Description of Function Codes

MD380 User Manual

- 154 -

For CLVC, it is used to adjust the output current of the AC drive with same load.

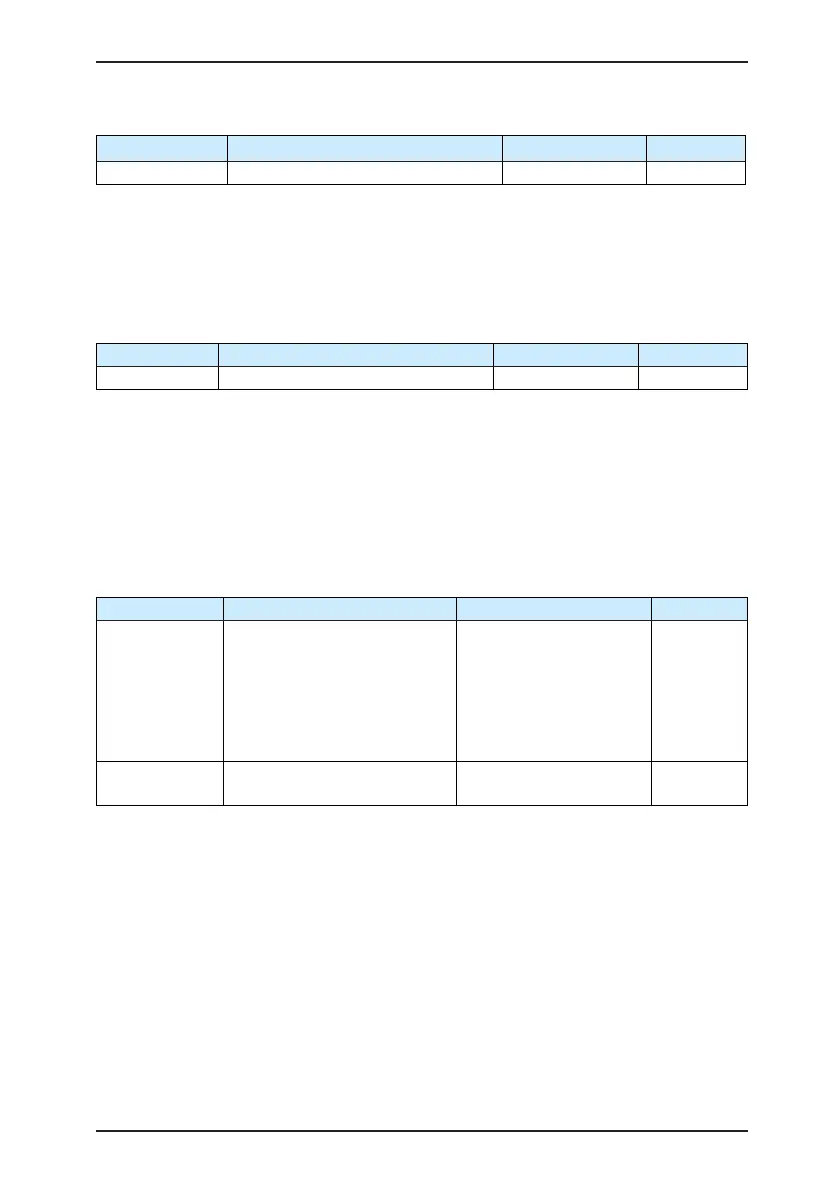

Function Code Parameter Name Setting Range Default

F2-07 Time constant of speed loop lter 0.000–0.100s 0.000s

In the vector control mode, the output of the speed loop regulator is torque current

reference. This parameter is used to lter the torque references. It need not be adjusted

generally and can be increased in the case of large speed uctuation. In the case of motor

oscillation, decrease the value of this parameter properly.

If the value of this parameter is small, the output torque of the AC drive may fluctuate

greatly, but the response is quick.

