MD380 User Manual Desc

ription of Function Codes

- 237 -

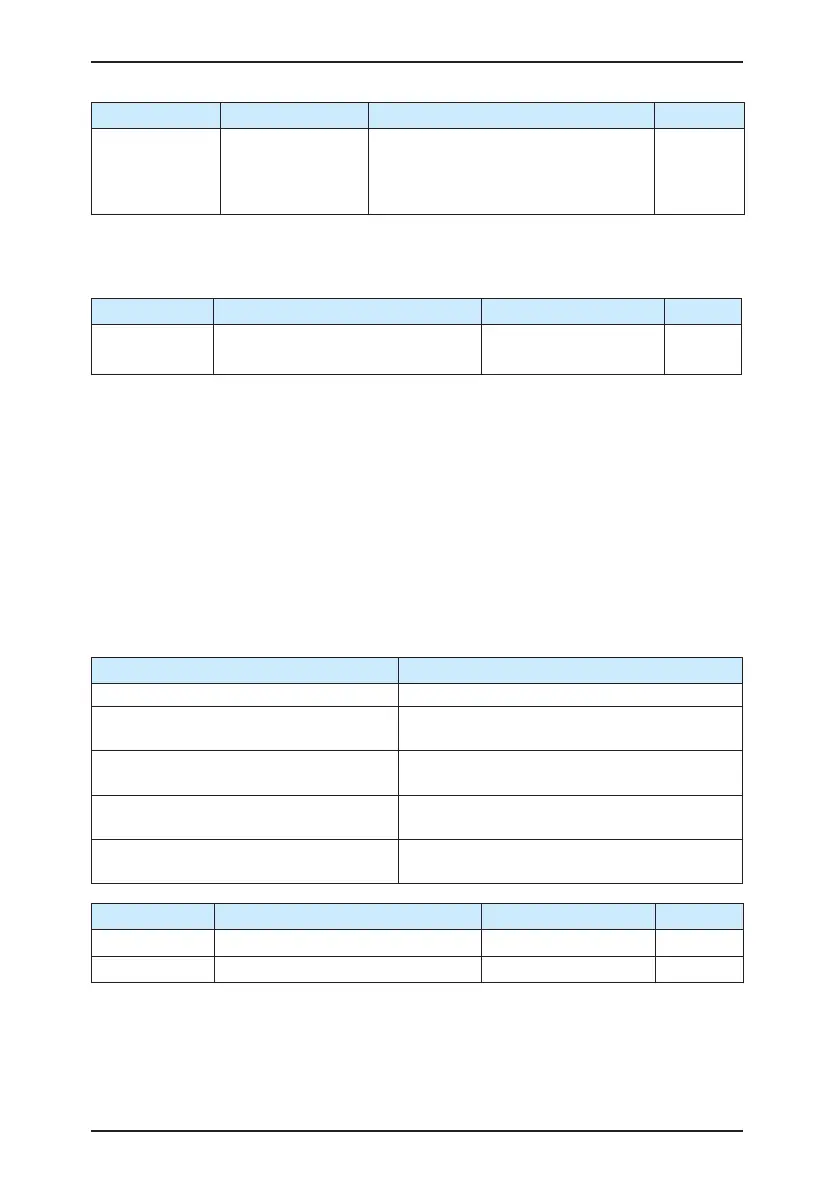

Function Code Parameter Name Setting Range Default

A8-02

Slave following

master command

selection

0: Slave not following running

commands of the master

1: Slave following running commands

of the master

0

When A8-01 (Master and slave selection) is set to 1 (Slave) and F0-02 (Command source

selection) is set to 2 (Communication control), if A8-02 is set to 1, the salve follows the

master to start or stop.

Function Code Name Setting Range Default

A8-03 Usage of data received by slave

0: Torque setting

1: Frequency setting

0

It is used to determine whether the slave uses data received from the master for torque

setting or frequency setting. This function can be used only when the frequency source or

torque source must be communication setting.

When the AC drive is a slave in point-point communication and receives data for torque

setting, 100.00% of the received data corresponds to 200.0% of torque setting, unrelated

to A0-03. If zero offset of the slave is 0.00% and the gain is 1.00, it means that the slave

directly takes the output torque of the master as the target torque.

