MD380 User Manual Product Information

- 21 -

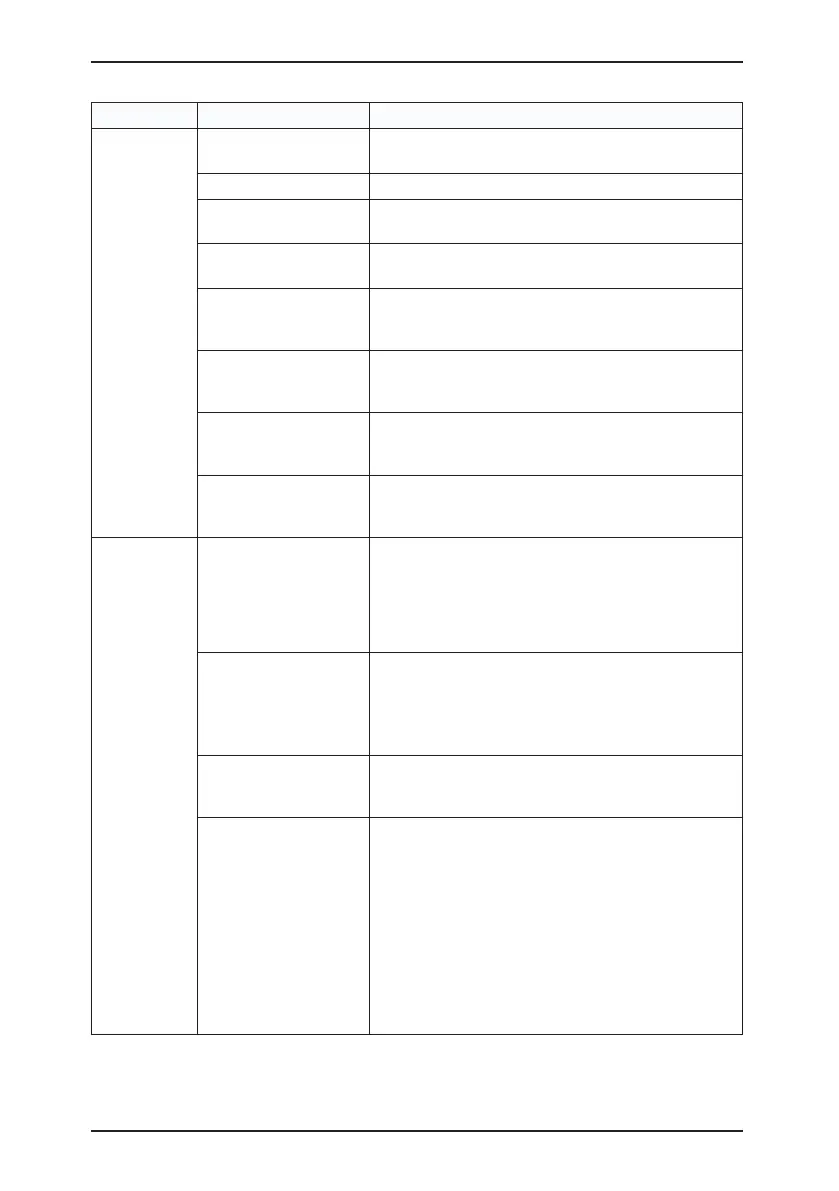

Item Specications

Individualized

functions

Virtual I/Os

Five groups of virtual DI/Dos can realize simple logic

control.

Timing control Time range: 0.0–6500.0 minutes

Multi-motor switchover

Four motors can be switched over via four groups of

motor parameters.

Multiple communication

protocols

It supports communication via Modbus-RTU,

PROFIBUS-DP, CANlink and CANopen.

Motor overheat

protection

The optional I/O extension card enables AI3 to receive

the motor temperature sensor input (PT100, PT1000)

so as to realize motor overheat protection.

Multiple encoder types.

It supports various encoders such as differential

encoder, open-collector encoder, resolver and UVW

encoder.

User programmable

function

The optional programming card helps you to realize

secondary development. Its programming environment

is compatible with that of the PLC of Inovance.

Advanced background

software

It supports the operation of AC drive parameters and

virtual oscillograph function, via which the state inside

the AC drive is monitored.

