17

STMiN3E ed 09/11 MINI NIKE 3 E

Technical Documentation

Technical Documentation

1

1

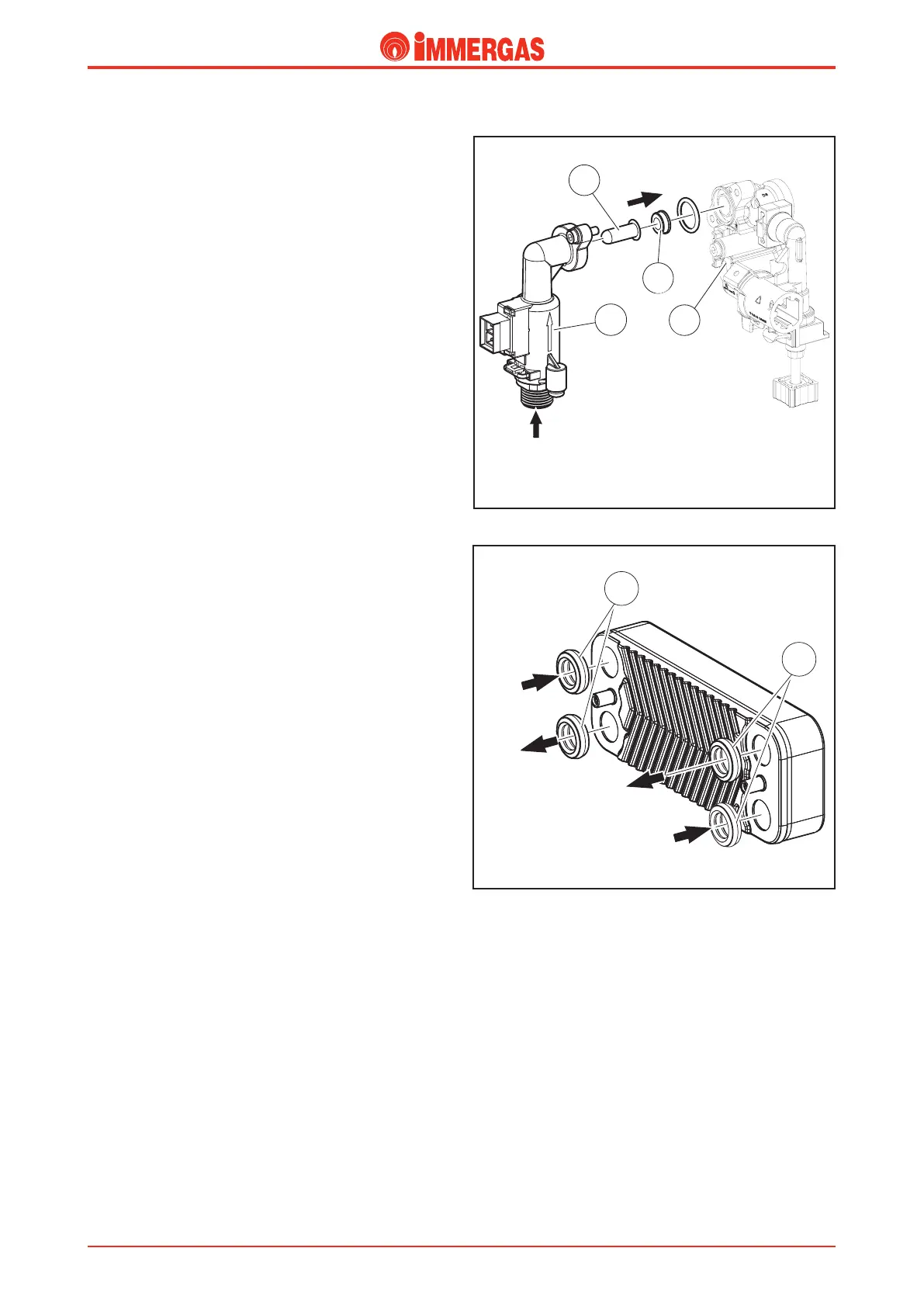

DHW ow switch (2)

With respect to drawing DHW with a ow rate of at least 1.5

l/min and a dynamic pressure of 0.3 bar, the ow switch (1)

enables the boiler functioning in DHW mode.

is takes place by means of a magnet which, lifting when

it is hit by the ow of domestic cold water, approaches an

electric contact (reed relay) and causes shifting due to the

magnetic eect.

e closure of the contact, which is positioned outside the

pipe where the water passes, allows the integrated modulation

P.C.B. to start the DHW priority function mode.

It is made up from two parts (one in brass and one in plastic)

that are coupled and locked with a pin.

A lter (2) is lodged inside of it.

