6

45

31

58

1-4

1-7

1-8

1-5 1-6

INSTALLERUSER

MAINTENANCE TECHNICIAN

POWER SUPPLY CABLE

Condensate drain. To drain the condensate

produced by the appliance, it is necessary to

connect to the sewer system by means of acid

condensate resistant pipes i.e. p.v.c. having an

internal diameter of at least 13 mm. e system

connecting the appliance to the drainage system

must be carried out in such a way as to prevent

freezing of the liquid contained. Connections

must comply with national and local regulations

on discharging to waste waters, condensate must

not discharge to storm water. Pipes must be on

gradient to drain.

N.B.: ll the trap with water before operating

the boiler.

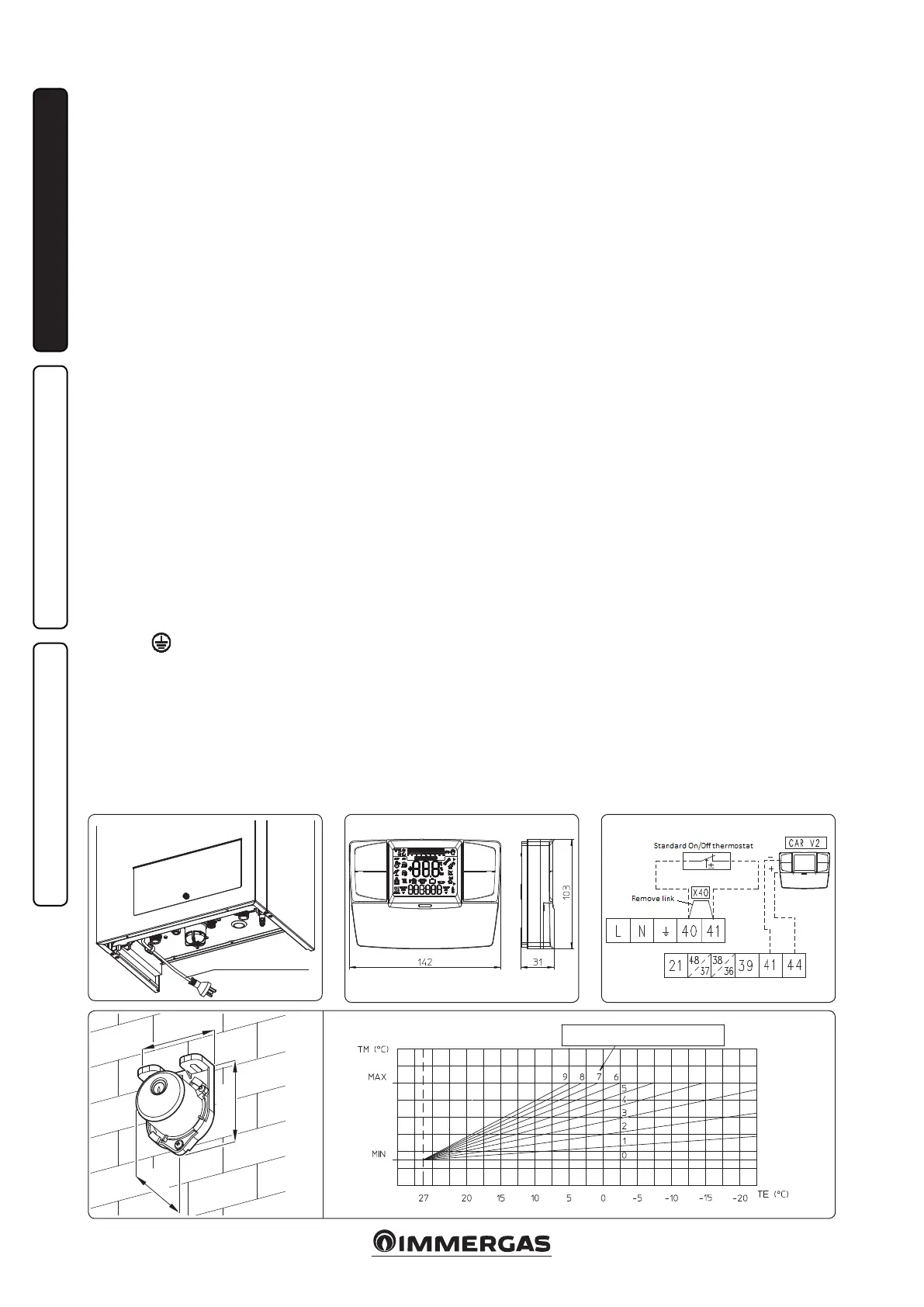

Electrical connection: The “INTEC 12-30

SYSTEM EXTERNAL” boiler has an IPX5D

protection rating for the entire appliance.