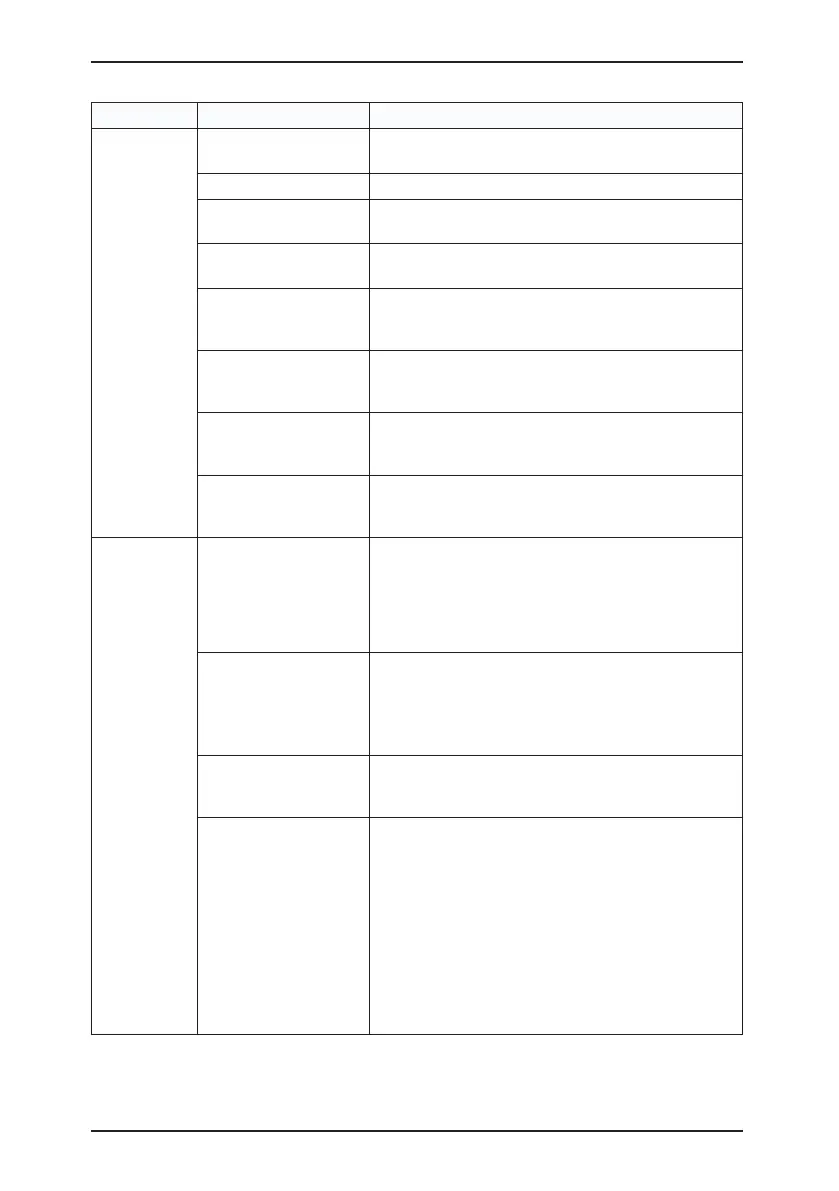

RUN

Running command

source

• Operation panel

• Control terminals

• Serial communication port

You can perform switchover between these sources in

various ways.

Frequency source

There are a total of 10 frequency sources, such as digital

setting, analog voltage setting, analog current setting,

pulse setting and serial communication port setting.

You can perform switchover between these sources in

various ways.

Auxiliary frequency

source

There are ten auxiliary frequency sources. It can

implement ne tuning of auxiliary frequency and

frequency synthesis.

Input terminal

Standard:

• 5 digital input (DI) terminals, one of which supports

up to 100 kHz high-speed pulse input5

•

2 analog input (AI) terminals, one of which only

supports 0–10 V voltage input and the other supports

0–10 V voltage input or 4–20 mA current input

Expanding capacity:

• 5 DI terminals

• 1 AI terminal that supports -10–10 V voltage input

and also supports PT100\PT1000

Loading...

Loading...