6

Chapter 2 TECHNICAL CHARACTERISTICS

2.01

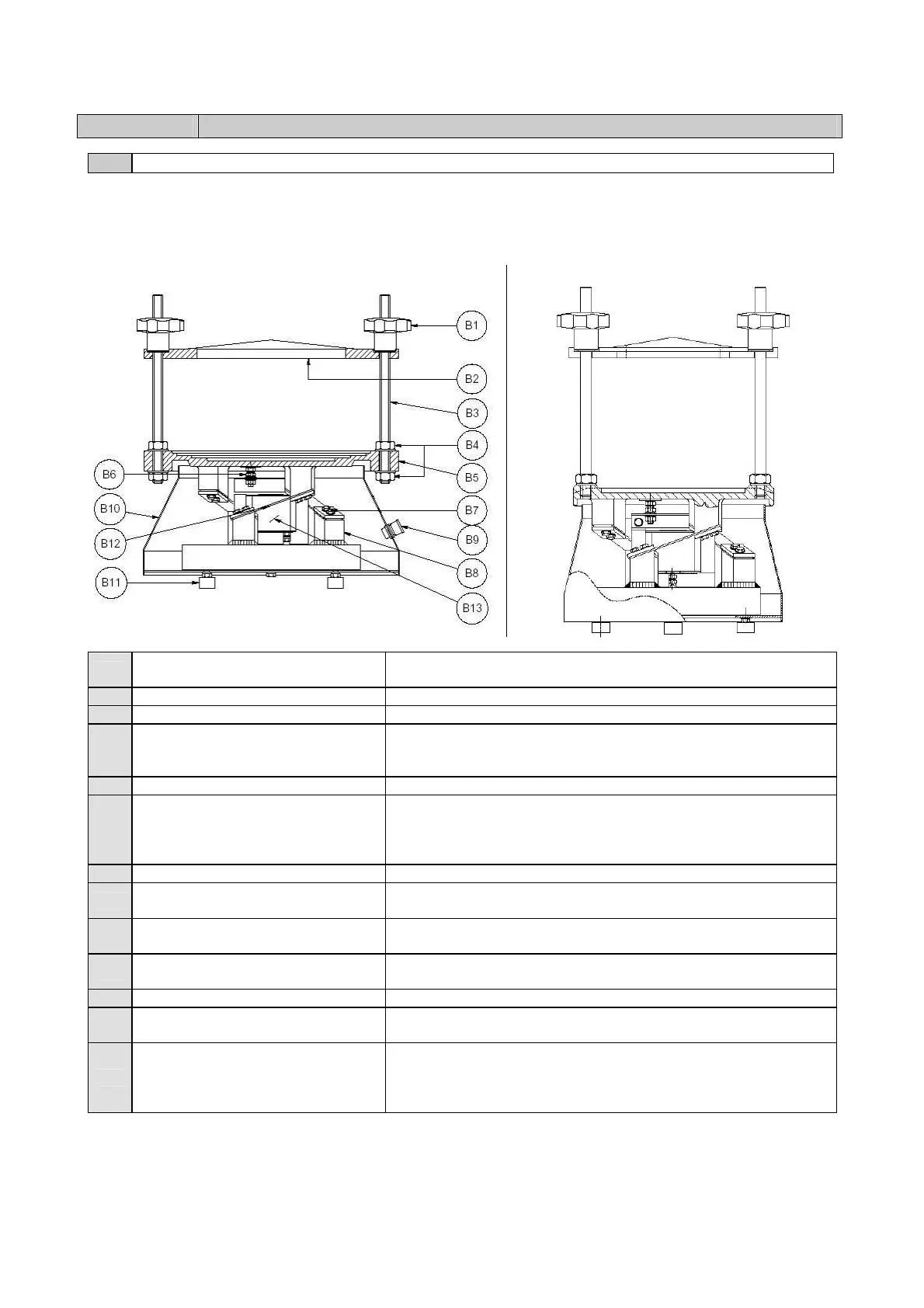

GENERAL MACHINE DESCRIPTION

The equipment is basically formed by a plate holder for specimens (B5). This is supported by springs (B12)

and is activated by electromagnetic impulses (B13). The sieves are subjected to a double vibrating action:

vertical and rotational.

A059-01 KIT

B1

BLOCKING KNOBS

They secure the upper bar (B2) to the sieves, blocking them

firmly to the receiver (B5).

B2

BAR It secures the sieves to the specimen receiver (B5).

B3

THREADED BARS They allow to regulate the bar height (B2).

B4

FIXING NUTS

They fix the threaded bars (B3) to the specimen receiver. In the

shaker A059-01 KIT is present only one pair of data and the bars

B2 are screwed into the sieve holder B5

B5

SIEVE HOLDER It can hold several sieves according to the operator’s needs.

B6

ADJUSTMENT SCREWS

They allow to fix and to adjust the specimen receiver (B5) to the

electromagnet (B13). In this way, the vibrations produced by the

electromagnet are transferred to the sieves placed on the

receiver (B5).

B7

FIXING SCREWS These screws fix the springs (B12) to the support columns (B8).

B8

SUPPORT COLUMN FOR SPRINGS

It allows connecting the base to the specimen receiver (B5) by

means of the springs (B12).

B9

CABLE FIXING DEVICE

It fixes the feeling cable to the sieve shaker base, avoiding its

incidental pull during the normal working procedures.

B10

GUARD

It allows reaching the inside components of the sieve shaker

base. The guard is fixed to the base by some screws.

B11

SUPPORTING FEET They allow laying the sieve shaker steadily on any surface.

B12

SPRINGS

They transfer the vibrations from the electromagnet (B13) to the

specimen receiver (B5).

B13

ELECTROMAGNET

It generates the vibrations, which are necessary for a sieving

test. Using the Control Panel (C) it is possible to modify the

vibrating intensity according to the user’s needs. (See Chapter

“USE” of this manual for further details).

Loading...

Loading...