99903514: TELESCOPIC CRANE: 1-5 SECTION 1: OPERATION

1-4: STARTING CRANE OPERATION

1-4-1: ENGAGING THE POWER TAKE-

OFF (PTO) (IF APPLICABLE)

NOTE:

FOLLOW MANUFACTURER INSTRUC-

TIONS TO ENGAGE THE PTO IN YOUR

VEHICLE. THE INSTRUCTIONS IN THIS

MANUAL MAY NOT BE ACCURATE FOR

ALL PTO’S.

A. Automatic Transmission

1) Set the vehicle parking brake.

2) Turn on the vehicle engine.

3) Put the vehicle in “Park” or “Neutral”.

4) Engage the PTO according to the

manufacturer’s instructions. With an electrical

“Hot Shift” PTO, press the switch to the “ON”

position. NOTE: A light will come on to show the

PTO is engaged.

5) Warm the engine to operating temperature.

6) Begin crane operation.

B. Manual Transmission

1) Set the vehicle parking brake.

2) Place the transmission in “Neutral”.

3) Make certain the PTO lever is in the “OFF”

position.

4) Start the vehicle engine.

5) Fully depress the clutch.

6) Engage the PTO. With a cable-shift PTO,

move the lever to the “ON” position. With an air

shift PTO, move the valve to the “ON” position.

7) Release the clutch gradually.

8) Warm the engine to operating temperature.

9) Begin crane operation.

1-4-2: DISENGAGING THE PTO

1) Fully depress the vehicle’s clutch pedal (if

manual).

2) Disengage the PTO (OFF).

3) Release the clutch pedal gradually.

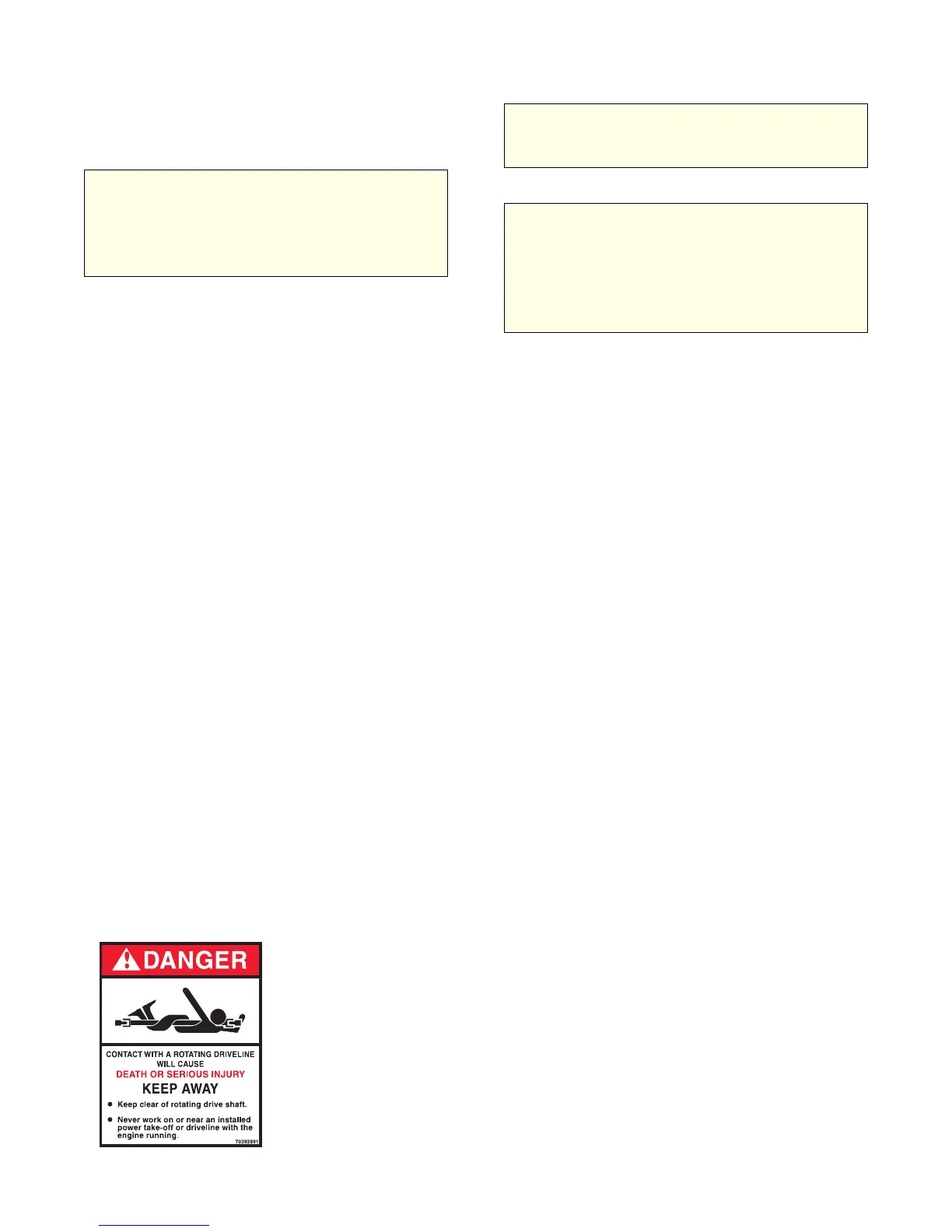

Figure A-5: PTO

Danger Decal

DANGER:

DO NOT COME IN CONTACT WITH THE

PTO. DEATH OR SERIOUS INJURY MAY

OCCUR.

WARNING:

DISENGAGE THE PTO PRIOR TO MOV-

ING THE VEHICLE. FAILURE TO DO SO

MAY CAUSE PUMP AND PTO DAMAGE,

AND INADVERTENT OPERATION OF THE

CRANE DRIVE TRAIN, WHICH COULD

CAUSE AN ACCIDENT.

1-5: ROTATOR WORM GEAR BREAK-IN

Crane models 3020, 3820, 5020, 5025, 5525,

6025 and 6625 have a rotator worm gear.

BEFORE BEGINNING CRANE OPERATION

WITH A NEW WORM GEAR, the gearset must

be well lubricated. Keystone Moly29 Open Gear

Compound is recommended. The molybdenum

disulfide grease must be liberally brushed on the

gear teeth of the bearing and on the teeth of the

worm before any turning of the rotator. All teeth

need to be covered with grease with no exposed

bare metal areas showing. The first rotations of

the rotator may be rough and may have a

scraping sound. This is normal. The gear and

worm are merely breaking in and will smooth

out with continued use. This amount of time

depends on variables including moment load,

cycles of use, slope of boom tilt, etc.

IMT recommends running the system 10-15

cycles with a light load, then 10-15 cycles with a

medium load and finally 10-15 cycles with a

heavy load.

During the break in period, small shavings of

metal may appear in the grease. If this occurs,

the grease with shavings should be removed

from the gear and a new coat of grease is to be

applied to the gear. This will improve rotation

system performance for the life of the system.

20030115

Loading...

Loading...