20

STVP ed 02/06 VICTRIX Plus

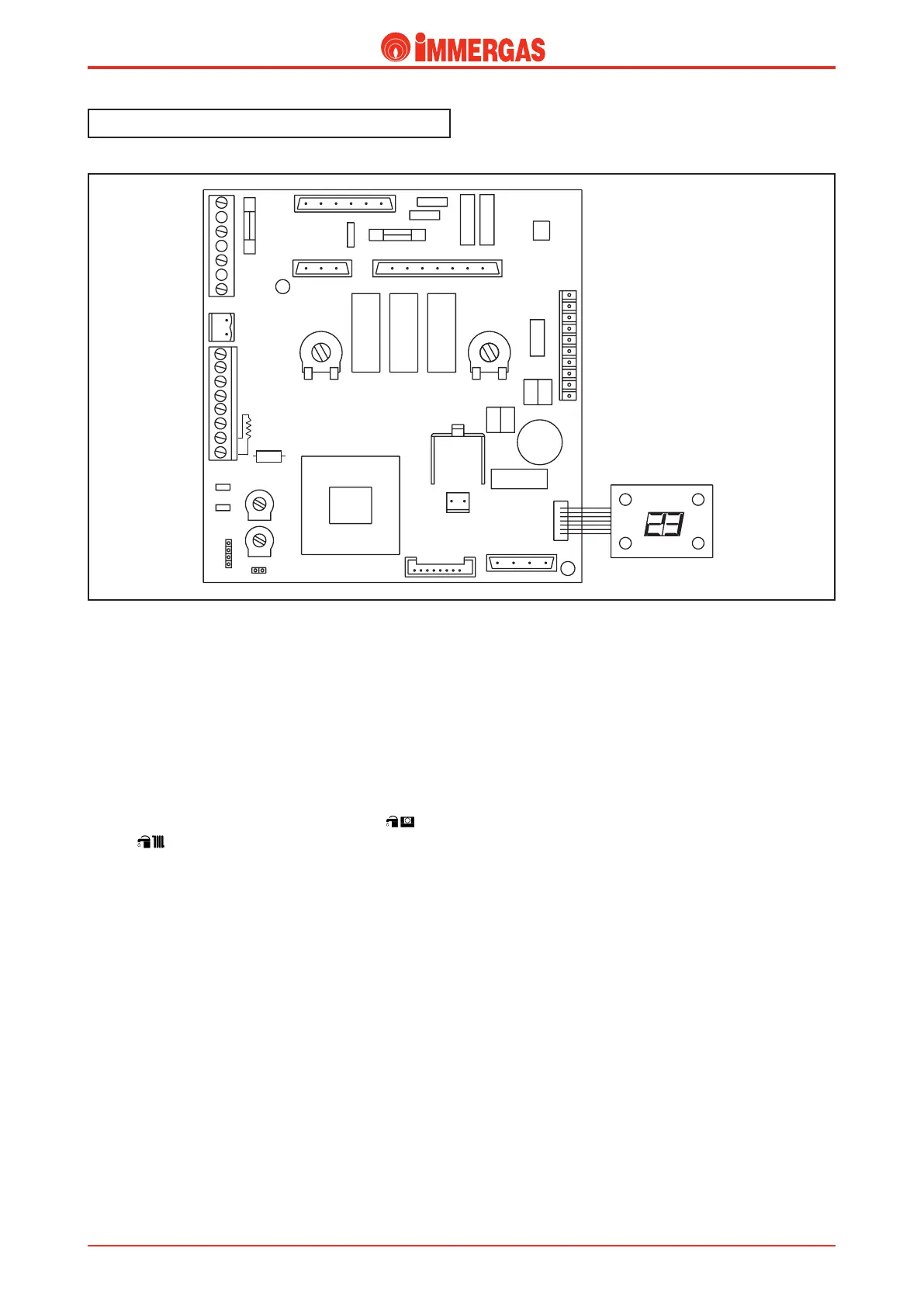

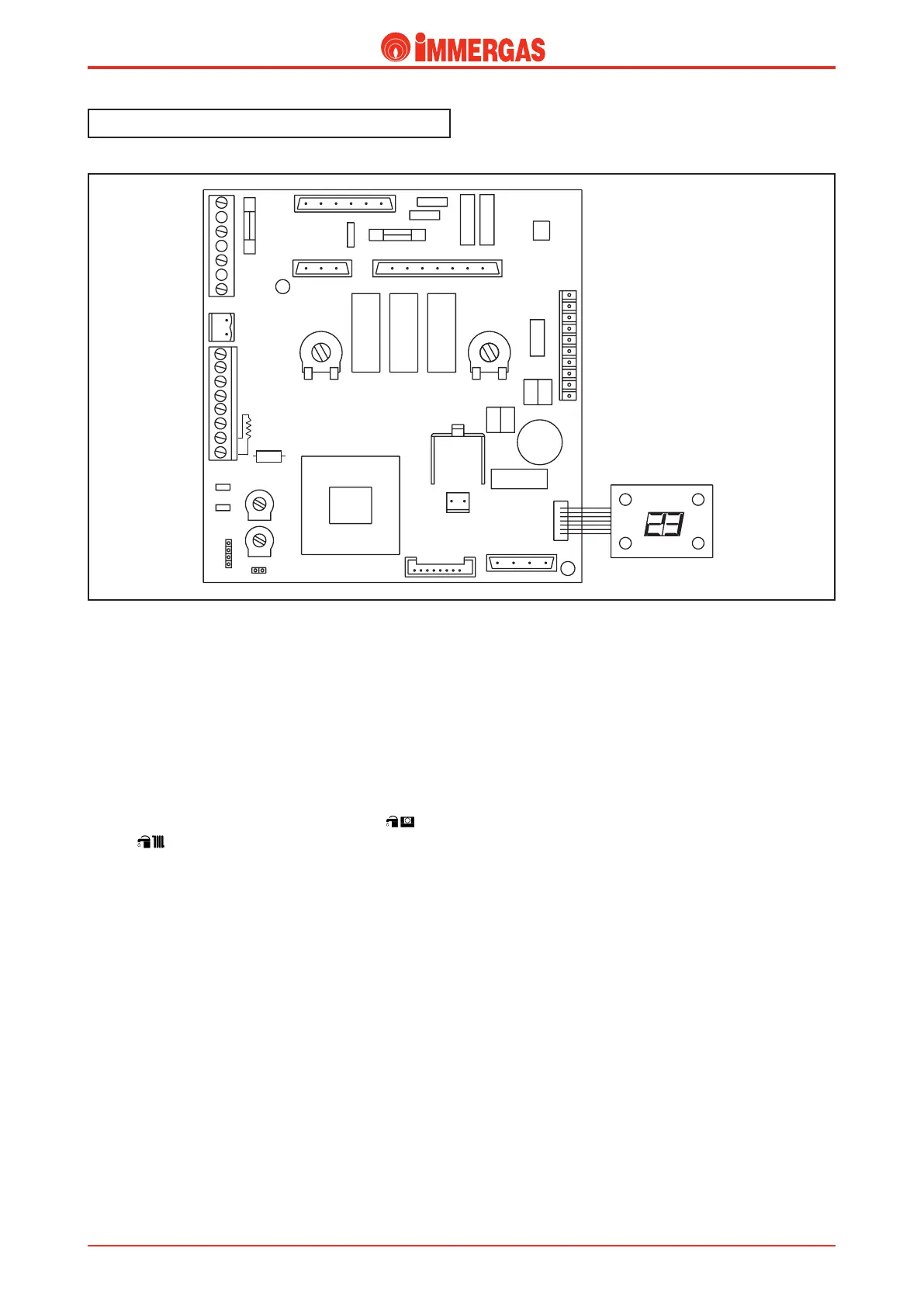

Modulating Control Board.

e boiler features a microprocessor-controlled electronic

board used both on models with the electric 3-way diverter

valve (VICTRIX Plus, VICTRIX Zeus) and on models with the

hydraulic 3-way diverter valve (VICTRIX).

To have the appropriate operating type, act on jumper R6

(jumper present = electric 3-way diverter valve, jumper

absent = hydraulic 3-way diverter valve).

e board is connected to a socket (DISPLAY BOARD)

which, by means of LEDs and a display, shows the boiler

operating status.

e board is powered by the main switch (S1) on (sum-

mer) or (winter).

Operation.

Heating request with a room thermostat.

With the main switch (S1) on WINTER and the room

thermostat contact (TA) closed, the low voltage circuit starts

the circulator (M1) by means of relay K2 and powering the

3-way diverter valve (M3) motor (M) by means of the relay

K1 contact.

e flow of water intercepts the pump pressure switch (S2)

whose contact, on closing, energises the coil of relay K3.

If the temperature read by the heating NTC sensor (B1) is

lower than that set with the heating potentiometer (HEAT),

the fan (M2) starts.

On reaching a speed of 700 rpm (minimum speed for ignition

validation) the board closes the contact of the request relay

(K3).

is results in power reaching the control unit (IGN. BOARD)

and the start of the ignition cycle.

During the ignition phase, the fan works at a speed equal to