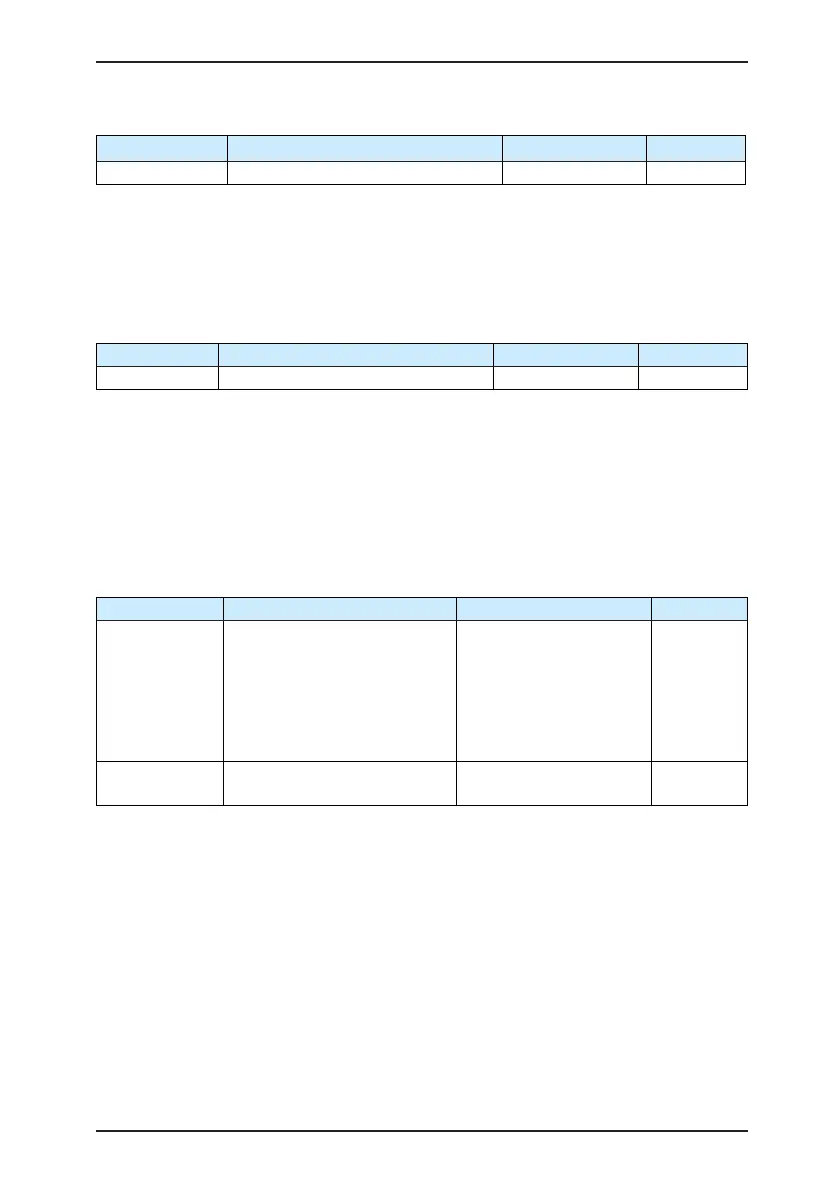

Function Code Parameter Name Setting Range Default

F2-08 Vector control over-excitation gain 0–200 64

During deceleration of the AC drive, over-excitation control can restrain rise of the bus

voltage to avoid the overvoltage fault. The larger the over-excitation gain is, the better the

restraining effect is.

Increase the over-excitation gain if the AC drive is liable to overvoltage error during

deceleration. Too large over-excitation gain, however, may lead to an increase in output

current. Therefore, set this parameter to a proper value in actual applications.

Set the over-excitation gain to 0 in applications of small inertia (the bus voltage will not rise

during deceleration) or where there is a braking resistor.

Function Code Parameter Name Setting Range Default

F2-09

Torque upper limit source in

speed control mode

0: F2-10

1: AI1

2: AI2

3: AI3

4: Pulse setting (DI5)

5: Communication setting

0

F2-10

Digital setting of torque upper

limit in speed control mode

0.0%–200.0% 150.0%

In the speed control mode, the maximum output torque of the AC drive is restricted by F2-

09. If the torque upper limit is analog, pulse or communication setting, 100% of the setting

corresponds to the value of F2-10, and 100% of the value of F2-10 corresponds to the AC

drive rated torque.

For details on the AI1, AI2 and AI3 setting, see the description of the AI curves in group F4.

For details on the pulse setting, see the description of F4-28 to F4-32.

When the AC drive is in communication with the master, if F2-09 is set to 5 “communication

setting”, F2-10 “Digital setting of torque upper limit in speed control mode” can be set via

communication from the master.

In other conditions, the host computer writes data -100.00% to 100.00% by the

communication address 0x1000, where 100.0% corresponds to the value of F2-10. The

communication protocol can be Modbus, CANopen, CANlink or PROFIBUS-DP.

Loading...

Loading...