10

• The electric supply must not be interrupted or zeroed for more than 3 ms at any time. Between two interruptions it

must not take more than 1 s.

• The interruptions must not overcome 20 % of the tension peak for more than one cycle. Between two interruptions it

must not take more than 1 s.

The manufacturer assumes no liability for any damages to people, things and animals caused by the non-compliance of

the above instructions

Chapter 5 IN FUNCTION - USE

DANGER

WARNING

Before setting the machine in motion it is essential that the Operator and Safety

Ma

nager have read the Instructions Manual and understood all parts of the

machine and activities linked to it (Risks, Dangers, Functionality, Operation,

Protections, Commands, etc.)

5.01

MACHINE CALIBRATION – METERS - INDICATORS

The machine is checked in the factory, using sample equipment periodically checked by officially recognised institutes.

These checks cannot guarantee that the machine, meters and indicators will provide accurate values and results

conforming to the standards in force in the countries the machine has been installed and used in.

Normally such norms envisage calibration check after every movement. In order to obtain correct values and results it

is therefore VITAL that the operator, once the machine has been installed and set up and before official tests, has an

officially recognised body check the machine characteristics, its calibration and results/values reliability. The

manufacturer is exempt from all responsibility in the case of direct and indirect damage from use of the machine without

officially approval by the relevant bodies.

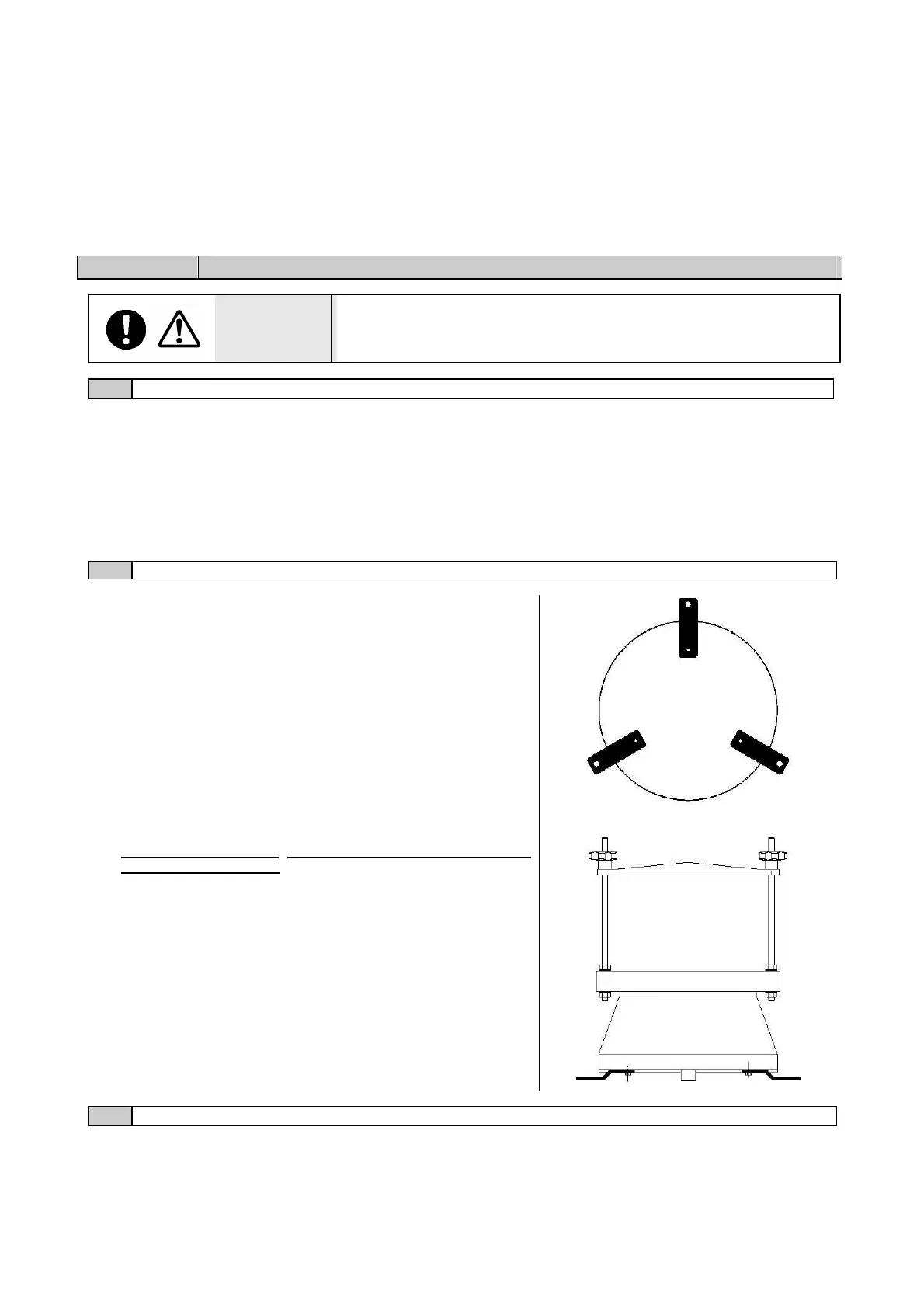

5.02 PLACEMENT ( ONLY SV007 & SV008 MODELS)

For these sieves is important the placement

The vibrant maximum power can reach values such as to

require fixing to the floor of the magnetic shaker.

If the shaker is used more frequently at low intensity values of

vibrant, it is not necessary to fix the shaker to the floor, but if the

shaker is used at its most vibrant intensity should be fixed to the

floor.

The shaker has 3 brackets with holes for fixing to floor, to fix

the shaker, follow these instructions:

Unscrew the three screws and three washers on the

bottom of the shaker.

Interpose the 3 brackets between the bottom of

setaccitatore and the screw heads (see diagram

opposite),and tighten screws.

Use the outer holes

of the brackets to anchor the

shaker to the ground.

N.B.: To anchor the brackets to the floor you must check

carefully the floor:

A. If the floor is very compact and resistant (concrete or

similar) is sufficient use of expansion bolts with a

penetration depth of 70mm

B. If the floor has a consistency less than concrete or if is

composed by friable materials you must use fixing bolts

In these cases it is necessary to use fixing bolts

anchored to the floor by foundations cemented to the

floor.

5.03

EQUIPPING

We give here the right procedures in order which allow to an inexperienced operator tooling up the sieve

shaker properly:

INSTALLATION OF THE THREADED RODS

Loading...

Loading...