18

STMiN3E ed 09/11 MINI NIKE 3 E

Technical DocumentationTechnical Documentation

e circuit is composed of an atmospheric burner and a

modulating gas valve, which respectively allow the combustion

of the gas and the adjustment of its ow rate.

How it operates

e electric power supply of the main coils (3) causes the

opening of both internal shutters of the valve, thus allowing

the passage of gas towards the burner. e outlet ow/rate

pressure is then adjusted by acting on the gas valve stabiliser

by means of the modulation coil (1).

e fuel is injected , by means of the burner nozzles (6), into

the horizontal Venturi pipes (ramps). Here, an optimal air-gas

mixture is obtained that is ignited by the spark of the ignition

electrode (4).

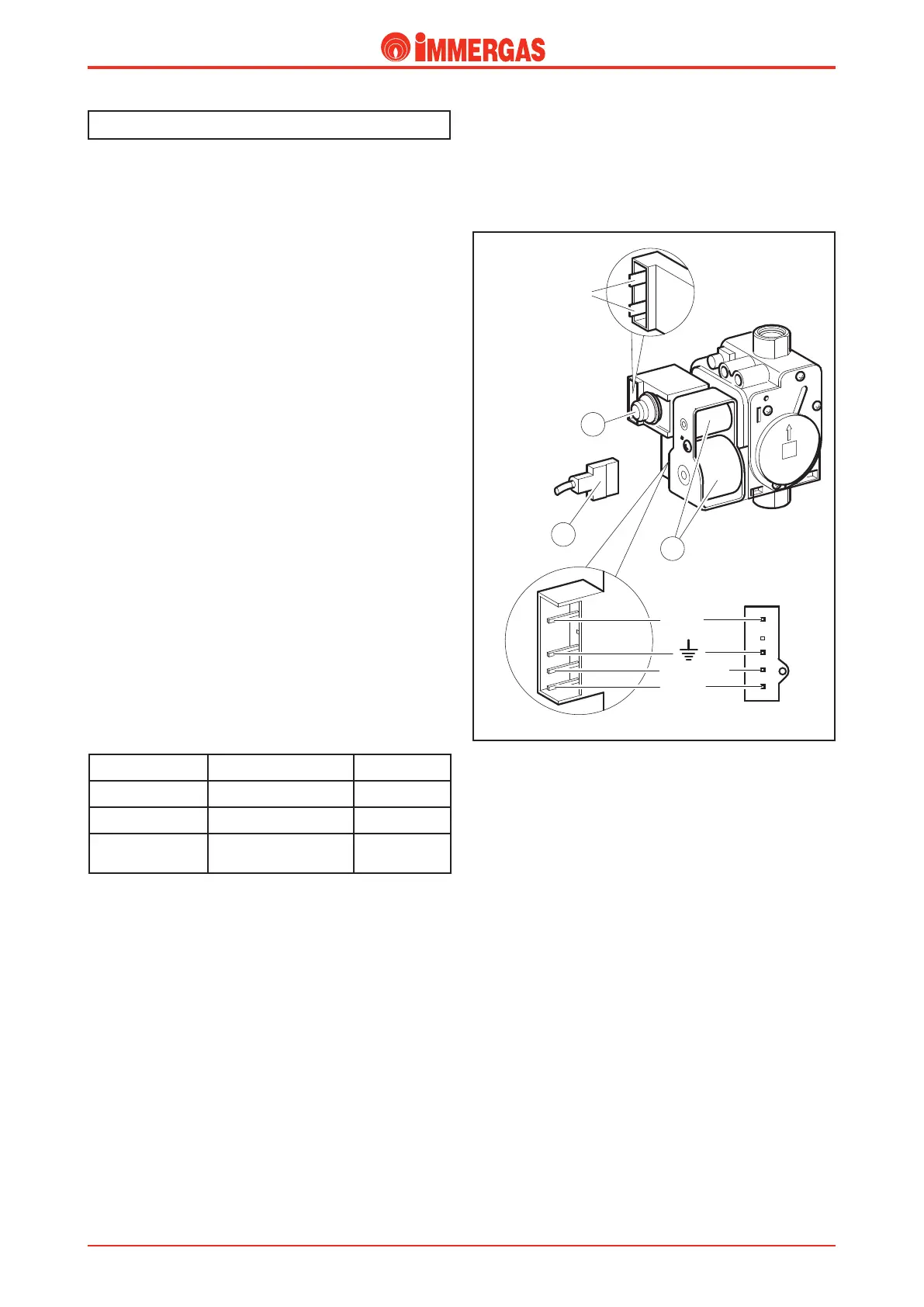

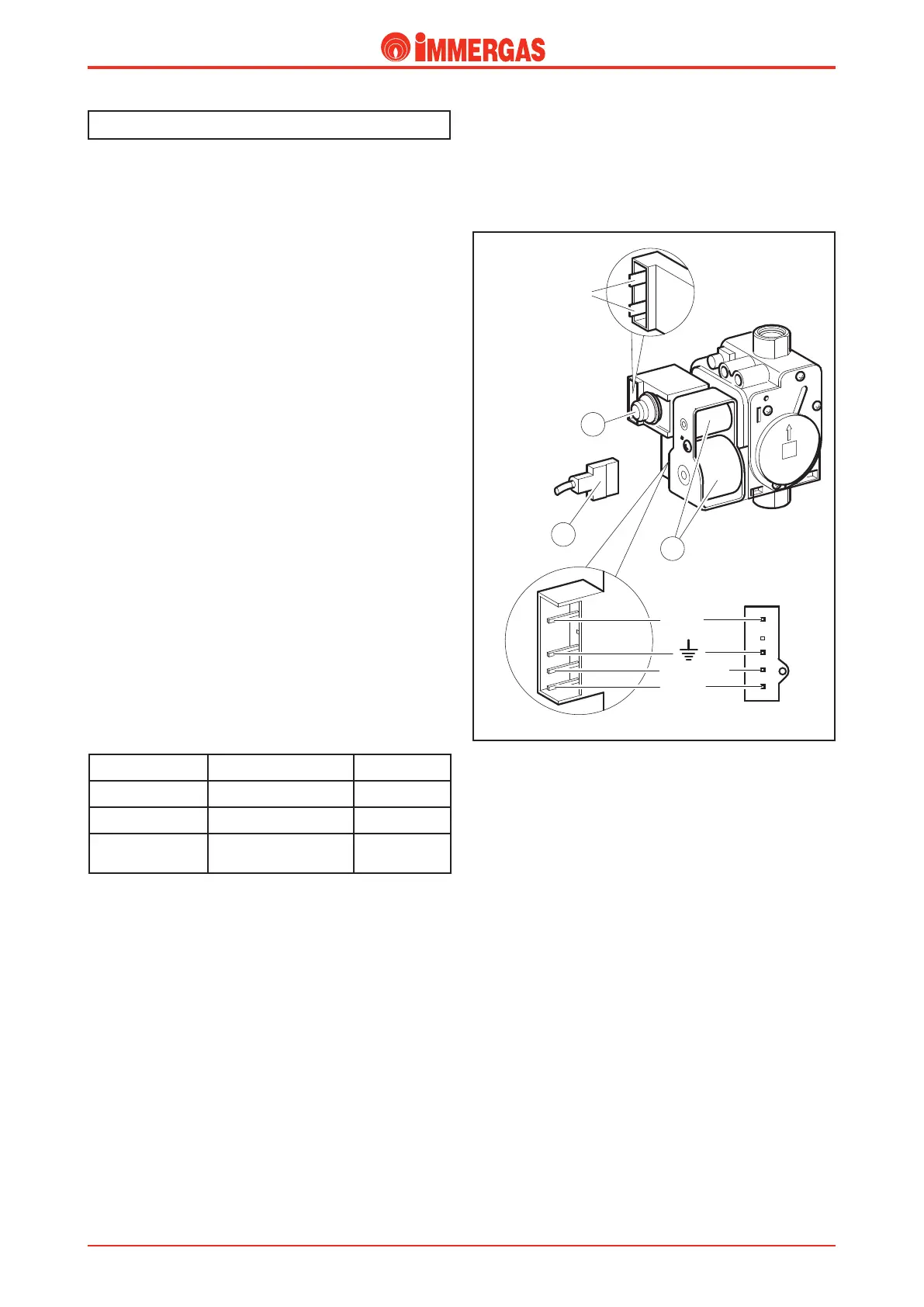

Modulating gas valve (SIT 845)

e gas valve is equipped with two main coils (3) and a

modulation coil (1) controlled by the integrated P.C.B.

The maximum and minimum outlet pressure values are

calibrated on the valve (see gas adjustments).

Main electric coils (3)

ey are two ON-OFF coils that are powered (230 V AC) by

the integrated P.C.B. when burner ignition is necessary.

ey are connected electrically in parallel and powered by the

mains voltage through a specic connector (2).

Modulation coil (1)

It is a low voltage coil that is controlled by the integrated P.C.B.

It acts on the gas valve stabiliser and allows the variation of

the outlet pressure proportionally to the direct current that

passes through it.

Gas circuit

COIL POWER SUPPLY RESISTANCE

EV1 230 V AC 6.25 kΩ

EV2 230 V AC 860 Ω

Modulation coil

250mA DC (G20)

320mA DC (L.P.G.)

22 Ω

Standard values for the boiler at maximum capacity

1

3

2

Modulation

coil

Connector

viewed from the

gas valve

EV1

EV2

Common

Loading...

Loading...