half the top speed set with the fan speed adjustment trimmer

(FAN POT.).

Once the flame has been detected (signal from the control unit),

speed is changed (modulated) in a way directly proportionate

to the difference between the temperature set with the heating

potentiometer (HEAT) and that read with the heating NTC

sensor (B1) and, if necessary, reaches the maximum set value

in 50 seconds (maximum heating output).

Once the set value is exceeded, the contact of relay K3 opens

and the burner switches off. To restart the burner you have to

wait at least 180 seconds.

Heating request with the Amico Remote Con-

trol.

If the conditions found by the Amico Remote Control (CAR)

require operation in the heating phase (SUM/WIN selector

switch on WINTER, time programmer request, room temperature

setting above that found), the low voltage circuit starts the circu-

lator (M1) by means of relay K2 and powers the 3-way diverter

valve (M3) motor (M) by way of the K1 relay contact.

e flow of water intercepts the pump pressure switch (S2)

whose contact, on closing, energises the coil of relay K3.

If the temperature read by the heating NTC sensor (B1) is

below that set with the Amico Remote Control (CAR) heating

potentiometer, the fan (M2) starts.

Once a speed of 700 rpm is reached (minimum speed for igni-

tion validation) the board closes the contact of the request

relay (K3).

R1

FAN

SPEED

POT

.

C.H.

POT

.

CM1

PUMP

SWITC

CM2

C.H.

TEMP.

SWITC

H

DL1 DL2

DL3

PU1

Technical DocumentationTechnical Documentation

Loading...

Loading...