Electrical safety of the appliance is reached only

when it is correctly connected to an ecient

earthing system as specied by current safety

standards.

Attention: Immergas/Hunt Heating declines

any responsibility for damage or physical injury

caused by failure to connect the boiler to an

ecient earth system or failure to comply with

the reference standards.

Also ensure that the electrical installation

corresponds to maximum absorbed power

specifications as shown on the boiler data-

plate. The boilers come complete with a 1.5

metre power cable that includes an Australian

electrowelded plug. The plug is of type I,

compliant with standard AS 3112. e power

cable must be connected to a 240V ±10% / 50Hz

mains respecting L-N polarity and the earth

connection

. When replacing the power

supply cable, contact a qualied technician (e.g.

Hunt Heating Service Dept) (Fig. 1-4).

In the event of mains fuses replacement on the

connection board, use 3.15A fast fuses. For the

main power supply to the appliance, never use

adapters, multiple sockets or extension leads.

Note: If the condensate cannot be on a gradient

and terminate to drain, then a suitable condensate

neutraliser must be used (available for purchase

from Hunt Heating).

1.5

REMOTE CONTROL CAR

V2

OPTIONAL.

e boiler is prepared for the application remote

control CAR

V2

, which is available as optional kit.

(Fig. 1-5).

Immergas remote control CAR

V2

is connected

with 2 wires only. Carefully read the user and

assembly instructions contained in the acces-

sory kit.

• In addition to the functions described in the

previous point, the CAR panel

V2

enables the

user to control all the important information

regarding operation of the appliance and the

heating system with the opportunity of easily

intervening on the previously set parameters

without having to go to the place where

the appliance is installed. e CAR

V2

panel

is equipped with self-diagnosis to display

any boiler functioning abnormalities. The

climate chrono-thermostat incorporated into

the remote panel enables the system flow

temperature to be adjusted to the actual needs

of the room being heated, in order to obtain

the desired room temperature with extreme

precision and therefore with evident saving in

running costs. e chrono-thermostat is fed

directly by the boiler by means of the same 2

wires used for the transmission of data between

boiler and chrono-thermostat.

CAR

V2

(Optional). e operations described

below must be performed aer having removed

the voltage from the appliance. Any CAR

V2

must

be connected by means of terminals IN+ and

IN- (on the CAR

V2

terminal plate), respecting

polarity at boiler PCB, where IN+ connects to

terminal 44 and IN- connects to terminal 41

(See Fig. 1-6).

Attention: if the Comando Amico Remoto

V2

(CAR

V2

) remote control is used, arrange two

separate lines in compliance with current

regulations regarding electrical systems. No

boiler pipes must ever be used to earth the

electric system or telephone lines.

Ensure elimination of this risk before making

the boiler electrical connections (ALL

ELECTRICAL CONNECTION MUST MEET

ALL LOCAL REGULATIONS).

