23

Jaw Faces

Product Support: www.instron.com

Do not use serrated jaw faces to test specimens with a hardness greater than 50

Rockwell C. The serrations may not penetrate extremely hard specimens; also, hard

specimens will cause excessive serration wear.

The following are common jaw face specifications:

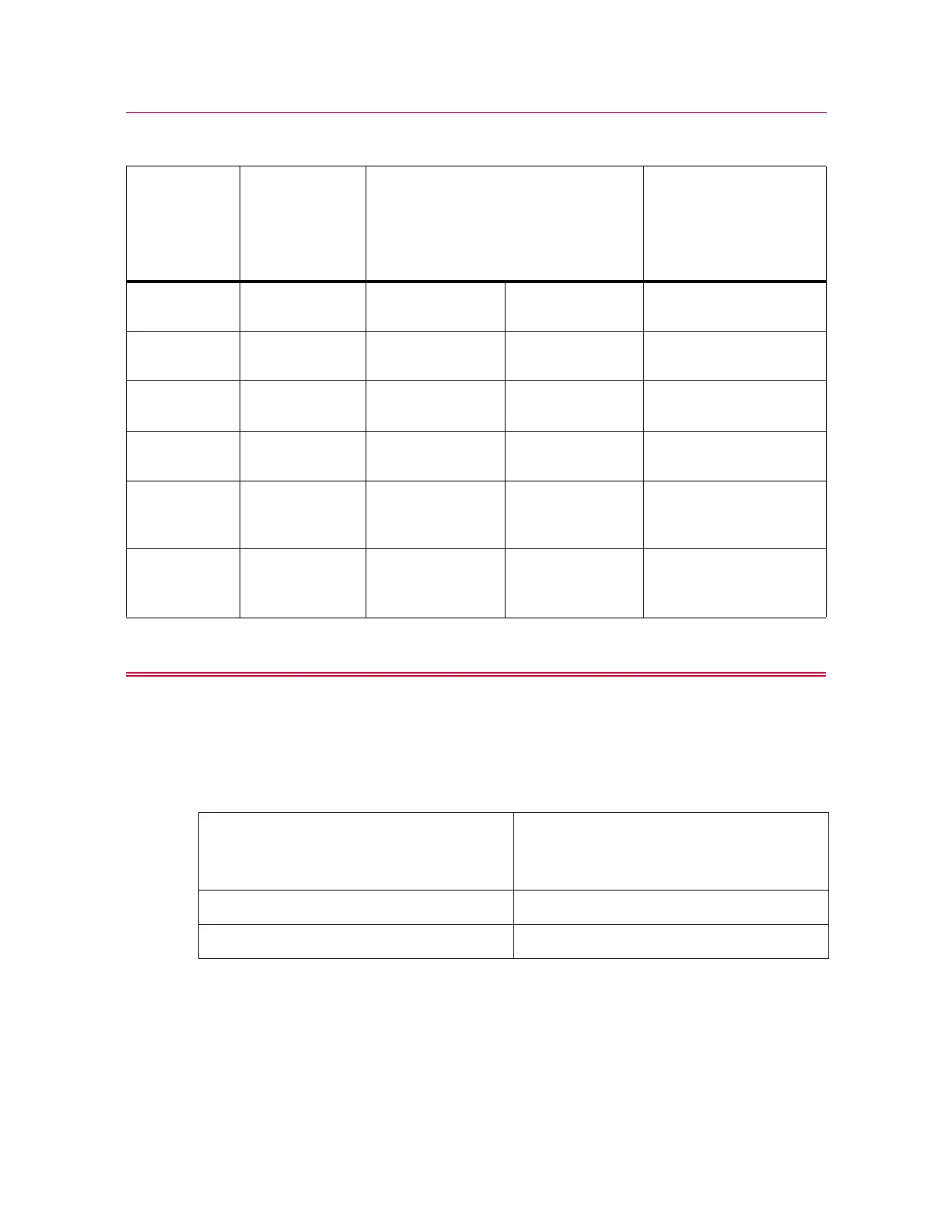

2703-156 Flat 6.4 to 12.6

(0.25 to 0.50)

11.4 to 17.6

(0.45 to 0.70)

1mm pitch (25 teeth per

in.)

2703-157 Flat 0 to 6.4

(0 to 0.25)

5 to 11.4

(0.20 to 0.45)

Surfalloy coated (emery

grit of 100)

2703-158 Flat 6.4 to 12.6

(0.25 to 0.50)

11.4 to 17.6

(0.45 to 0.70)

Surfalloy coated (emery

grit of 100)

2703-160 Flat 0 to 6.4

(0 to 0.25)

5 to 11.4

(0.20 to 0.45)

Rubber coated (emery

grit of 100)

2703-153 Round 3.2 to 7.8

(0.12 to 0.31)

Diameter

8.2 to 12.8

(0.32 to 0.50)

Diameter

1mm pitch (25 teeth per

in.)