It is attached with two screws to the body of the DHW inlet

(4), which, in turn, the system lling group is connected to.

A 7.1 l/min ow limiter is inserted at the outlet of the ow

switch (3) (at 2 bar).

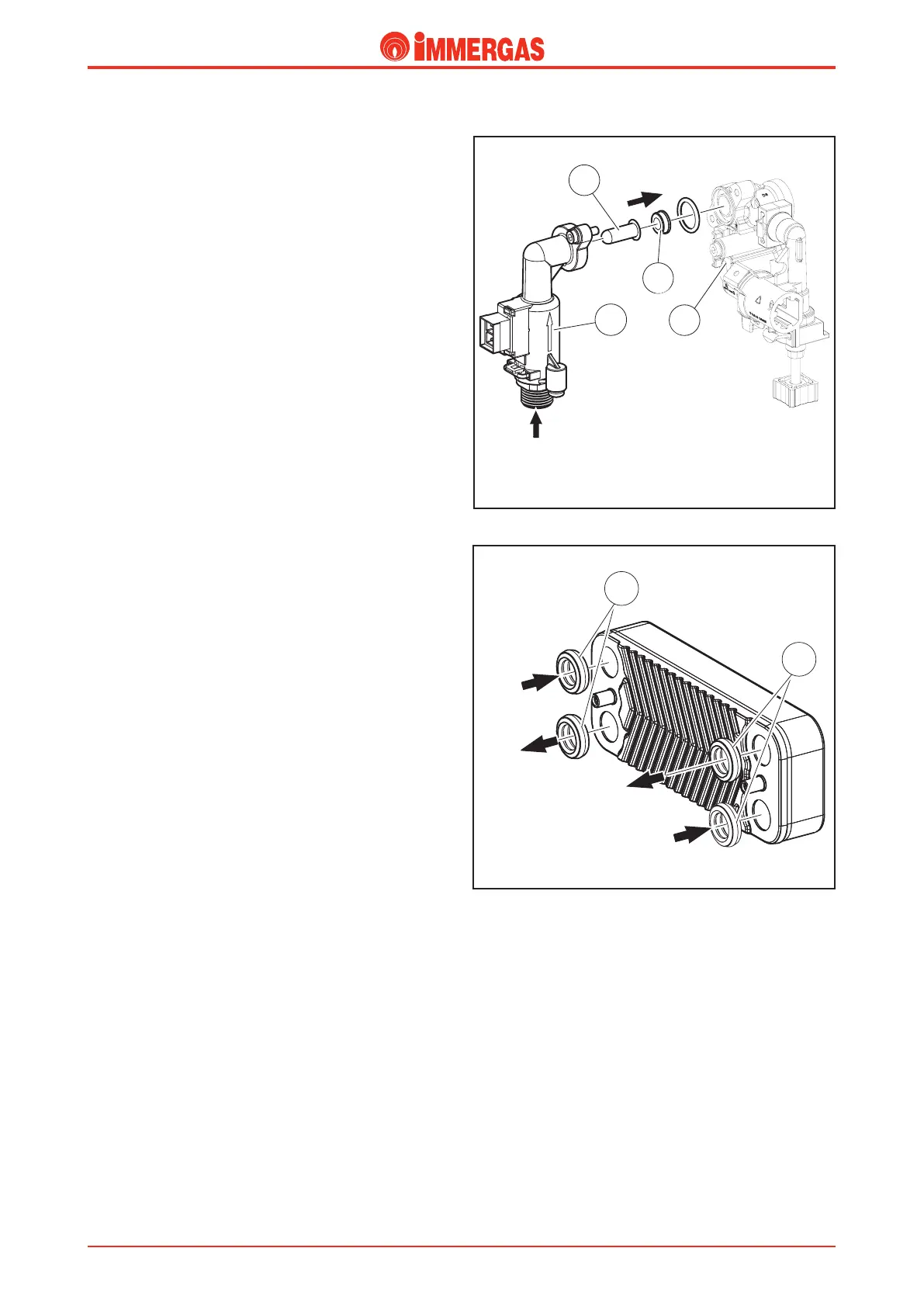

DHW heat exchanger

is is a water-water heat exchanger composed of 12 stainless

steel plates laid one on top of the other, where the water from

the boiler circuit and domestic cold water ows over their

surfaces, against the ow, and where the heat exchange occurs

between the two liquids.

e hydraulic coupling is obtained by using four gasket seals

(1) that allow it to be connected directly to the domestic water

inlet body and domestic water outlet body.

Domestic cold

water inlet

Flow

circuit

primary

Return

circuit

primary

Output

water

hot

domestic

water

Inlet

water

cold

domestic

water

1

2

3

4

Loading...

Loading...