Product Information MD380 User Manual

- 22 -

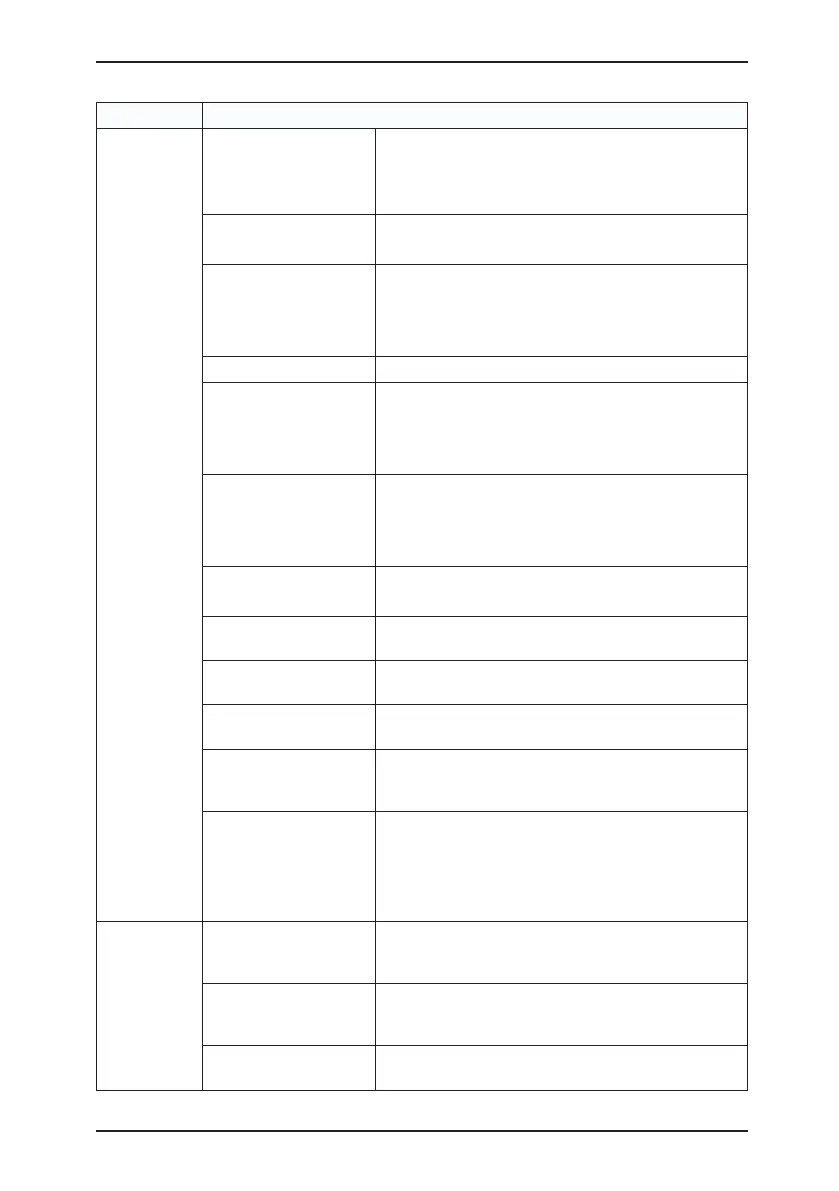

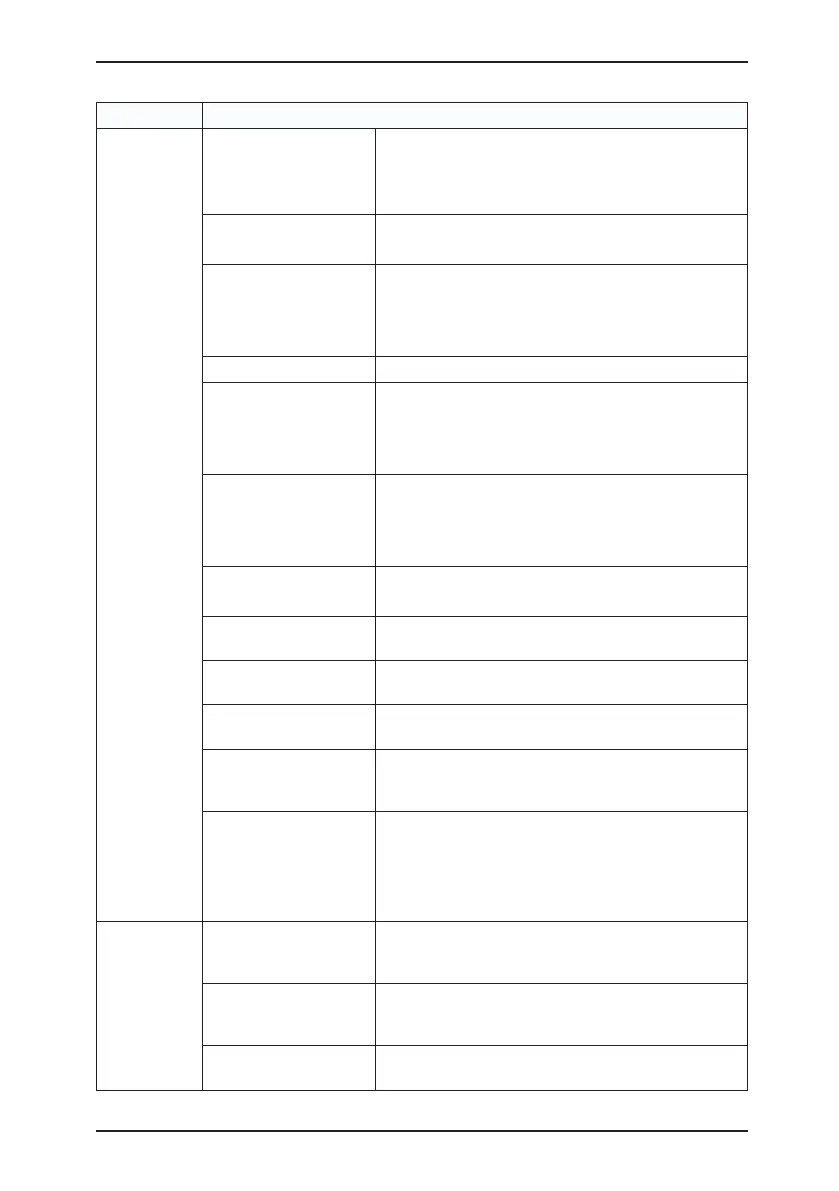

Item Specications

Standard

functions

Overload capacity

• G type: 60s for 150% of the rated current, 3s for

180% of the rated current

• P type: 60s for 120% of the rated current, 3s for

150% of the rated current

Torque boost

• Fixed boost

• Customized boost 0.1%–30.0%

V/F curve

• Straight-line V/F curve

• Multi-point V/F curve

• N-power V/F curve (1.2-power, 1.4-power,

1.6-power, 1.8-power, square)

V/F separation Two types: complete separation; half separation

Ramp mode

• Straight-line ramp

• S-curve ramp

Four kinds of acceleration/deceleration time with the

range of 0.0–6500.0s

DC braking

• DC braking frequency: 0.00 Hz to maximum

frequency

• Braking time: 0.0–36.0s

• Braking action current value: 0.0%–100.0%

JOG control

• JOG frequency range: 0.00–50.00 Hz

• JOG acceleration/deceleration time: 0.0–6500.0s

Onboard multiple preset

speeds

It implements up to 16 speeds via the simple PLC

function or combination of DI terminal states.

Onboard PID

It realizes process-controlled closed loop control

system easily.

Auto voltage regulation

(AVR)

It can keep constant output voltage automatically

when the mains voltage changes.

Overvoltage/

Overcurrent stall control

The current and voltage are limited automatically

during the running process so as to avoid frequent

tripping due to overvoltage/overcurrent.

Torque limit and control

It can limit the torque automatically and prevent

frequent over current tripping during the running

process.

Torque control can be implemented in the CLVC mode.

Individualized

functions

High performance

Control of asynchronous motor and synchronous

motor are implemented through the high-performance

current vector control technology.

Power dip ride through

The load feedback energy compensates the voltage

reduction so that the AC drive can continue to run for

a short time.

Rapid current limit

It helps to avoid frequent overcurrent faults of the AC

drive.

Loading...

Loading...