Form P5710

PARTS, OPERATION AND MAINTENANCE MANUAL

for

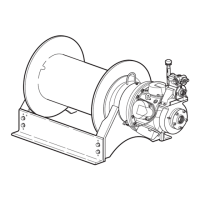

MODEL BU7A AIR WINCH

(Dwg. MHP1233)

Form P5710

Edition 15

May 2001

03523115

© 2001 Ingersoll-Rand Company

READ THIS MANUAL BEFORE USING THESE PRODUCTS. This manual

contains important safety, installation, operation and maintenance

information. Make this manual available to all persons responsible for the

operation, installation and maintenance of these products.

Do not use this Air Winch for lifting, supporting, or transporting people or lifting or

supporting loads over people.

Always operate, inspect and maintain this Air Winch in accordance with American

National Standards Institute safety code (ASME B30.7) and any other applicable safety

codes and regulations.