Min. mg/kWh 30 / 13 35 / 17

Flue temperature at nominal output °C 63 64

Flue temperature at minimum output °C 60 62

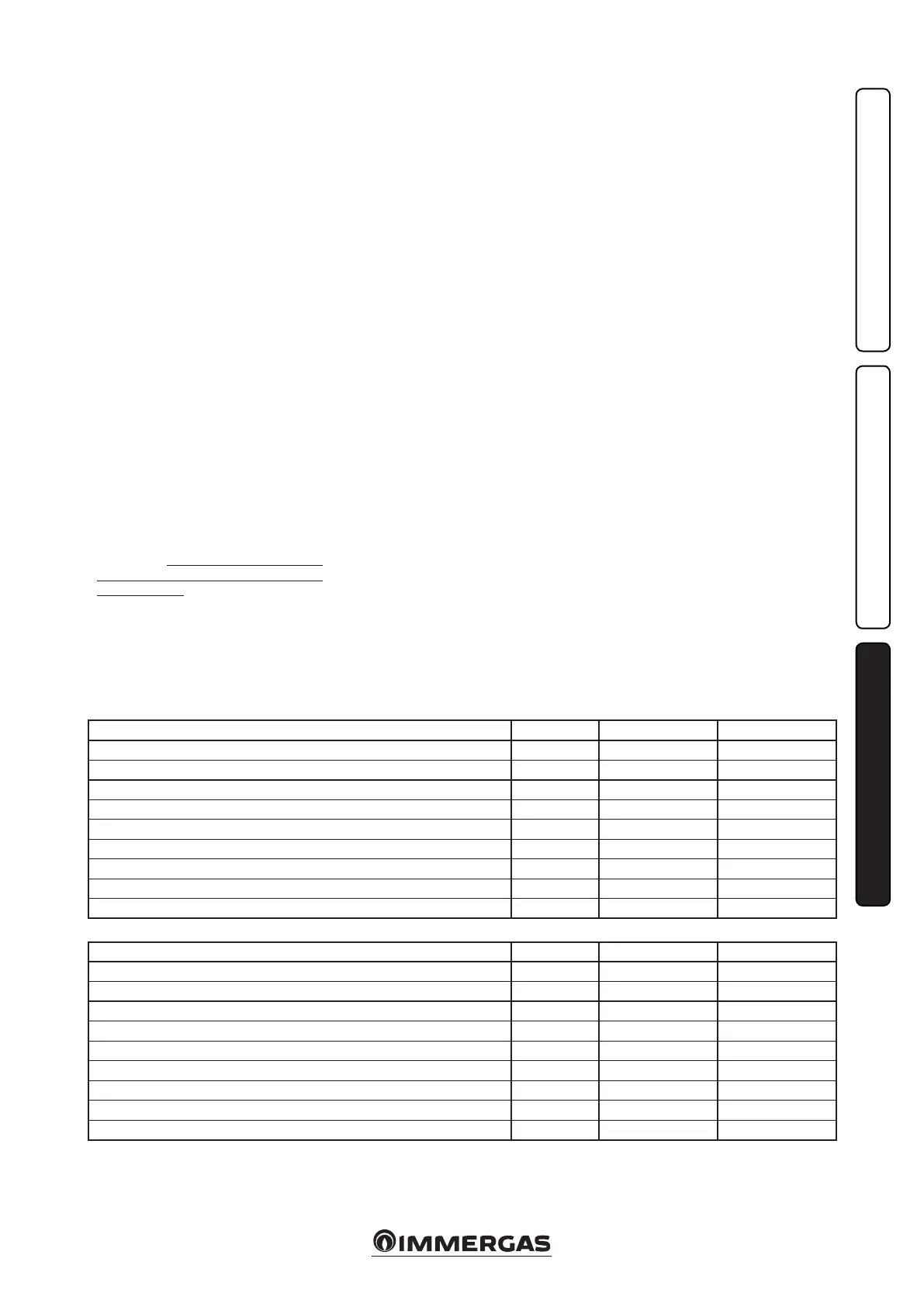

INTEC 30 SYSTEM EXTERNAL NG (G20) Universal LPG (G31)

Gas nozzle diameter mm 6,90 4,80

Supply pressure kPa 1,13 2,75

Flue ow rate at nominal heat output kg/h 48 49

Flue ow rate at min heat output kg/h 10 10

CO

2

at Nom Q./Min. % 9,45 / 8,90 10,60 / 9,70

CO with 0% O

2

at Nom Q /Min. - 0,00153 / 0,00001 0,00160 / 0,00003

NO

X

with 0% O

2

at Nom Q /Min. mg/kWh 51 / 17 61 / 25

Flue temperature at nominal output °C 40 40

Flue temperature at minimum output °C 64 63

Loading...

Loading...