2703-154 Round 7.1 to 12.6

(0.28 to 0.50)

Diameter

12.1 to 17.6

(0.48 to 0.70)

Diameter

1mm pitch (25 teeth per

in.)

Table 4. 2716-020 (50 kN) Ranges for Specimen Thickness (Continued)

Catalog

Number

Specimen

Type Specimen Thickness Surface

With Spacers

mm (in)

Without Spacers

mm (in)

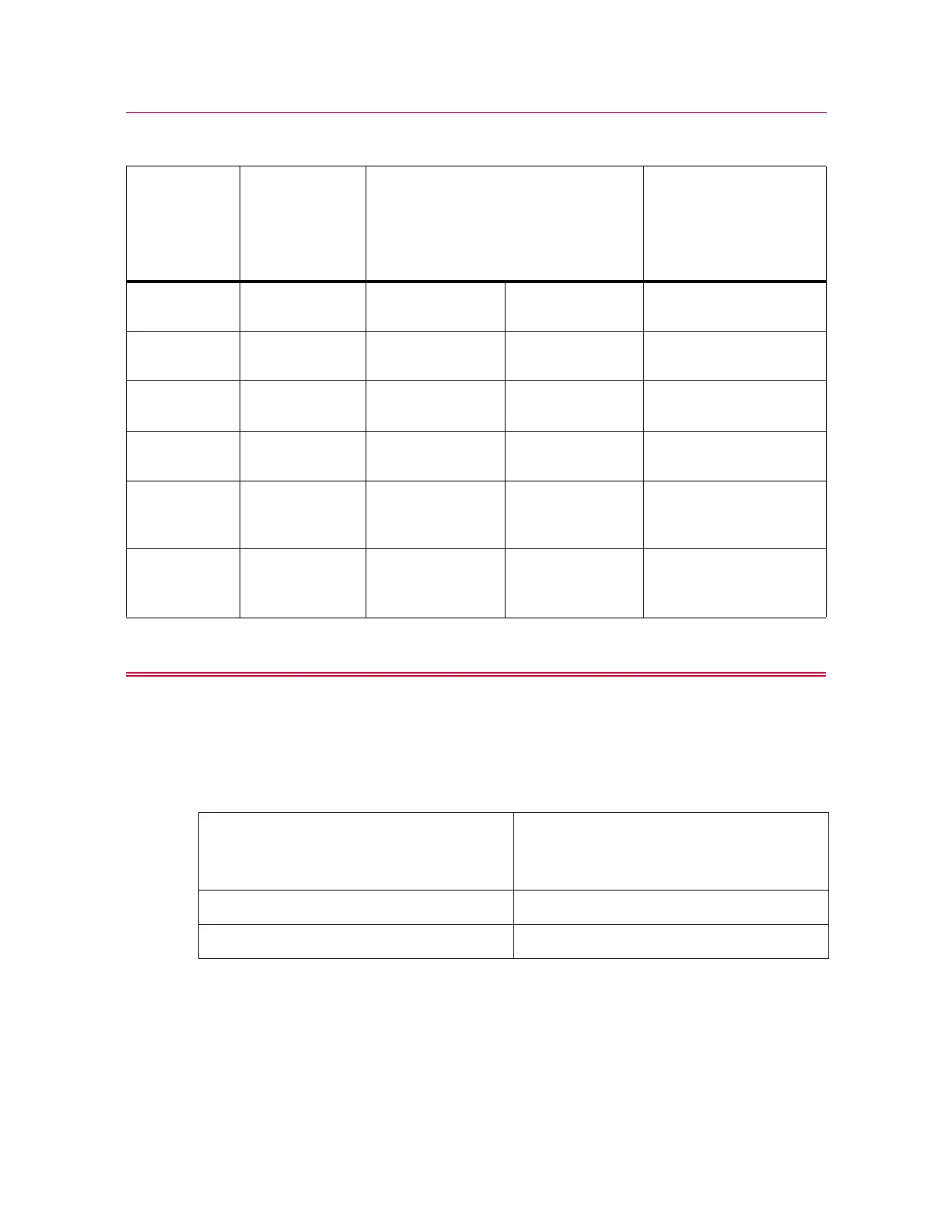

Parameter Specification

Construction Tool steel

Height 57 mm (2.2 in.)

Width 25 mm (1 in.)

Loading...

Loading...