E-Mail: keiths@interfaceforce.com

Technical changes reserved

TS Series Reaction Torque.doc

Internet: www.interfaceforce.com

2 Term Definitions

2.1 Terms

Measuring Side:

Shaft connection in which the torque to be measured is applied. Usually this side has the smallest

moment of inertia.

Drive Side:

The shaft end on the opposite side of the measuring side with the larger moment of inertia.

At static torque sensors the housing is fastened on this side.

Low Torque Resistance Side:

The shaft of the arrangement (drive, load) which can be turned considerably smaller with torque than the

nominal torque of the torque sensor M << M

nenn

.

2.2 Definition of the Pictograms on the Torque Sensor

The measuring side of the torque sensor is designated as follows:

More information can be found on the data sheet if needed.

3 Product Description

The sensor measures static and dynamic torques. The mounting position of the torque sensor is

horizontally or vertically.

Caution: it is to be differentiated between measuring side and drive side, see data sheet of the sensor:

http://www.interfaceforce.

com

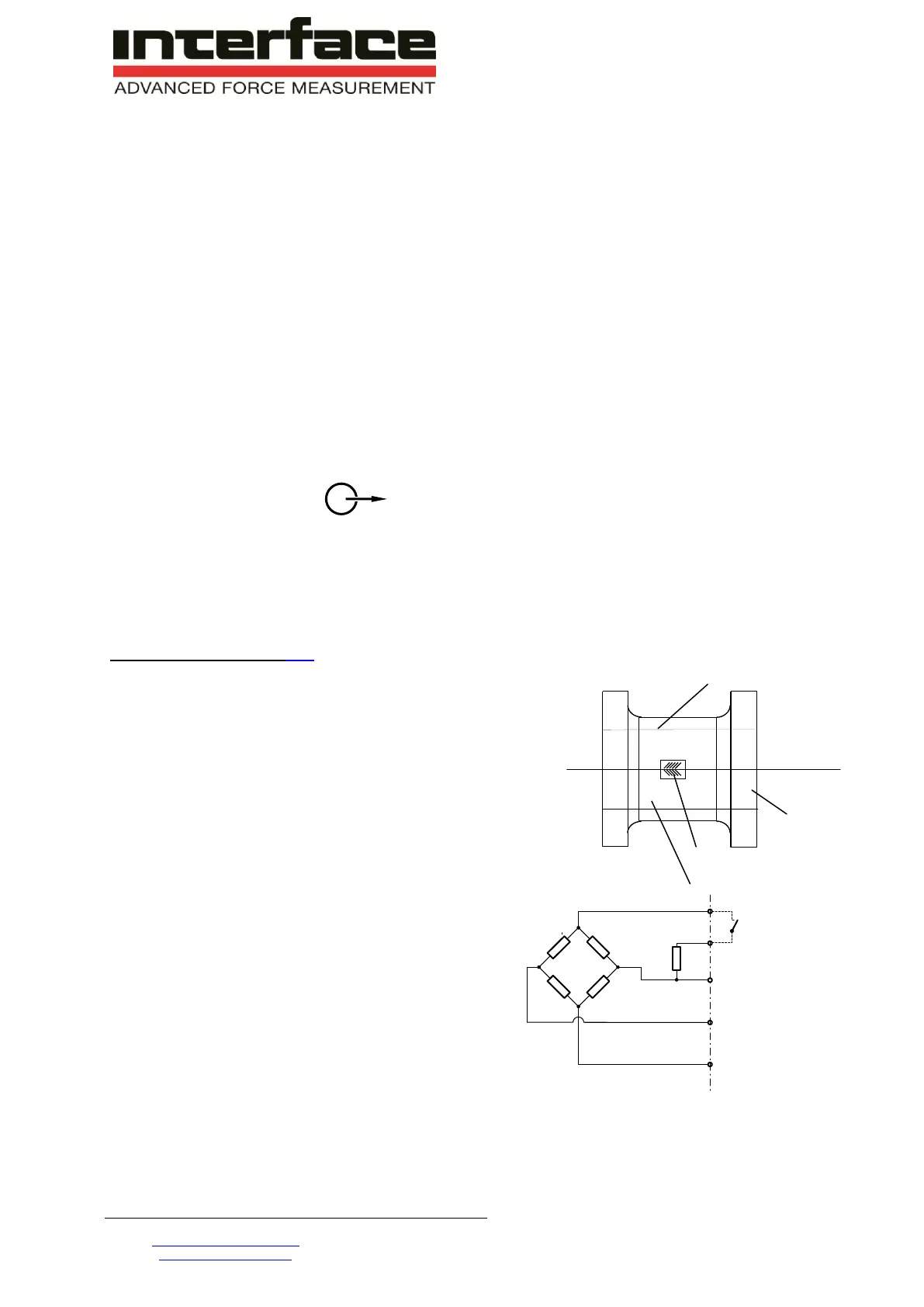

3.1 Mechanical Setup

The sensors do not contain rotary parts.

They consist of a torsion body with different connection

possibilities (flanges, shafts, square, hexagonal etc.). The

torsion body, applied with strain gauges, is protected by a

housing. A plug or a cable connection is fixed at the housing.

3.2 Electrical Setup

The strain gauge full bridge is directly connected at the

plug or at the cable.

Optionally a calibration control can be integrated. For

this, the SG full bridge gets detuned by an external

switch in such a way, that at the output the measuring

signal, which is corresponding to the positive nominal

torque, can be measured.

R

k

R

1

R

2

R

4

R

3

Supply +

Control

Signal +

Signal -

Supply -

external switch

SG

Sensor External

Basic sketch of the strain gauge full bridge

with option calibration control

Loading...

Loading...