When the AC drive is a slave in point-point communication and receives data for frequency

setting, 100.00% of the received data corresponds to the value of F0-10 (Maximum frequency).

For example, to balance the load, do the following settings.

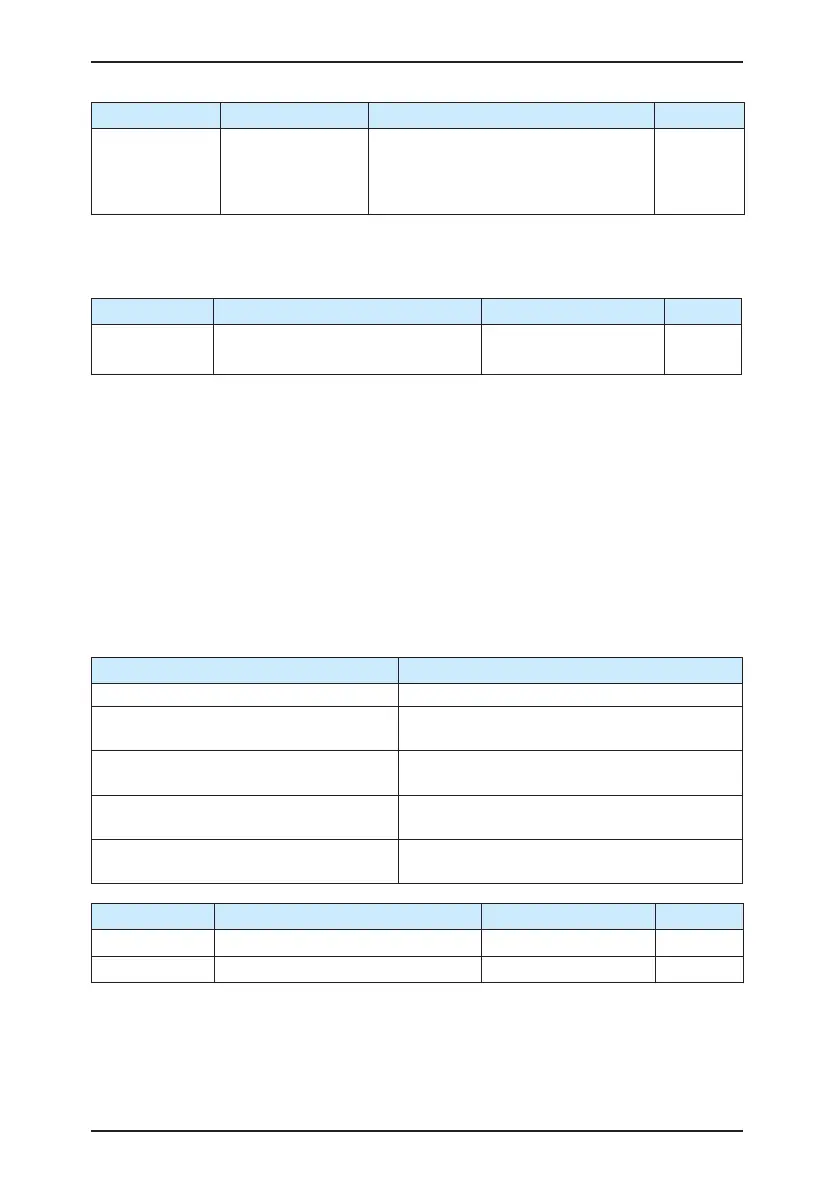

Table 6-14 Settings for balancing the load

Master Slave

A0-00 = 0: Speed control A0-00 = 1: Torque control

A8-00 = 1: Point-point communication

enabled

A8-00 = 1: Point-point communication enabled

A8-01 = 0: Master in point-point

communication

A8-01 = 1: Slave in point-point communication

A8-02 = 0: Data source from master being

output torque

A8-03 = 0: Slave receiving data for torque setting

A0-01 = 5: Torque source in torque control set to

communication setting

Function Code Parameter Name Setting Range Default

A8-04 Zero offset of received data (torque) -100.00%–100.00% 0.00%

A8-05 Gain of received data (torque) -10.00–10.00 1.00

These two parameters are used to adjust data received from the master and define the

torque reference relationship between the master and the slave.

Loading...

Loading...