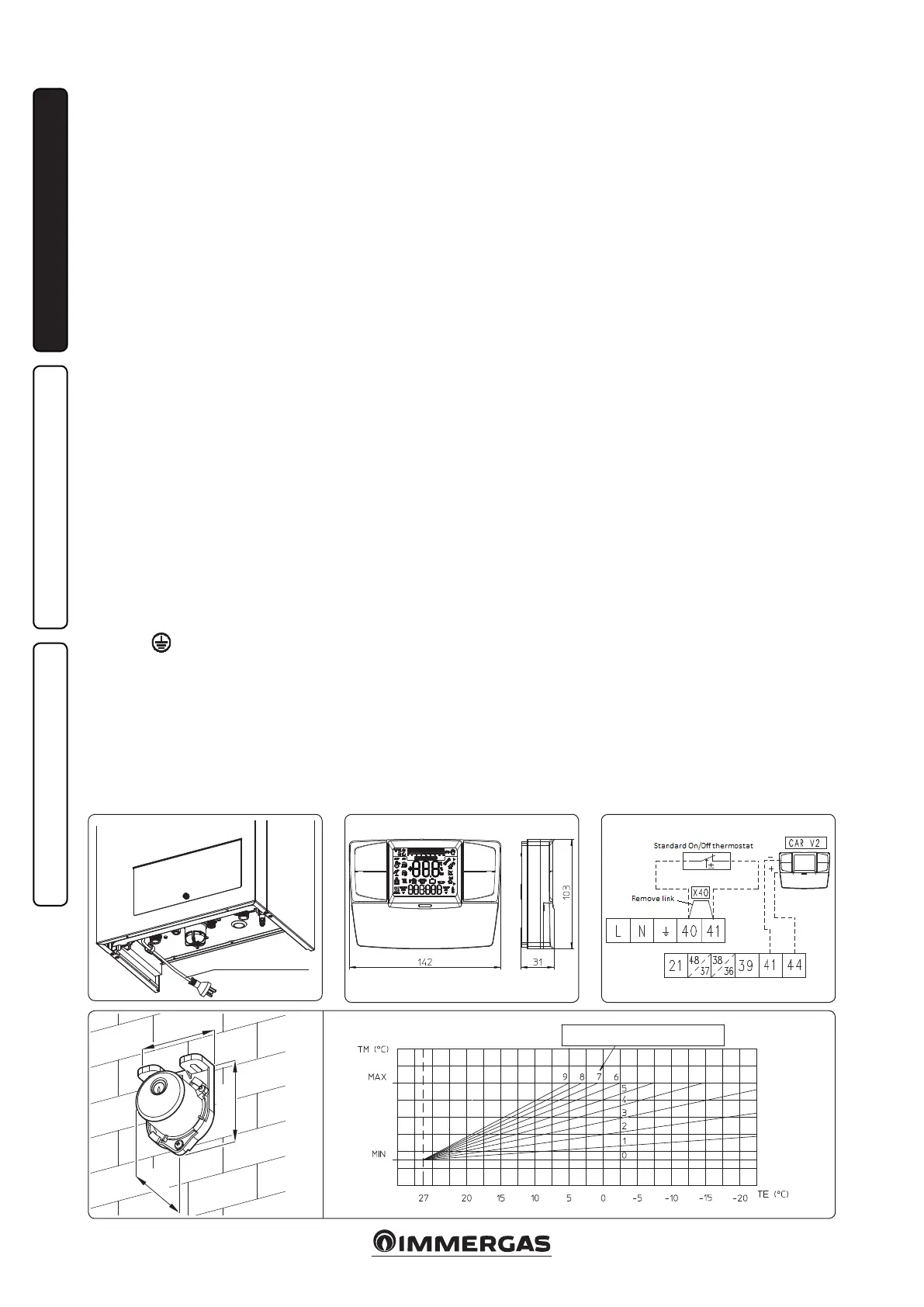

1.6 EXTERNAL PROBE OPTIONAL.

e boiler is prepared for the application of the

external probe (Fig. 1-7), which is available as an

optional kit. Refer to the relative instruction sheet

for positioning of the external probe.

The probe can be connected directly to the

boiler electrical system and allows the max.

system ow temperature to be automatically

decreased when the external temperature

increases, in order to adjust the heat supplied to

the system according to the change in external

temperature. e external probe always operates

when connected, regardless of the presence or

type of room chrono-thermostat used and can

work in combination with Immergas chrono-

thermostats. e correlation between system

flow temperature and external temperature

is determined by the position of the selector

switch on the boiler control panel according to

the curves shown in the diagram (Fig. 1-8). e

electric connection of the external probe must be

made on clamps 38 and 39 on the boiler P.C.B.

(Fig. 3-2).

NB: Thermostat connections if using own

after market thermostat, after removing

manufacturers link, connect to terminals 40

and 41 (Fig. 3-2).

Position of the central heating temperature

user adjustment

Loading...

Loading...